Fracturing tubular column dragged under pressure and fracturing method thereof

A technology of dragging and fracturing pipe strings under pressure, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., and can solve the constraints of high efficiency, low cost and high cost of horizontal well staged fracturing technology , lengthening of construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

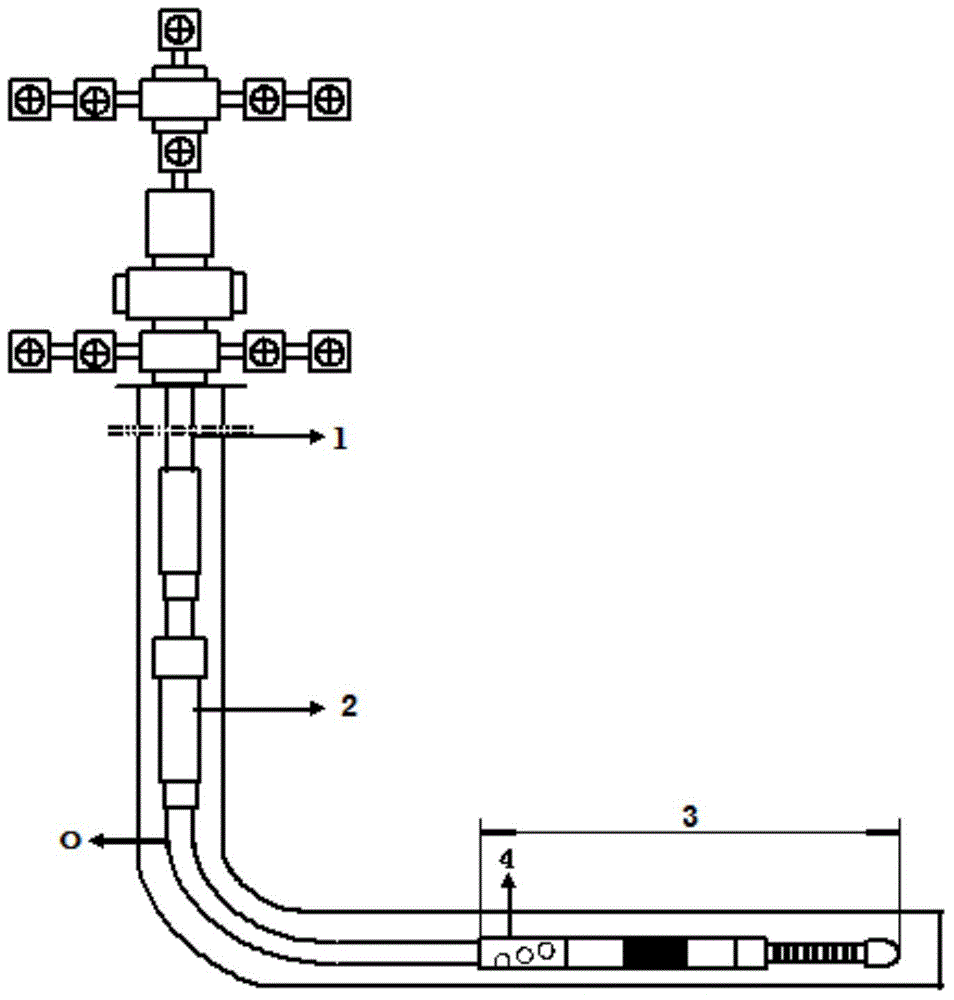

[0008] refer to figure 1 Embodiments of the present invention are further described:

[0009] The pressurized drag fracturing string is composed of a hydraulic controllable on-off valve 2 connected through a tubing 1 and a perforating fracturing string 3 with an injector 4 at the upper end.

[0010] The fracturing method of the drag fracturing string under pressure is as follows:

[0011] 1. First, run the perforating and fracturing string 3 into the well normally;

[0012] 2. According to the engineering design, install the hydraulic controllable on-off valve 2 at the position of the five oil pipes above the kickoff point O to ensure that the pipe string will not go down into the kickoff point when it moves, and then connect the oil pipe 1 to the blowout preventer Wellhead;

[0013] 3. After the surface pipeline is connected and the perforation and fracturing of the first section of the reservoir are carried out, the tubing 1 is removed, the pipeline is injected, the blowo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com