General clamp for abrasive flow polishing of complicated hole surface

An abrasive flow and hole surface technology, applied in the direction of grinding workpiece supports, can solve the problems of fixture design, increased manufacturing workload, poor economy, waste of manpower and material resources, etc., and achieves low cost, universal fixtures, and wide adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

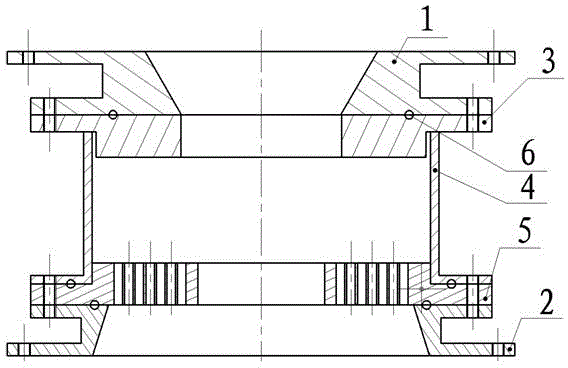

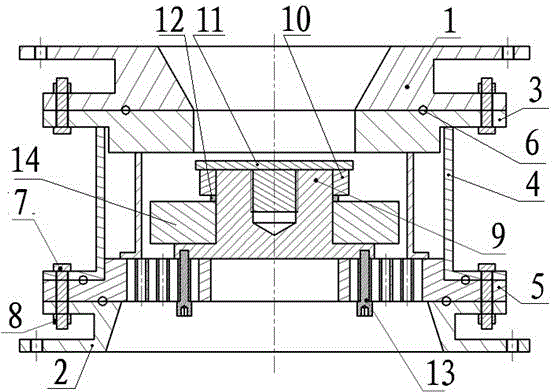

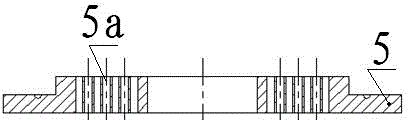

[0015] Examples of the present invention figure 1 , figure 2 , image 3 , Figure 4 As shown, this embodiment includes a clamp body, an embedded module, and bolts 13; the clamp body includes a lower guide sleeve 1, an upper guide sleeve 2, a lower pressure plate 3, a sleeve 4, an upper pressure plate 5, a sealing ring 6, and a bolt 7. , nut 8; the upper pressure plate 5 has a built-in module connection hole 5a, and the abrasive flow channel hole 5b distributed in the circumferential radial direction; the upper pressure plate 5 abrasive flow channel hole 5b is axially parallel to the polished surface of the polished workpiece 14; The sleeve 2, the upper pressure plate 5 and the sleeve 4 are tightly connected; the sealing ring 6 is installed between the joint surface between the lower guide sleeve 1 and the lower pressure plate 3, the lower guide s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com