Roller kiln and spray tower negative pressure exhaust pipeline emergency emptying mechanics mechanism

A technology for exhaust ducts and spray towers, applied in furnaces, furnace components, waste heat treatment, etc., can solve problems such as system operation risks, and achieve continuous and stable pressure and flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

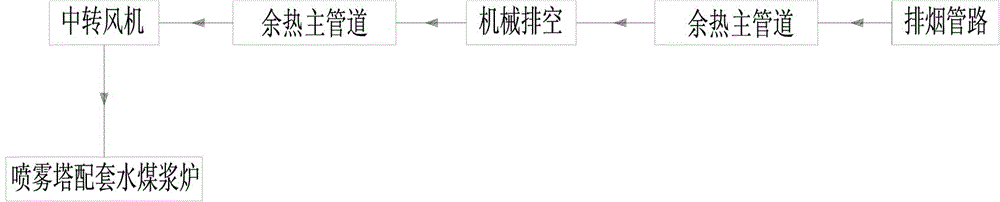

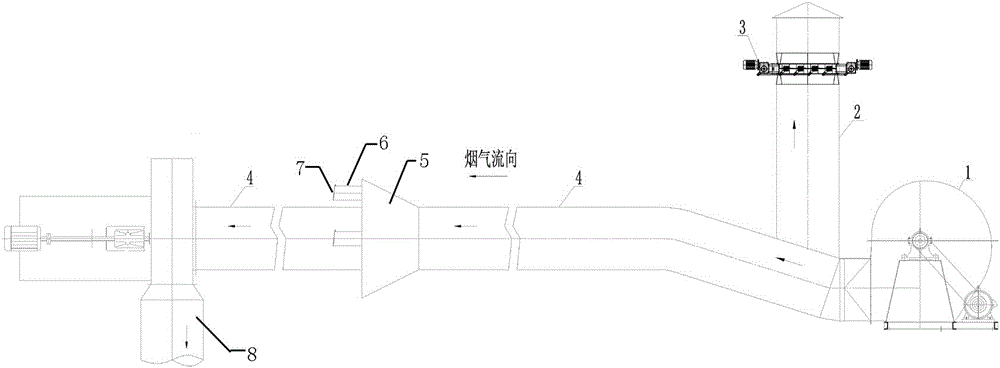

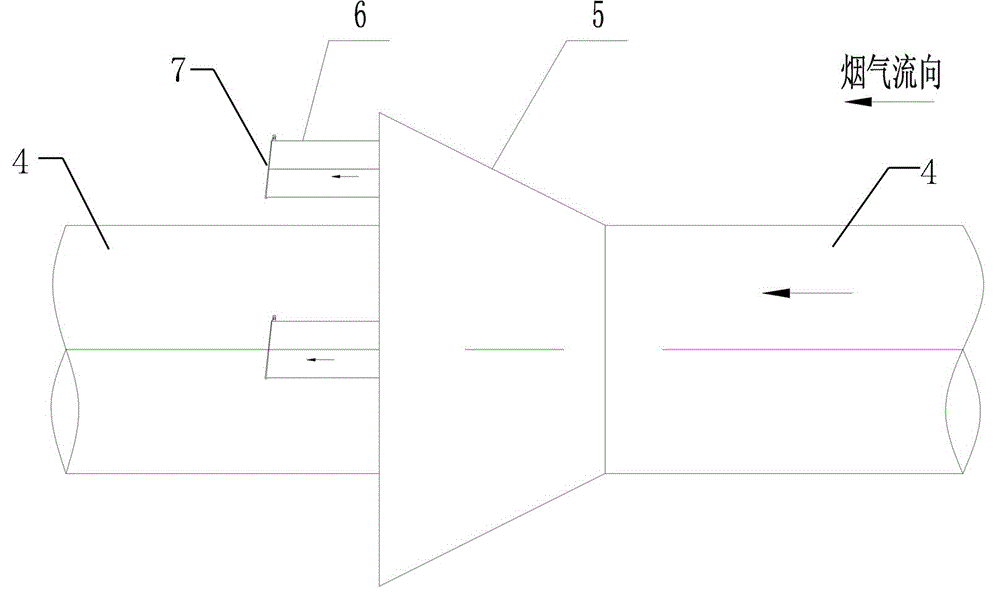

[0022] figure 1 It is a working principle diagram of the emergency emptying mechanical mechanism of a roller kiln-spray tower negative pressure suction and exhaust duct of the present invention, figure 2 is its overall structure diagram, image 3 and Figure 4 It is the structural diagram of the emptying tubule mechanism and its front view. The present invention relates to a roller kiln-spray tower negative pressure suction and exhaust pipeline emergency evacuation mechanical mechanism, including a smoke exhaust pipeline, a waste heat main pipeline 4, a mechanical evacuation mechanism and a transfer fan 8. The smoke exhaust pipe is composed of a smoke exhaust fan 1, an emptying pipe 2, and an electric emptying valve 3; the mechanical emptying mechanism is composed of a conical pipe 5, several sets of small emptying pipes 6, and a plug-type movable cover 7, in which the small emptying pipe 6 Section angle λ<90 degrees; waste heat main pipeline 4 is a circular tube.

[0023...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com