Self-sealing diaphragm integral riveting spring brake air chamber

A spring brake air chamber, self-sealing technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problem of the large shape of the clamp-connected brake air chamber, unfavorable mass production, and fit clearance changes, etc. problems, to achieve the effect of increasing the technical effect of air tightness, high degree of automatic assembly, and convenient automatic assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

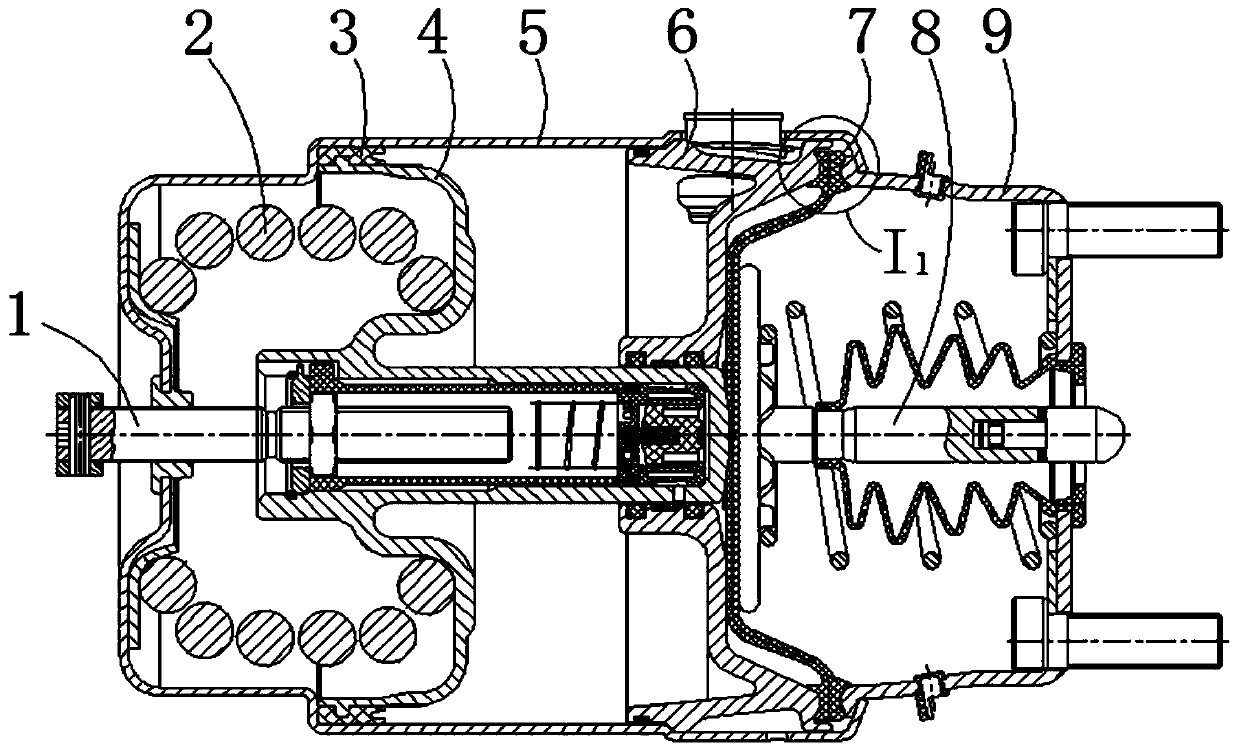

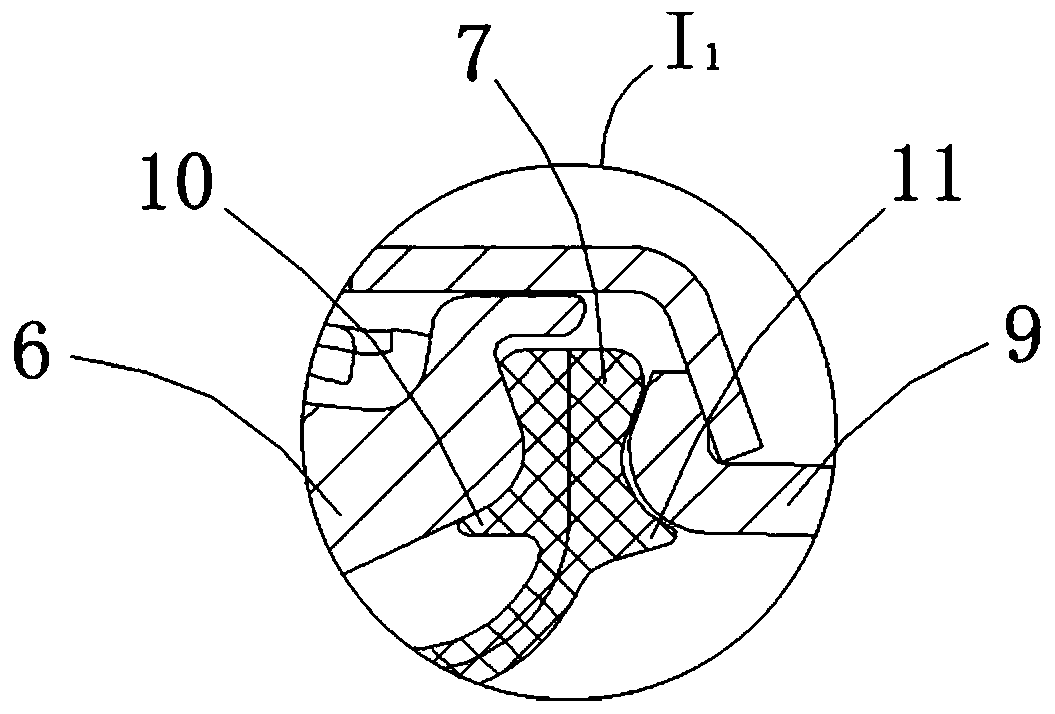

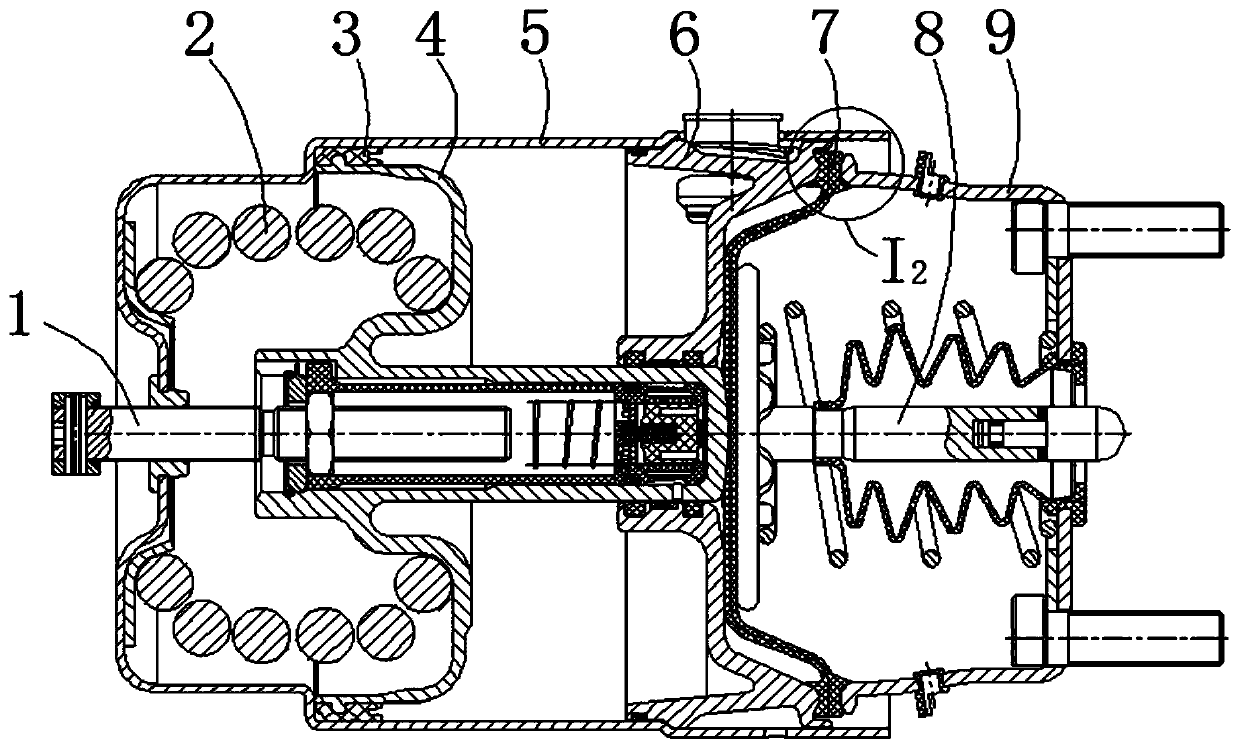

[0029] Combine below Figure 1-4 Describe in detail the technical solution of the integral riveted spring brake air chamber of the self-sealing diaphragm:

[0030] A self-sealing diaphragm integral riveting type spring brake air chamber, including tie rod bolt 1, spring 2, Y-shaped ring 3, piston 4, cylinder body 5, middle casing 6, diaphragm 7, push plate 8, end Cover 9, cylinder body 5 includes cavity and is provided with opening, and cylinder body 5 adopts the stamping of steel plate to form, and pull rod bolt 1, spring 2, Y ring 3, piston 4, cylinder body 5, middle housing 6, membrane The sheet 7, the push plate 8, and the end cover 9 are positioned and installed in sequence according to the assembly sequence and pre-pressed into the cavity to form a parking cavity and a driving cavity respectively, and then the opening of the cylinder body 5 is riveted by a riveting process. A section of the steel plate at the opening is bent inward until wrapping and fastening the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com