Membrane frame and construction method for the construction of the ball under the turntable of the swivel bridge

A technology for bridges and turntables, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inconvenient disassembly, easy deformation of formwork supports, low stability, etc., and achieves convenient disassembly, low construction cost, and good self-compacting properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] specific implementation

[0033] The structural features of the present invention will now be described in detail in conjunction with the accompanying drawings.

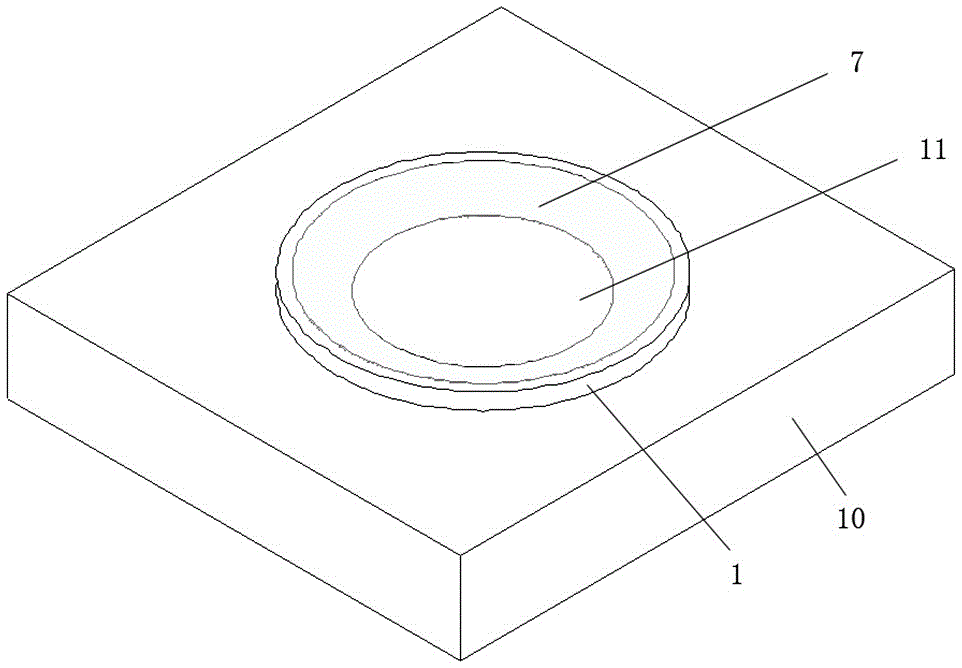

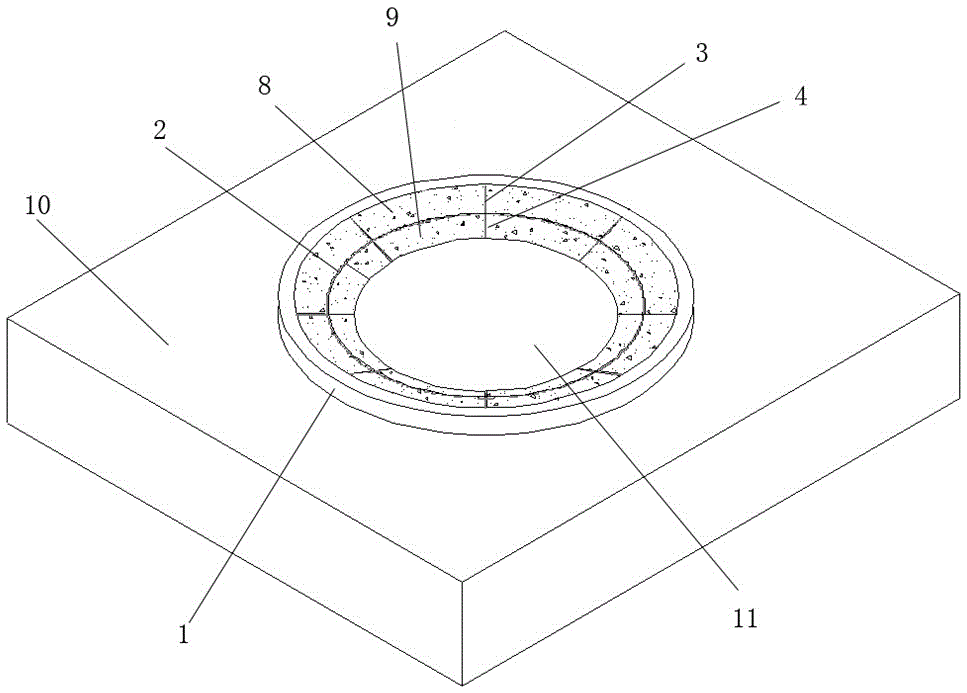

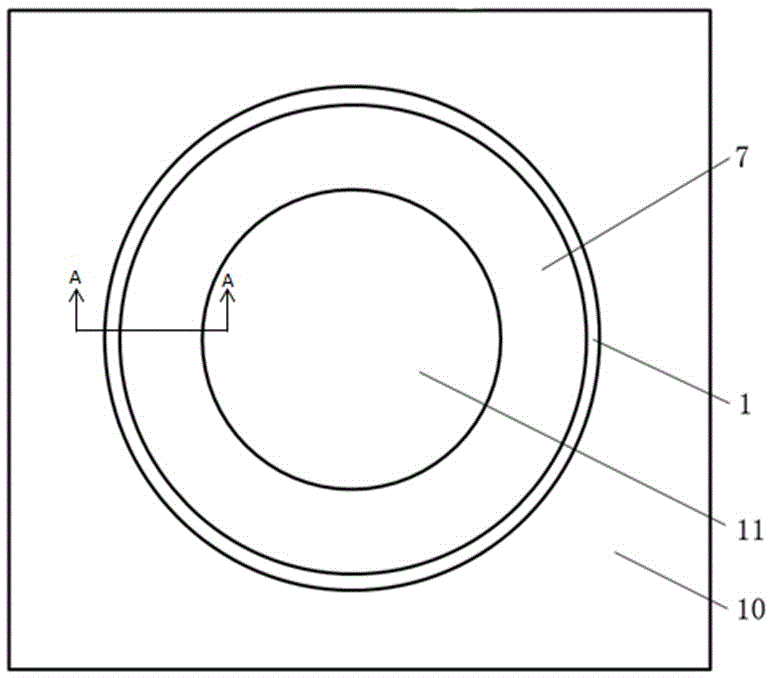

[0034] see figure 1 , the film frame used for the construction of the ball under the turntable of the swivel bridge consists of a main ring body 1, a quasi-ring body 2, a first support body 3, a second support body 4, a bottom cushion layer 5, and a top first The cover layer 6, the top second cover layer 7, the first filling part 8 and the second filling part 9 constitute, such as figure 2 and Figure 5 shown; wherein, the main ring body 1 is a hollow tube with a diameter not exceeding 6m, see figure 2 ; The inner side of the main annular body 1 is provided with a bottom cushion layer 5; the bottom cushion layer 5 is not a ring-shaped sheet.

[0035] see Figure 5 , the quasi-circular body 2 is provided with the quasi-circular body 2 on the inner bottom cushion layer 5 of the main circular body 1; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com