Method for charging implemented by using curvy auxiliary rocker arm of mining machine and curvy auxiliary rocker arm-charging mining machine for implementing method

A secondary rocker arm and charging technology, which is applied in the mechanical field, can solve the problems of poor charging effect, reduced time utilization efficiency, and increased waste of excavated materials in impact harvesters, so as to reduce resistance, reduce wear, and prevent crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

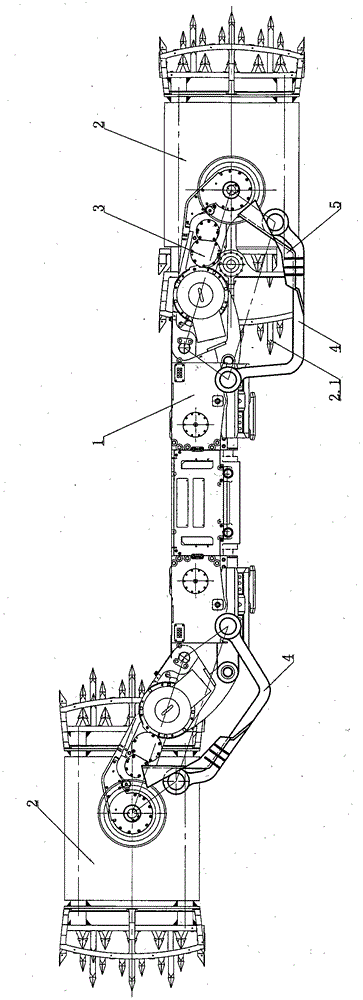

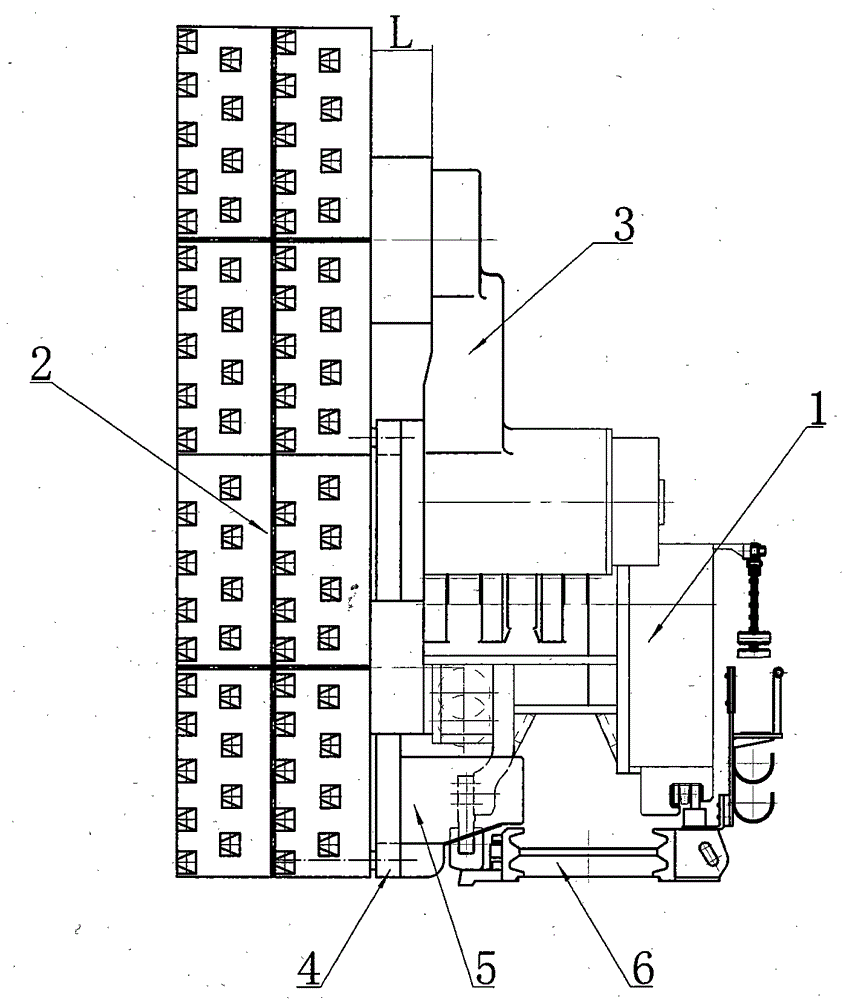

[0049] Such as Figure 1 to Figure 2 As shown, a kind of curved auxiliary rocker arm charging material mining machine that realizes the method for charging the curved auxiliary rocker arm of the material harvester includes a reciprocating impact power box 2, a main rocker arm 3, a curved auxiliary rocker arm 4, and an auxiliary rocker arm. Rocker loading part 5, fuselage 10 and running part 1, etc., one end of main rocker arm 3 is hinged with reciprocating impact power box 2, etc., the other end is hinged with fuselage 10, etc., one end of curved auxiliary rocker arm 4 is connected with reciprocating impact power box 2, etc. The box 2 is hinged, and the other end is hinged with the lower end of the side part of the fuselage 10. The connection line between the two hinge points of the main rocker arm 3 and the two hinge points of the curved auxiliary rocker arm 4 are parallel and equal in length, and the reciprocating impact power box 2 , the main rocker arm 3, the curved auxili...

Embodiment 2

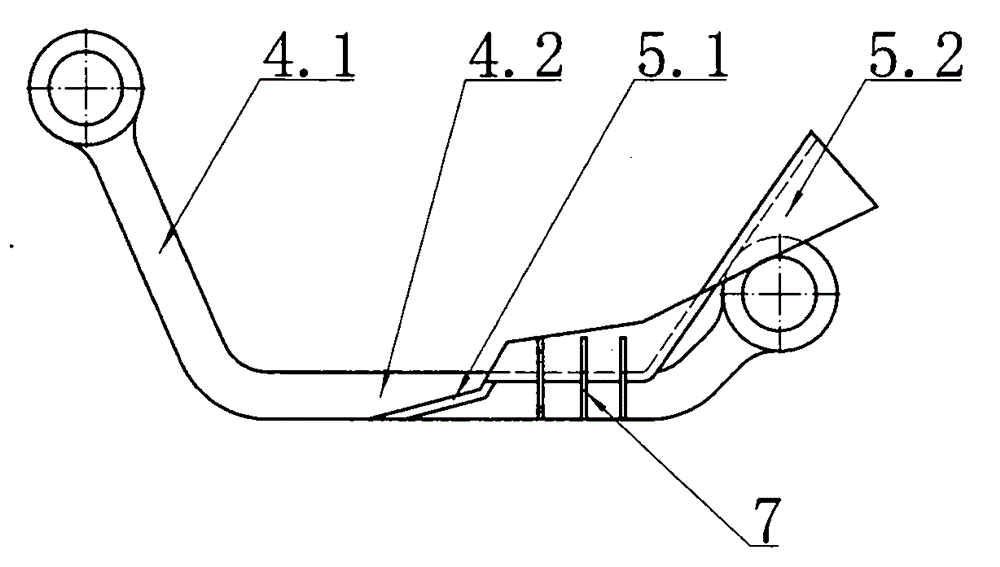

[0052] Such as Figure 3 to Figure 6 As shown, the auxiliary rocker arm loading part 5 includes a shovel plate 5.1 and a baffle plate 5.2, etc., the shovel plate 5.1 is arranged on the lower curved section where the cleaning material support box section 4.2 falls on the ground, and the cleaning material support box The lower curved section of the body section 4.2 falling on the ground is equal to or lower than the height of the conveyor 6, so as to prevent the cleaning material from supporting the lower curved section of the box body section 4.2 falling on the ground, and the material blocking plate 5.2 is close to The hinged part of the supporting box section 4.2 of the clearing material is set to the hinged part of the reciprocating impact power box 2. The height of the baffle plate 5.2 is higher than the height of the conveyor 6, and the material baffle plate 5.2 scoops up the shovel plate 5.1 Push into conveyor 6.

[0053] The baffle 5.2 includes a bottom baffle 5.2.1 and...

Embodiment 3

[0065] Such as Figure 7 to Figure 9 As shown, a kind of curved auxiliary rocker arm charging material mining machine that realizes the method for charging the curved auxiliary rocker arm of the material harvester includes a reciprocating impact power box 2, a main rocker arm 3, a curved auxiliary rocker arm 4, and an auxiliary rocker arm. Rocker loading part 5, fuselage 10 and running part 1, etc., one end of main rocker arm 3 is hinged with reciprocating impact power box 2, etc., the other end is hinged with fuselage 10, etc., one end of curved auxiliary rocker arm 4 is connected with reciprocating impact power box 2, etc. The box 2 is hinged, and the other end is hinged with the lower end of the side part of the fuselage 10. The connection line between the two hinge points of the main rocker arm 3 and the two hinge points of the curved auxiliary rocker arm 4 are parallel and equal in length, and the reciprocating impact power box 2 , the main rocker arm 3, the curved auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com