Biomass horizontal pyrolysis gasifier

A technology for cracking gasification and biomass, which is applied in the field of biomass energy equipment, and can solve problems such as lowering the temperature in high temperature areas, easy deformation, and unstable material layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

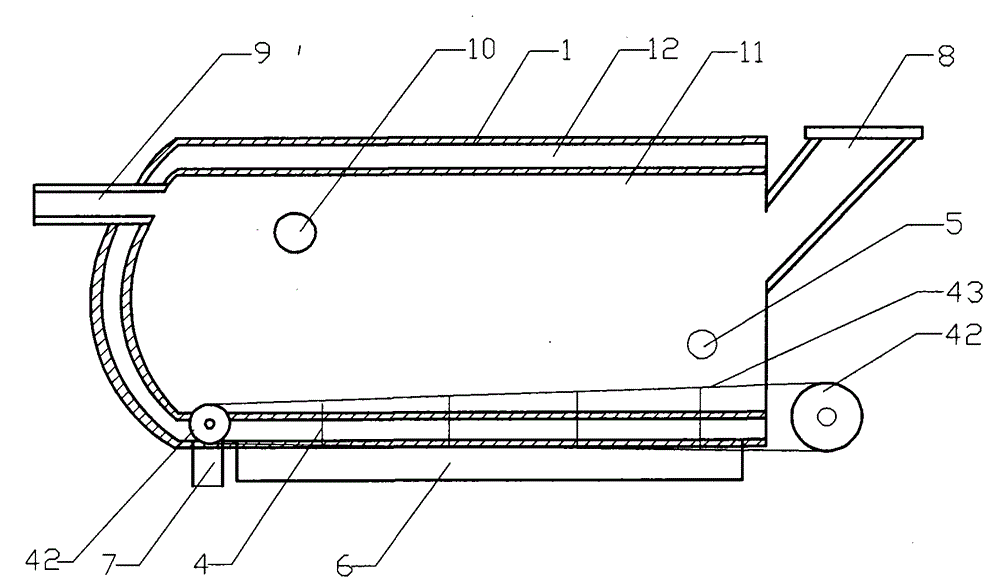

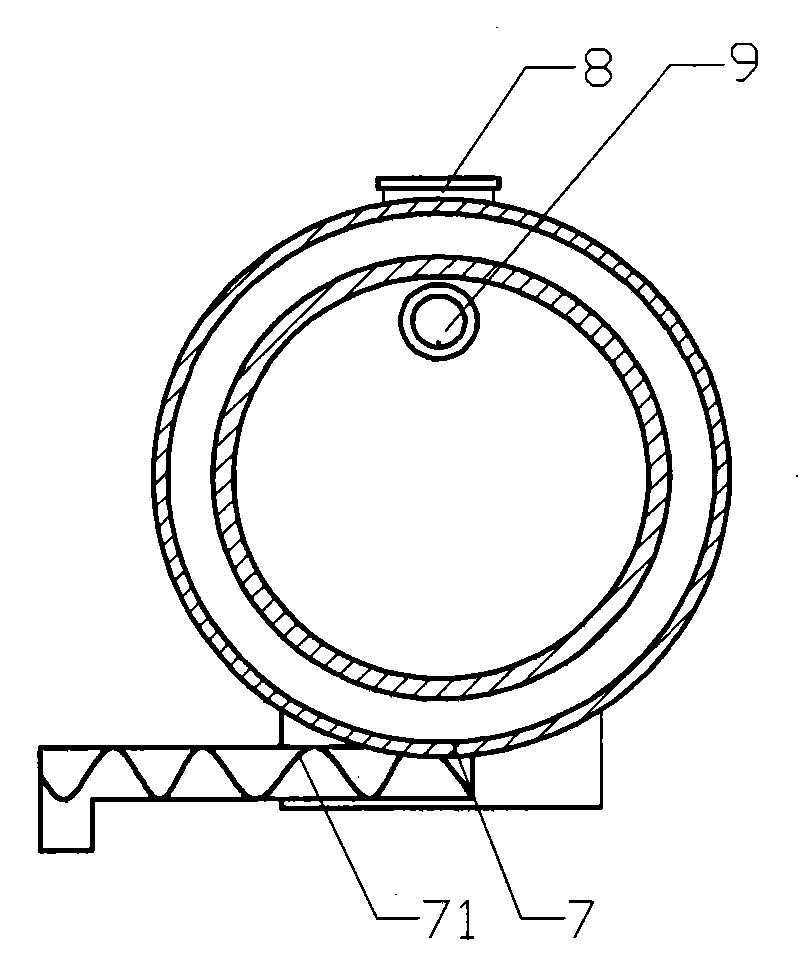

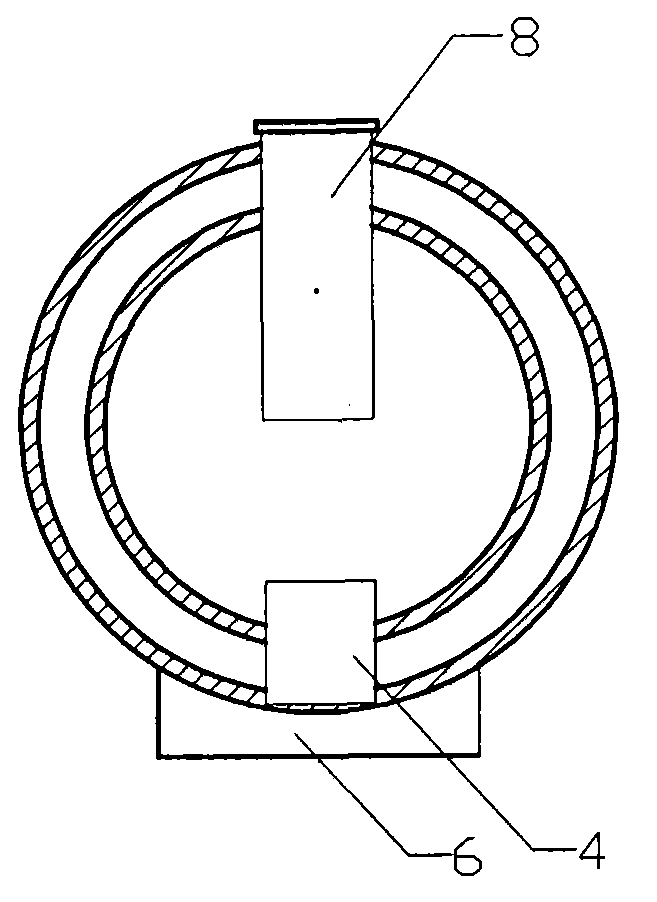

[0015] Such as figure 1 As shown, the biomass horizontal pyrolysis gasifier of the present invention has a structure comprising a horizontal furnace body 1, the left side is the front end of the furnace body, the right side is the rear end of the furnace body, the furnace body is a sandwich structure, and the interlayer inner cavity is a gasification chamber 11. In the middle of the interlayer is the air inlet chamber 12, the gas nozzle 9 is set at the front end of the furnace body, the feed port 8 is set at the rear end of the furnace body, the feed port and the gas nozzle are connected with the gasification chamber 11, and the side wall of the furnace body is opened The air inlet 5 communicates with the air inlet chamber 12 .

[0016] A feeding mechanism 4 is installed at the bottom of the furnace body, and its structure mainly includes guide wheel sets 41, 42 and recipr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com