An automatic ear-bending and ear-feeding mechanism for nickel starting plate seed plate

A technology of starting pole piece and seed plate, which is applied in the field of automatic ear-bending ear feeding mechanism for nickel starting pole piece seed plate, can solve the problems of large error, low work efficiency, high labor intensity of ear feeding workers, etc., and achieves defective rate. Low, reduce man-made damage, safe and reliable work operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

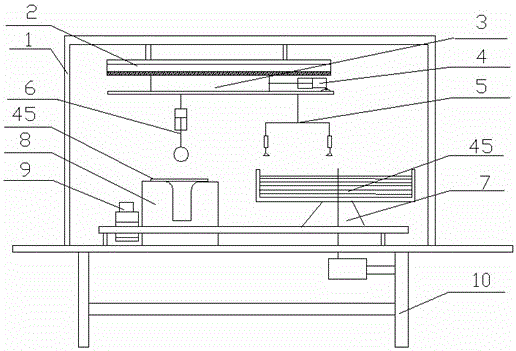

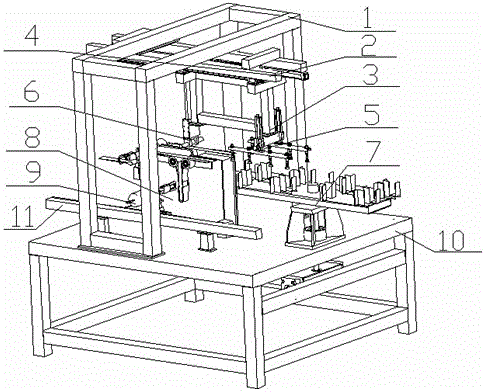

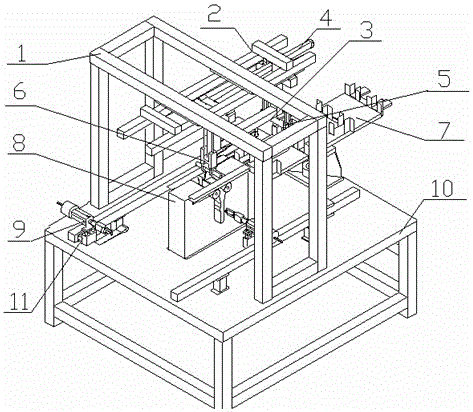

[0043] Embodiment 1: as Figure 1-20 As shown in the figure, an automatic ear-bending and ear-feeding mechanism for a nickel starting plate seed plate includes a door frame 1, a guide rail assembly 2, a trolley assembly 3, a linear guide cylinder assembly 4, a suction cup assembly 5, an air hammer assembly 6, and ear piece storage Frame assembly 7, ear piece processing component assembly 8, pneumatic swing manipulator assembly 9, underframe 10, manipulator slide rail assembly 11; underframe 10 is placed on the ground, door frame 1 is installed on the underframe 10, guide rail assembly 2 is installed on The upper part of the door frame 1, the trolley assembly 3 is installed on the lower part of the guide rail assembly 2, the linear guide cylinder assembly 4 is connected with the guide rail assembly 2 and the trolley assembly 3, the suction cup assembly 5 is installed on the lower part of the trolley assembly 3, and the pneumatic hammer assembly 6 is installed on the trolley asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com