Pneumatic conveying system for coal ash

A technology of pneumatic conveying system and fly ash, which is applied to conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of high maintenance costs, large wear and similarities of blades and cylinders, and achieve low maintenance costs. , the effect of less maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

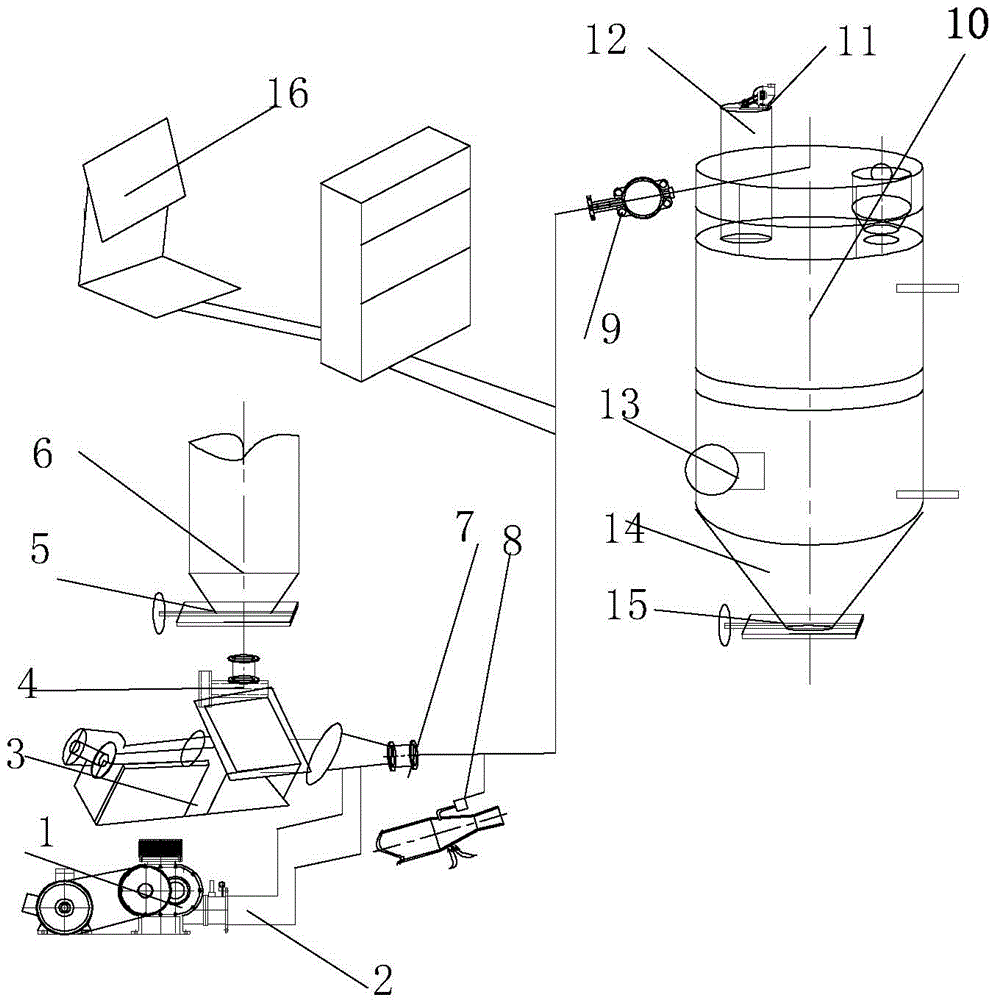

[0009] Embodiment 1 Composition and function of a pneumatic conveying system for fly ash:

[0010] The conveying system includes Roots blower 1, air duct 2, high-speed sealing belt conveyor 3, pneumatic feed valve 4, manual flapper valve 5, fly ash hopper 6, Venturi jet device 7, fly ash and air flow conveying pipe 8 , pneumatic reversing valve 9, silo 10, centrifugal induced draft fan 11, pulse blowback bag type silo dust collector 12, vibrating air hammer 13, activation hopper 14, pneumatic discharge valve 15, and electrical control system 16. It is characterized by the application of high-speed sealing belt conveyor 3 combined with Venturi jet device 7 technology to allow fly ash to enter the airflow to achieve continuous and stable transportation. It is suitable for continuous transportation, large transportation volume, short transportation distance, and pulverized coal that can be transported from one point to multiple points Gray pneumatic conveying. The Roots blower...

Embodiment 2

[0011] Embodiment 2 A kind of working process of the pneumatic conveying system of fly ash:

[0012] After the granular and powdery materials are fed by the material hopper 6, after passing through the high-speed sealing belt conveyor 3, they are drawn out from the lower outlet under the action of the air flow and the Venturi jet device 7 and sent to the material and compressed air conveying pipeline 8, according to the process and production needs The material is distributed into the bin 10 by the pneumatic switching valve 9, and the material is discharged through the pneumatic discharge valve 15. The above-mentioned related actions are all under the control of the electrical control system 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com