Segmented bit of long spiral drilling machine

A long auger, long helix technology, applied in the direction of drill bit, drill pipe, drill pipe, etc., to achieve the effect of facilitating smoothness, solving large pile position deviation, and ensuring pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

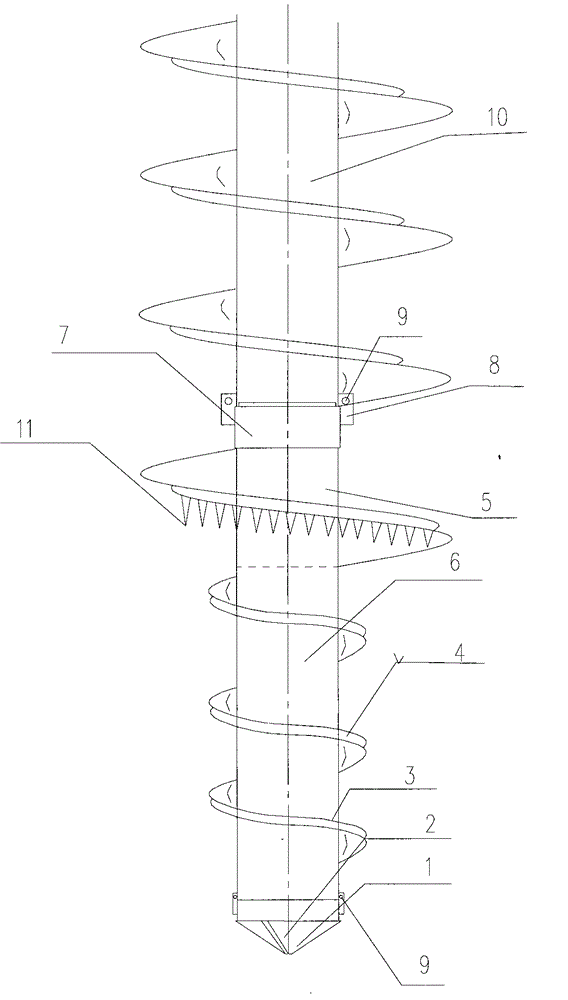

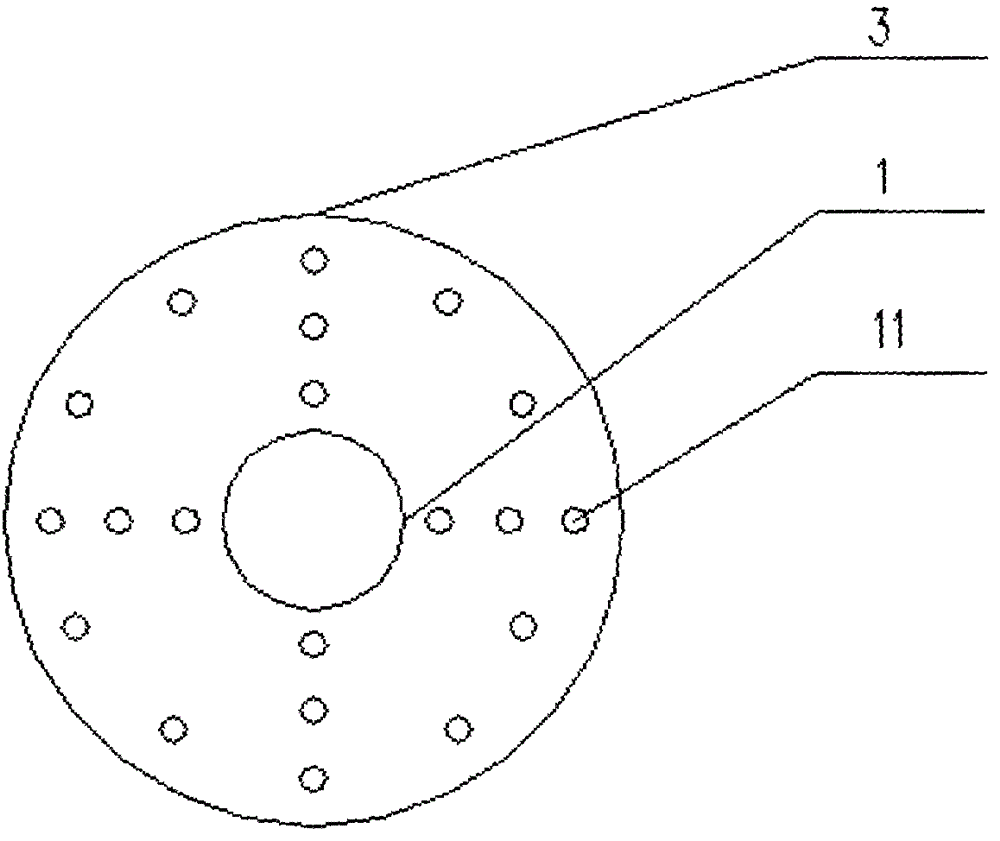

[0014] Such as figure 1 As shown, the top of the drill bit is provided with a lip-shaped locating ring 7 with an axial positioning function, and a pair of fixed ears 8 for fixed connection with the long helical drill rod 10 are provided on both sides of the lip-shaped locating ring 7, and the fixed ears 8 are provided with Fixed screw 9; drill core is divided into cutting section drill core 5 and guide section drill core 6, spiral blade 3 is set on the drill core, and the front end of spiral blade 3 has cutting edge 4; Teeth 11, the bottom end of the drill bit has a drill tip 1, and the drill tip 1 is provided with a main cutting tool 2.

[0015] After the pilot hole, align the drill bit with the prefabricated pilot hole, remove the fixing screw 9 on one side used to fix the connection between the drill bit tip 1 and the guide section drill core 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com