Multi line cutting machine swing drive structure

A technology of multi-wire cutting machine and drive structure, which is applied in the direction of working accessories, fine working devices, stone processing equipment, etc., can solve the problems of large volume and moment of inertia of the swing head, reduced fatigue life of parts, complex structure assembly requirements, etc. Achieve the effects of avoiding poor sealing problems, reducing structural weight, and operating responsively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

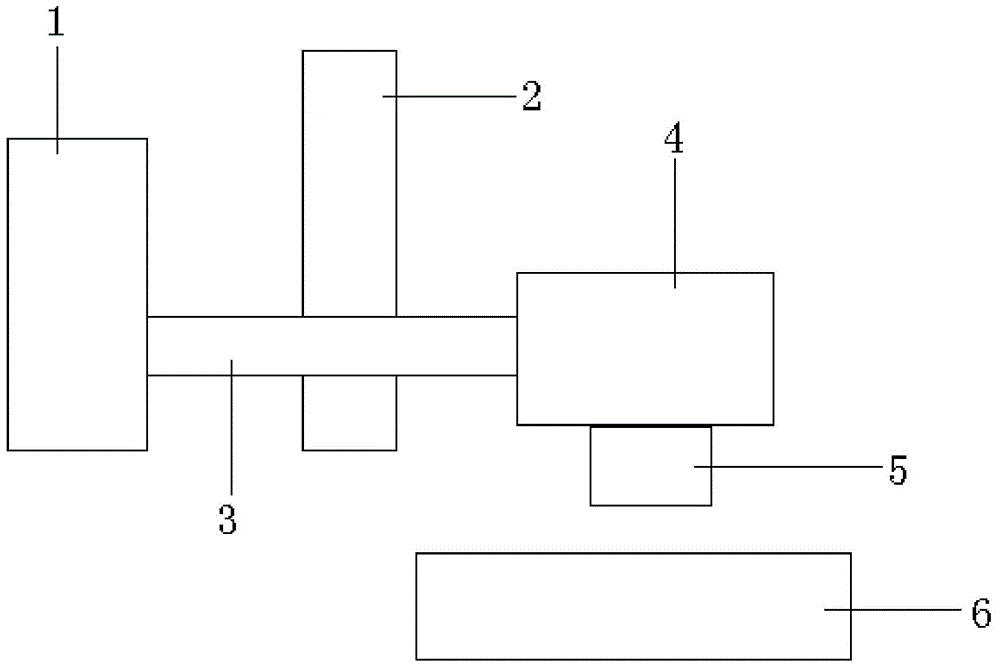

[0011] Such as figure 1 As shown, a swing drive structure for a multi-wire cutting machine described in the embodiment of the present invention includes: a transmission part 3, a power part 1 is installed at the front end of the transmission part 3, and a swing is installed at the rear end of the transmission part 3. Head 4, the vertical movement part 2 is installed in the middle of the transmission part 3; the workpiece sapphire rod 5 is clamped in the lower part of the swing head 4; the cutting mesh wire 6 is located directly below the swing head 4. This new structure reduces the links such as gear transmission and swinging guide rail sliders in the traditional swing mechanism, and can avoid the gap and error accumulation in the links, thereby greatly improving the precision of swing cutting; this structure combines the key power part and transmission part. Together with the up and down movement parts, they are all placed on one side of the swing head, which greatly simplifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com