Design method of anti-seepage drainage structure for aircraft fuselage equipment compartment

A design method and technology of anti-seepage and drainage, applied in the direction of fuselage, aircraft parts, transportation and packaging, etc., can solve the problems of aircraft crash and death, the impact of aircraft use in equipment cabins, etc., to achieve simple implementation process, simple maintenance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] A method for designing an anti-seepage drainage structure of an aircraft fuselage equipment compartment of the present invention, comprising:

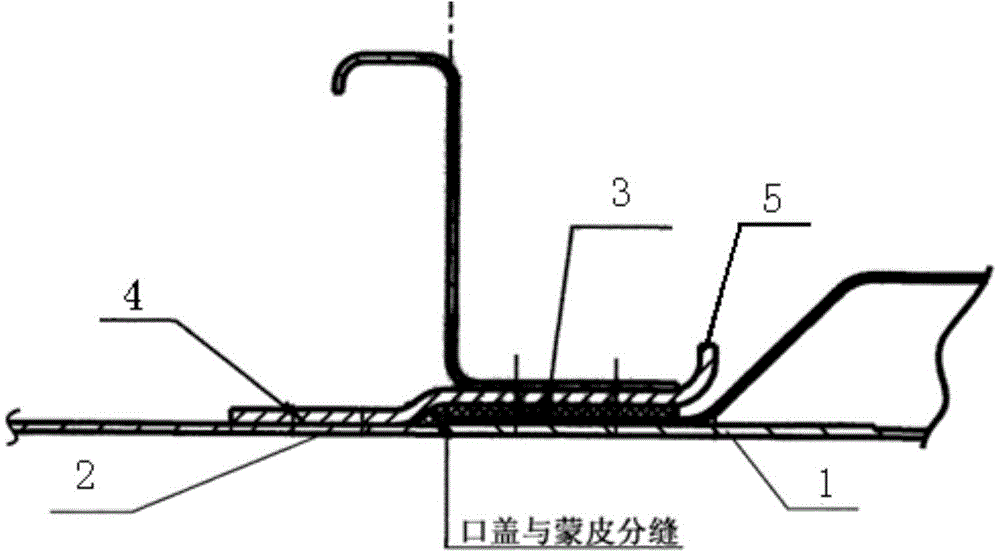

[0019] 1) The sealing design of the joint between the mouth cover 1 and the mouth frame 5:

[0020] In the overlapping area between the mouth cover 1 and the mouth frame 5, a compressible sponge rubber plate 3 is used for sealing to prevent direct leakage of rainwater; see figure 1

[0021] 2) Infiltrated rainwater drainage design:

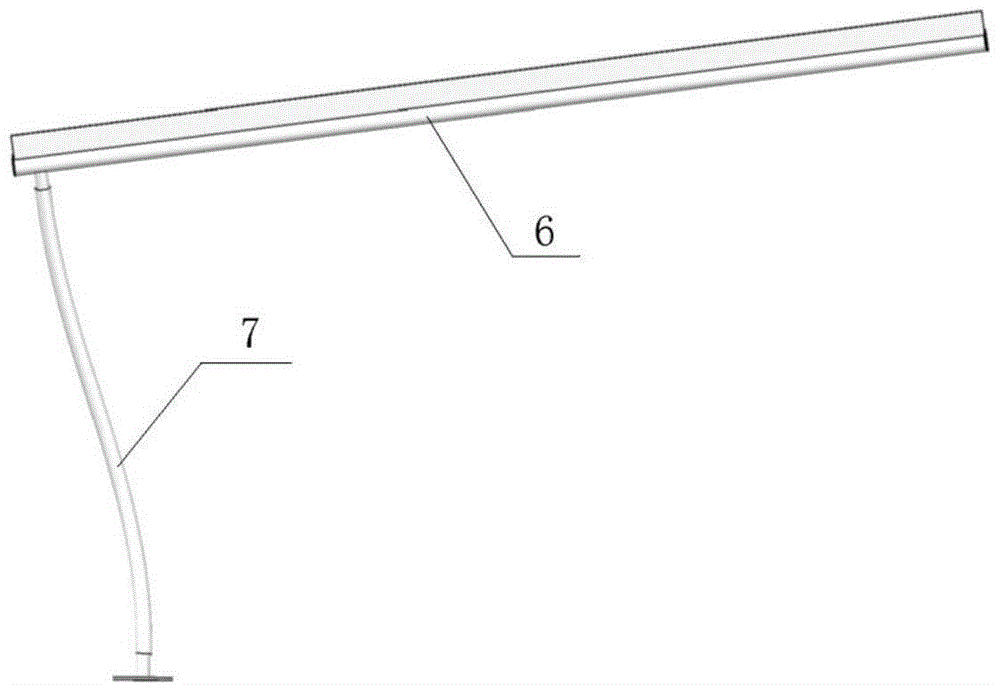

[0022] In the harsh environment of "salt fog" at sea, the dew formed on the surface of some airframes due to the temperature difference between morning and evening will slowly permeate into the interior of the side strip along the surface of the airframe in a saturated and slow permeation manner, and in the equipment hatch A diversion groove 6 with a U-shaped i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com