A large tank outer wall polishing device

A technique for polishing devices and tanks, which is applied to surface polishing machine tools, grinding/polishing equipment, automatic grinding control devices, etc., and can solve problems such as high cost, time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

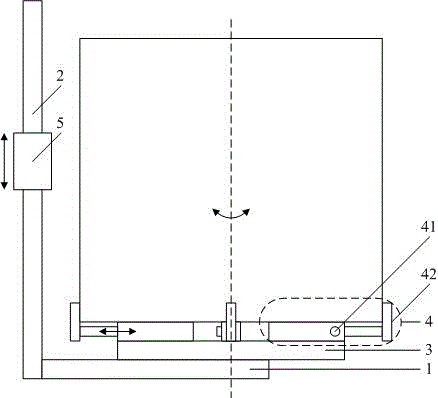

[0022] The large-scale tank outer wall polishing device of the present embodiment has a structural schematic diagram as figure 1 shown. The large tank external wall polishing device includes a horizontal axis 1, a vertical axis 2 and a control box,

[0023] The outer end of the horizontal shaft 1 is provided with a swivel 3 that rotates in the horizontal plane, and the swivel 3 is provided with a plurality of telescopic rods 4, and each telescopic rod 4 is provided with a first locking mechanism 41, each The outer ends of the telescopic rods 4 are provided with protrusions 42;

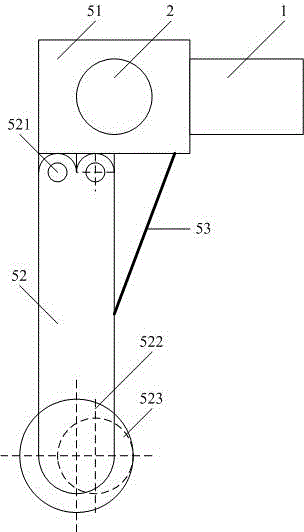

[0024] Described longitudinal axis 2 is provided with the polisher 5 that moves up and down along longitudinal axis (2), in figure 1 In , the polisher 5 is only schematically drawn. The concrete structure of polisher 5 is as figure 2 As shown, it incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com