Tower pole concrete precasting base

A technology of concrete prefabricated parts and prefabricated components, which is applied in the direction of towers, building types, buildings, etc., can solve the problems of difficult foundation construction, long construction period, and long delay of base station construction period, so as to reduce disturbance to residents, improve production efficiency, The effect of reducing on-site work processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below through specific examples.

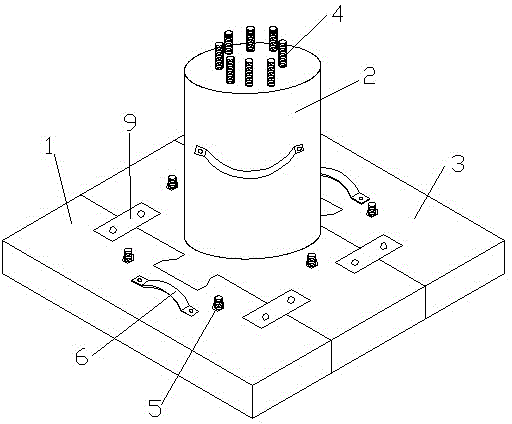

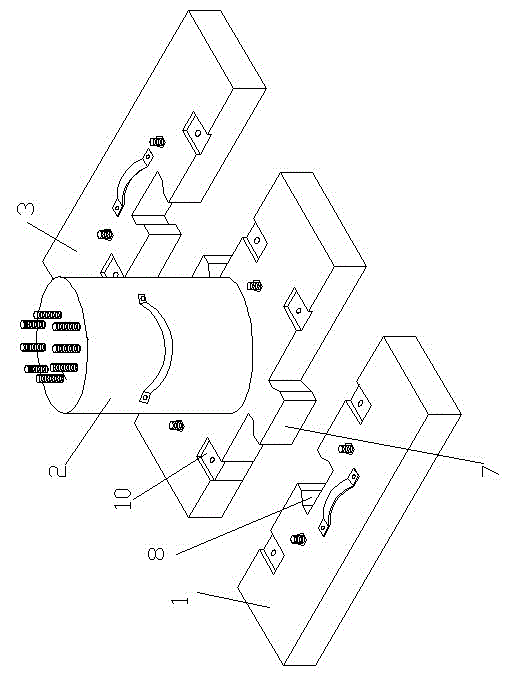

[0011] Such as figure 1 , figure 2 As shown, the tower rod concrete prefabricated base of the present invention has a left prefabricated component 1, a middle prefabricated component 2 and a right prefabricated component 3, the middle prefabricated component 2 is composed of a base and a column connected as one, the left prefabricated component 1 and the right prefabricated component The prefabricated component 3 is symmetrically connected to both sides of the middle prefabricated component 2 through a dovetail-shaped concave-convex matching structure, and the upper end surface of the middle prefabricated component 2 is embedded with anchor bolts 4 for fixedly connecting the upper rod body. The left prefabricated component 1 and the right prefabricated component The component 2 is provided with a pre-embedded anchor bolt assembly 5 for the installation of prefabricated connectors, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com