Flow diversion chamber capable of testing flow diversion capacity of fracture network of tight reservoir by gas and working method thereof

A technology of diversion capacity and tight reservoirs, applied in the field of diversion chambers, can solve the problems of high cost, neglect, and inability to simulate formation lithology, etc., and achieve the effects of saving costs, expanding the spread range, and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

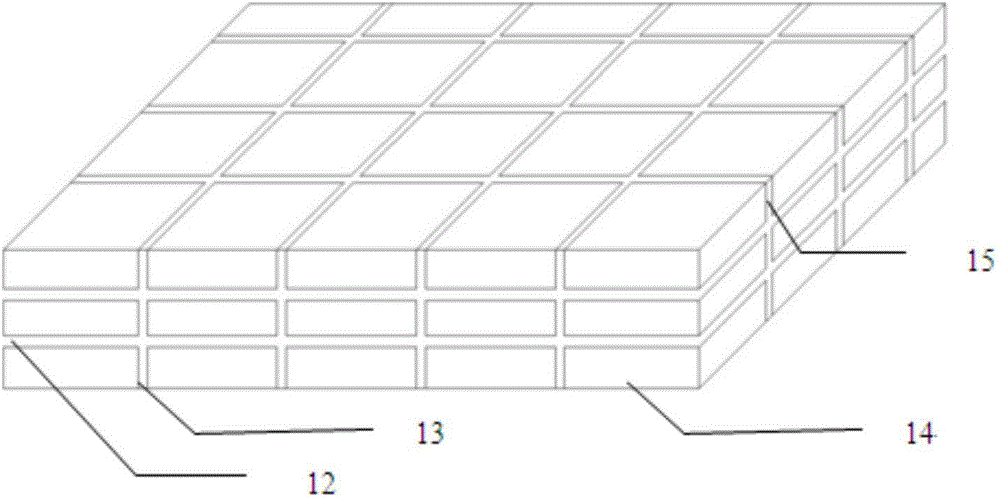

[0056] Study vertical fractures in fracture network structures such as figure 1 Influence of the number of vertical fractures 15 on the conductivity of the fracture network. Use a cutting machine to process the shale core into a plate-shaped core with the same size, with a length of 50-60 mm, a width of 50-60 mm, and a thickness of 12-15 mm; by adding proppant or not, the number of vertical fractures is controlled. Fractures are directly closed without adding proppant; the single fracture width, proppant, and sand concentration in the fracture network are the same, and a fracture network model with different numbers of vertical fractures is assembled. By measuring the conductivity of the fracture network in different models, the influence of the number of vertical fractures on the conductivity of the fracture network can be obtained.

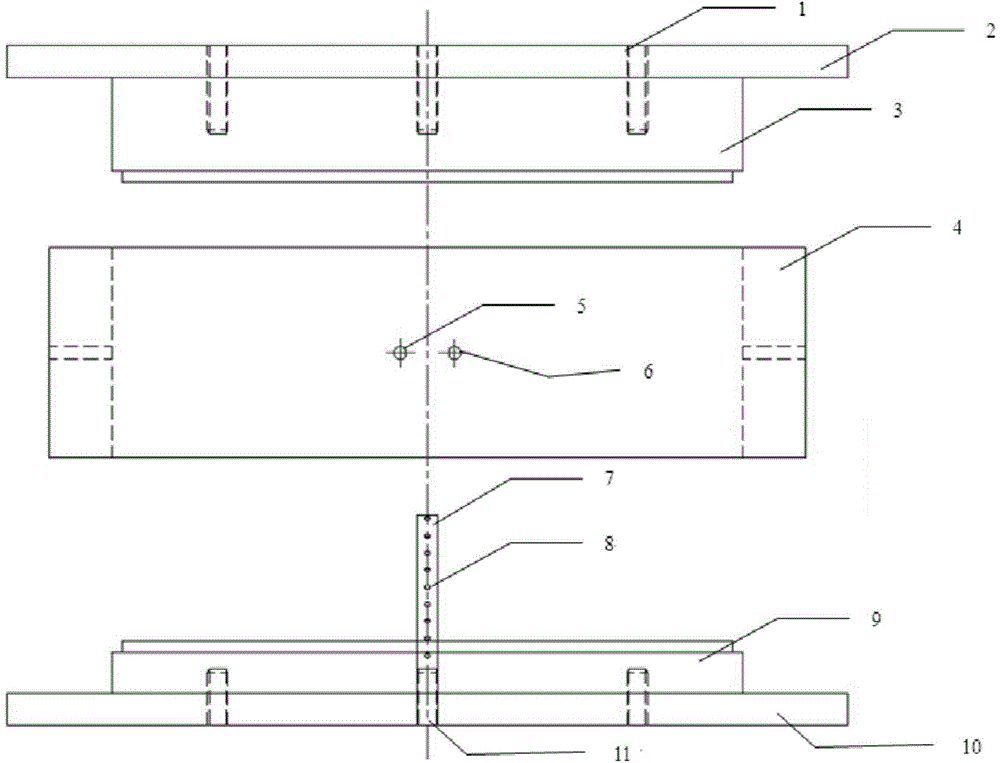

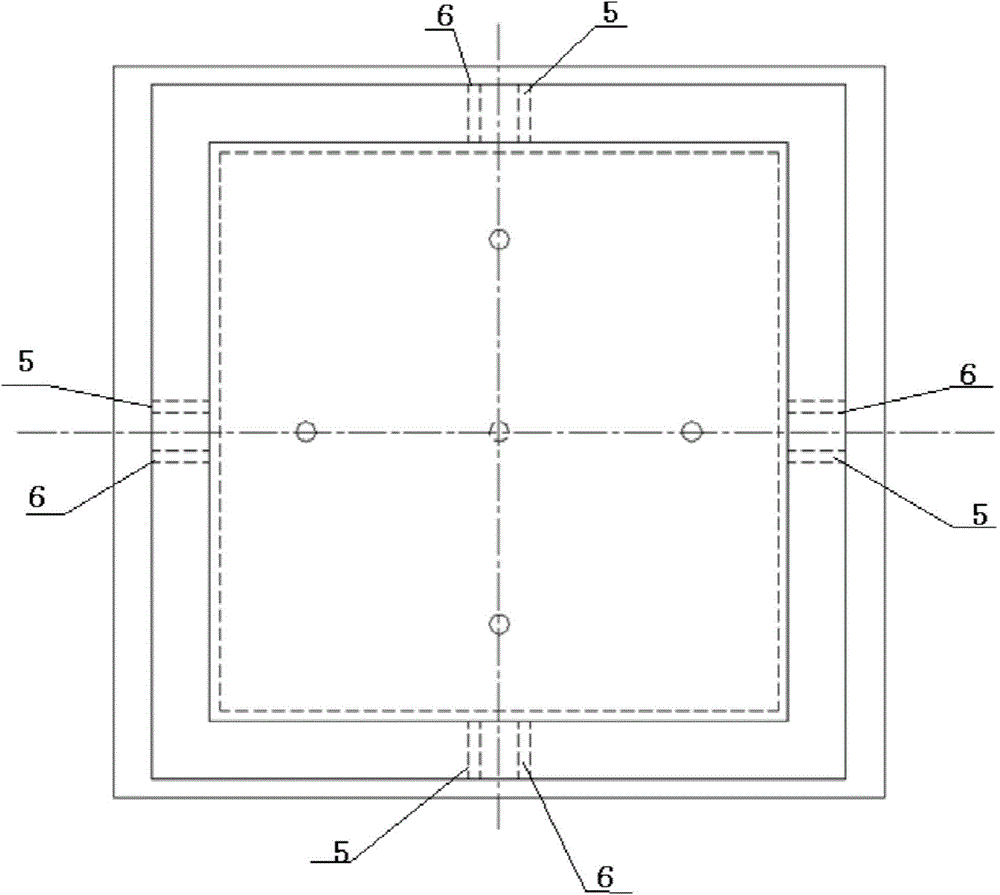

[0057] A diversion chamber for testing the diversion capacity of a tight reservoir fracture network for gas, comprising a test tank 4 arranged...

Embodiment 2

[0062] A diversion chamber for gas testing the conductivity of a fracture network in a tight reservoir as described in Example 1, the difference lies in that a simulated wellbore 7 is arranged through the center of the sealed bottom plate.

[0063] The thickness of the sealing top plate and the sealing bottom plate are both 10-15 mm; the thickness of the upper sealing plug is 40-50 mm; the thickness of the lower sealing plug is 20-25 mm.

[0064] A sealing groove is provided on the surface of the upper sealing plug and the lower sealing plug, and a sealing film is provided in the sealing groove, and the thickness of the sealing film is 5-7mm.

Embodiment 3

[0066] Utilize the method for testing the flow conductivity of a tight reservoir fracture network using a flow diversion chamber as described in embodiment 1 or 2, comprising the following steps:

[0067] (1) selecting formation rocks, i.e. shale or tight sandstone, and processing the formation rocks into slab cores;

[0068] (2) According to the preset fracture network structure, the slab core is cut horizontally and vertically into different small sections, and put into the test groove;

[0069] (3) Construct the number of fractures and the fracture network structure by adding proppant: that is, control the fracture width of the fracture network by adding proppant with different particle sizes or using different sanding concentrations;

[0070] (4) Install the diversion chamber, and connect the four air inlets with the air inlet of the API diversion capacity tester;

[0071] (5) Open the data acquisition and control system of the API diversion tester, pressurize the diversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com