Spring support plate, fracture device and dividing method

An elastic support and breaking technology, applied in the direction of fine working devices, working accessories, manufacturing tools, etc., can solve the problems of shortening processing time, inability to reduce costs, and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

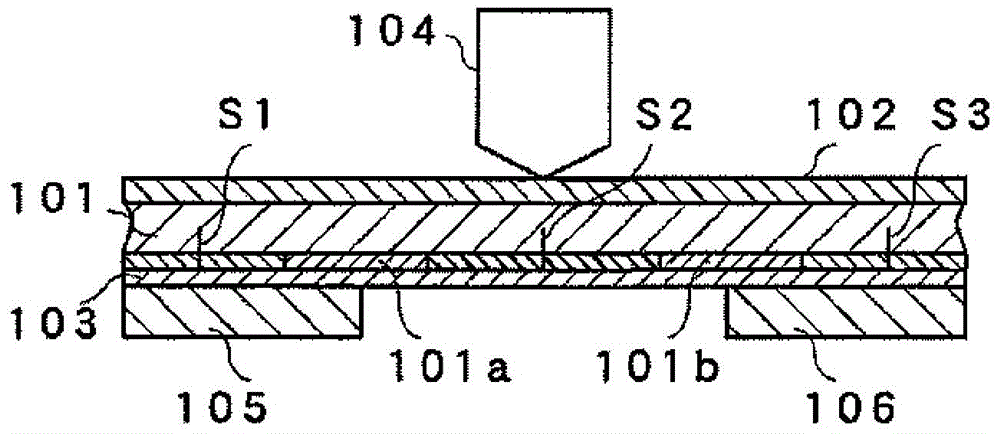

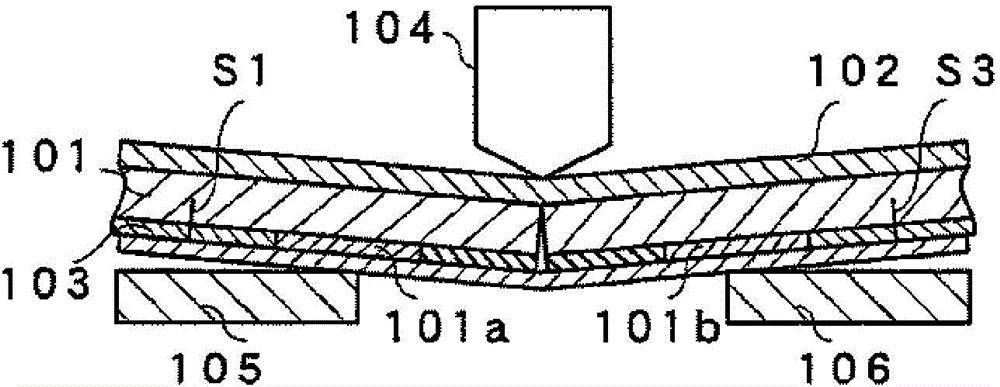

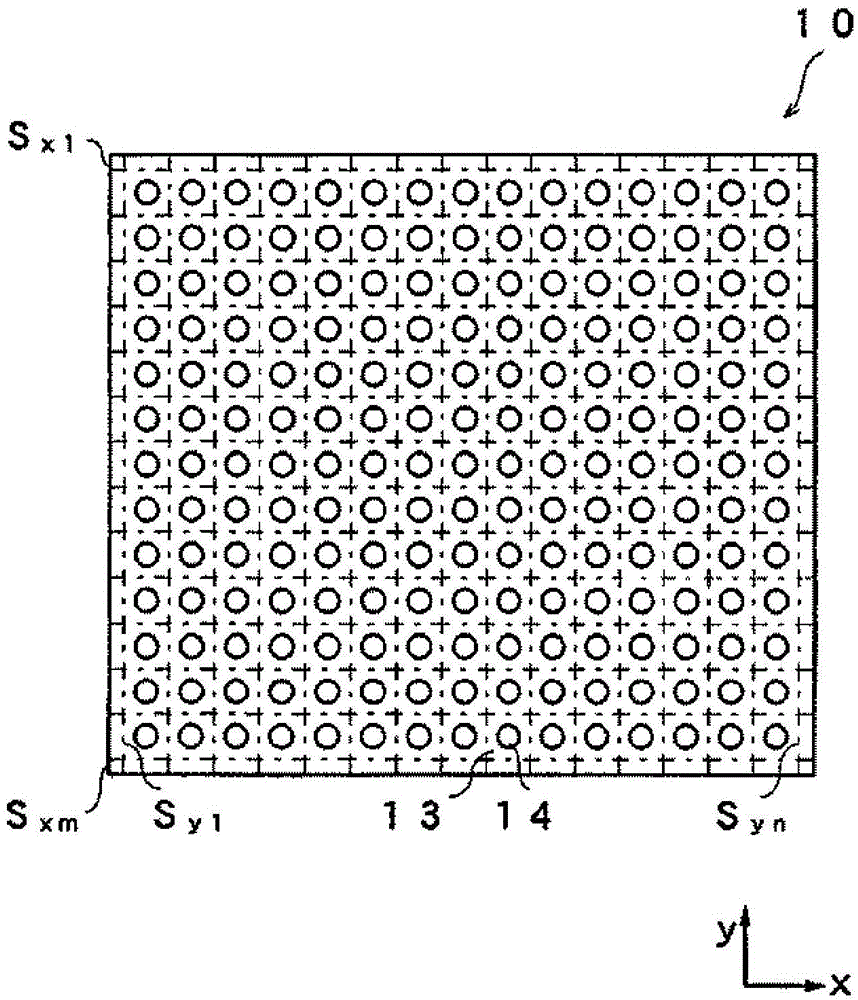

[0026] Next, embodiments of the present invention will be described. 2( a ) and 2( b ) show a front view and a side view of a composite substrate 10 on which a rectangular semiconductor element is mounted as an example of such a substrate. In this embodiment, a composite substrate 10 in which a resin layer, for example, a silicone resin 12 is coated on a ceramic substrate 11 is used as a cutting object. Here, the division of only the ceramic substrate 11 of the composite substrate 10 is performed at one time by making the scribe penetrate vertically into the substrate, so this division is expressed as "fracture", while the division of the silicone resin layer 12 is performed by Since the cracks in the resin layer are gradually expanded and split by applying force, this breaking is expressed as "broken". In addition, the breaking of the composite substrate 10 as a whole is expressed as "breaking". In the manufacturing process of the composite substrate 10 , a plurality of fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com