Saturated polyester resin wide in solubility and excellent in pigment dispersibility as well as preparation method of saturated polyester resin

A technology of pigment dispersibility and polyester resin, applied in the field of saturated polyester resin and its preparation, can solve the problems of incompatibility, low production efficiency, floating color, etc., and achieve the effect of meeting the requirements of the market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

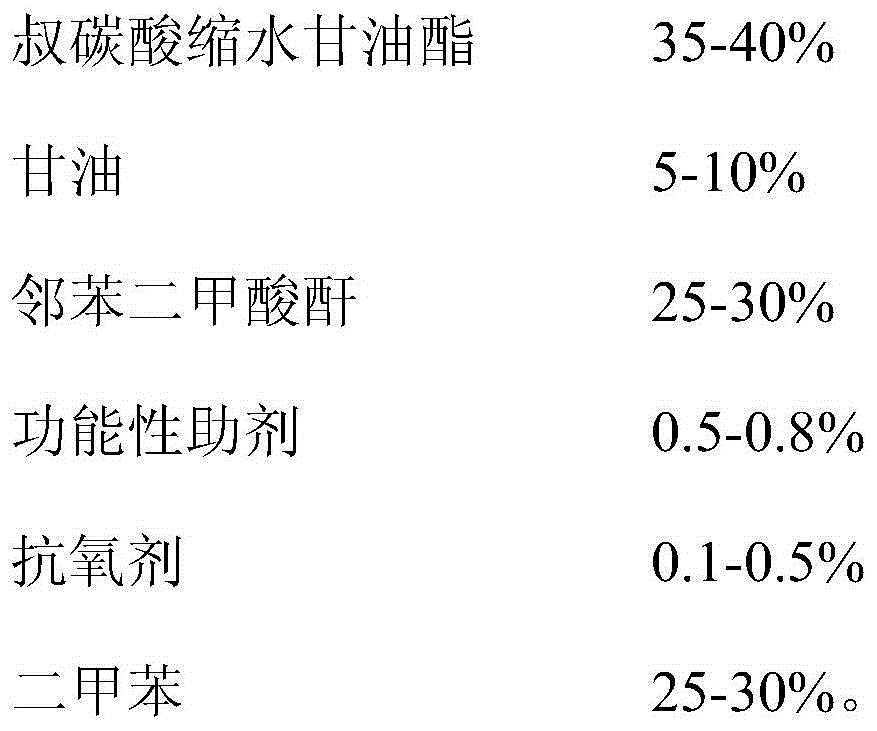

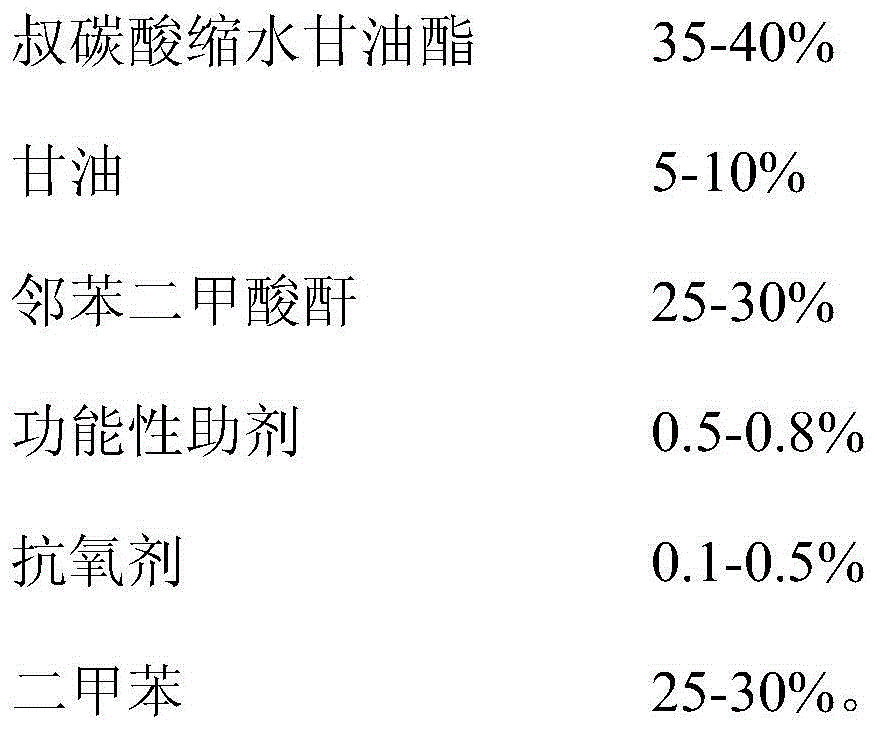

[0029] A kind of saturated polyester resin with wide compatibility and good dispersibility of pigments described in the present invention comprises the following components: by weight percentage: glycidyl tertiary carbonic acid ester 38%, glycerin, 8%, phthalic anhydride 26%, OMG The company's 0451 dispersant is 0.6%, M070 hypophosphorous acid is 0.3%, and xylene is 27.1%.

[0030] A preparation method of a saturated polyester resin with wide compatibility and good pigment dispersibility,

[0031] 1) Prepare material A, material B and material C

[0032] According to weight percentage, material A is mixed with 15-20% glycidyl tertiary carbonate, 5-10% glycerin, 15-20% phthalic anhydride, 0.1-0.5% antioxidant and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com