Redundant air adjusting system

A wind system and redundant technology, applied in the field of automatic control of metallurgical blast furnace smelting, can solve the problems that cannot completely eliminate blast furnace wind failure accidents, affect the smooth progress of production, and complicated connections, etc., to achieve convenient increase and decrease configuration, increase reliability, The effect of reducing the connection relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

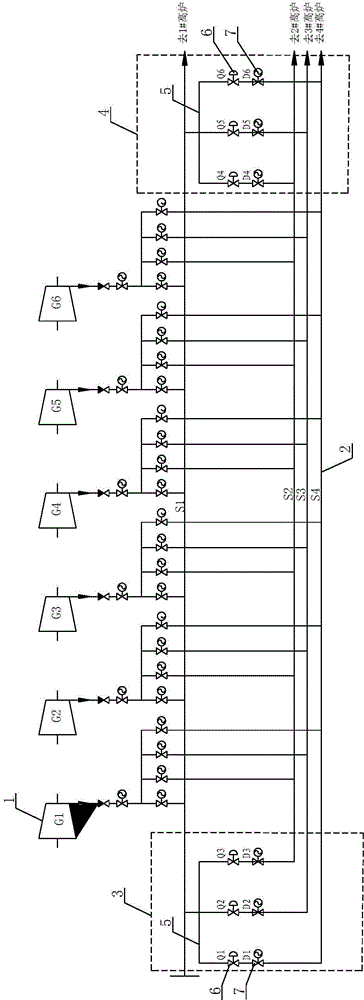

[0028] Such as figure 1 As shown, this embodiment includes 6 air blowers 1 from G1 to G6, which are respectively connected to 4 blast furnaces through 4 air supply main pipes 2 from S1 to S4. There are electric cut-off valves respectively.

[0029] The main blowing system 3 and the standby blowing system 4 use three blowing main pipes 5 to communicate with S1-S4, wherein S1 and S3-S4 are directly connected, and the connecting section of the blowing main pipe 5 is provided with a Pneumatic quick-opening valve 6 and an electric cut-off valve 7 are all connected indirectly between S2 and S3, between S2 and S4 and between S3 and S4. In the air supply system with only one blowing system, in order to ensure the communication between each blowing main pipe 5 and the air supplying main pipe 2, only the straight way. However, after adopting the redundant configuration of the blower system, the air blower pipe 5 and the air supply pipe 2 of each road can also be connected by an indir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com