Condensed water drainage structure for clothes dryer and clothes dryer

A technology for condensing water and clothes dryer, applied in the field of clothes dryer, can solve the problems of corroding the air inlet duct and the heat insulation shield, affecting the service life of the clothes dryer, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

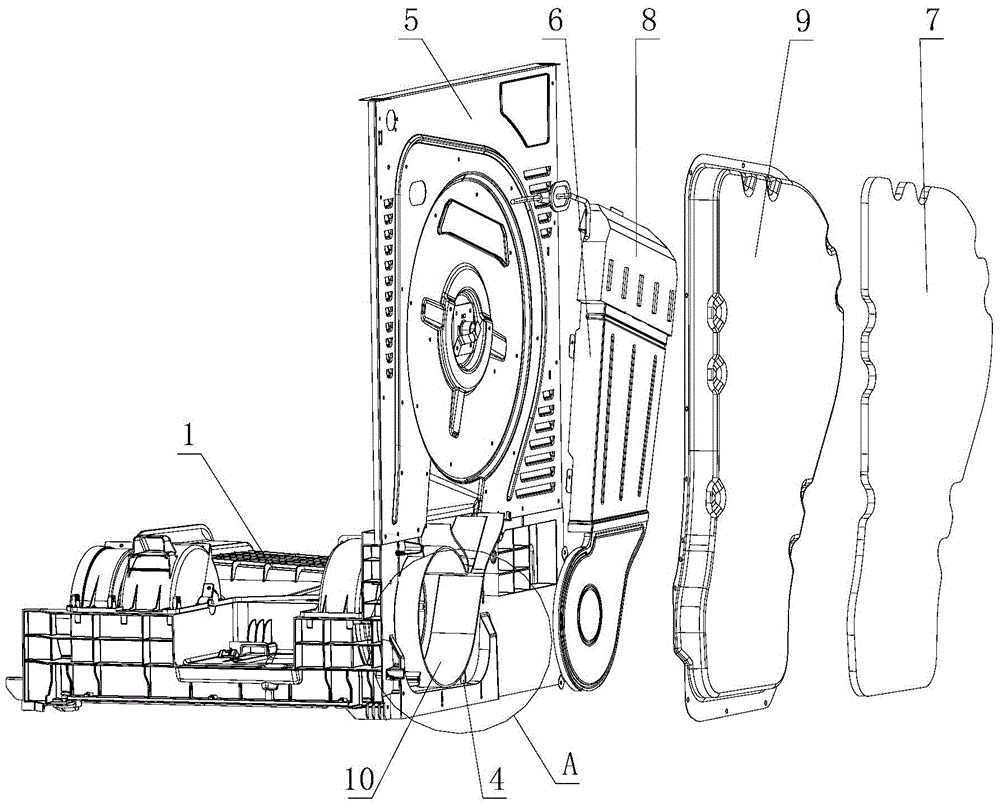

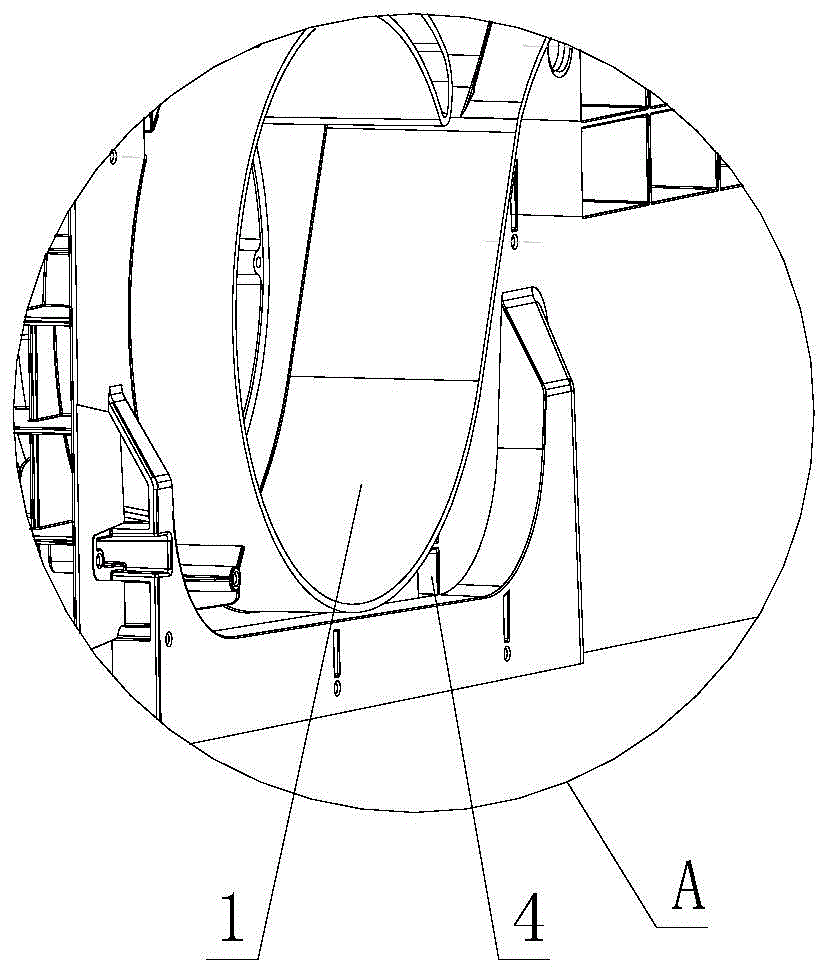

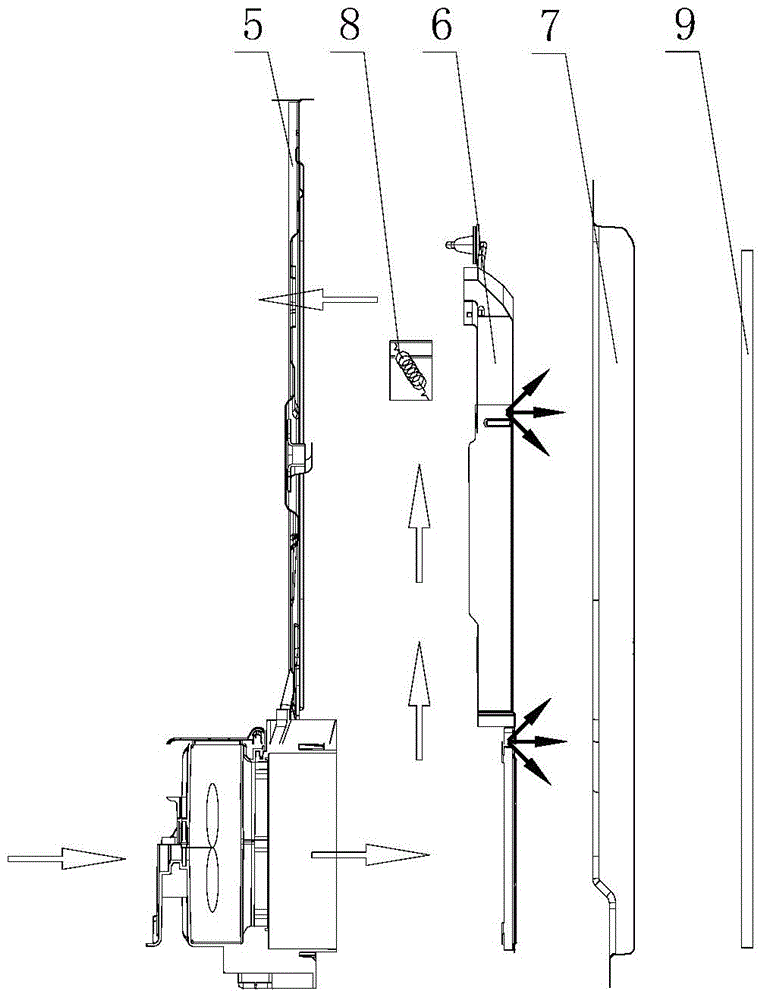

[0028] The condensed water drainage structure of a clothes dryer according to the present invention, wherein the clothes dryer includes a base 1, a shell, a condensation structure and a heating structure, a water storage tank 2 is provided below the condensation structure on the base 1, and the base 1 A condensed water drainage structure is also provided on the top, and the condensed water drainage structure communicates with the water storage tank 2 and the air inlet channel or the heat insulation area of the air inlet channel at the rear of the housing. It can make the condensed water in the air inlet duct or the heat insulation area of the air inlet duct return to the water storage tank of the base, so as to prevent the cooling water from accumulating at the bottom of the air inlet duct for a long time, corrode the air inlet duct and the heat insulation shield of the air intake duct, and affect the The service life of the whole machine.

[0029] The condensed water drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com