Full-degradable skin-care high-softness fine-denier cellulose spunlace wet tissue material and production method for wet tissue

A fully degradable, cellulose technology, used in synthetic cellulose fibers, household appliances, etc., can solve the problems of many concave and convex gaps, difficult to comb, lack of fineness and softness, etc., to achieve fine density, compactness, softness, and good skin-friendly. , The effect of improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

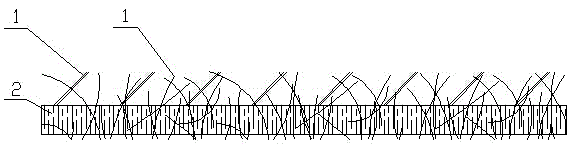

[0015] Embodiment 1: with reference to attached figure 1 . A fully degradable skin-friendly, high-soft and fine-denier cellulose spunlace wet tissue material, composed of 5-15mm cellulose fibers with a ratio of 10-80% and a fineness of less than or equal to 0.9 decitex 1 and a ratio of 90-20% after refining and separating the silk broom It is made by mixing 2 melted wood pulps. The fineness is less than or equal to 0.9 decitex 5-15mm cellulose fiber 1 and 90-20% wood pulp that has been refined and divided into silk brooms 2 mutual disordered hydroentanglement structure to form a fully degradable skin-friendly high-soft fine-denier cellulose hydroentanglement wet towel material. The 5-15mm cellulose fiber 1 with a fineness less than or equal to 0.9 dtex refers to viscose fiber and flat viscose. The surface of fully degradable soft and fine denier cellulose spunlace wet wipes is rich in -OH groups and sawtooth structure.

Embodiment 1-1

[0016] Example 1-1: On the basis of Example 1, a fully degradable soft and fine denier cellulose spunlace wet tissue material is composed of 5-15mm cellulose fiber 1 with a ratio of 10% fineness less than or equal to 0.9 decitex and 90% of the ratio is made by mixing wood pulp 2 that has been refined and segregated. The fineness is less than or equal to 0.9 decitex 5-15mm cellulose fiber 1 and 90% wood pulp that has been refined and divided into silk brooms 2 mutual disordered spunlace entanglement structure to form a fully degradable skin-friendly high-soft and fine-denier cellulose spunlace wet tissue material .

Embodiment 1-2

[0017] Example 1-2: On the basis of Example 1, a fully degradable soft and fine denier cellulose spunlace wet tissue material is composed of 5-15mm cellulose fiber 1 with a proportion of 80% fineness less than or equal to 0.9 decitex and The 20% ratio is made by mixing wood pulp that has been refined and separated. The fineness is less than or equal to 0.9 decitex 5-15mm cellulose fiber 1 and 20% of the wood pulp that has been refined and divided into silk brooms 2 mutual disordered spunlace entanglement structure to form a fully degradable skin-friendly high-soft and fine-denier cellulose spunlace wet tissue material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Blade thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com