Sliding vane type expansion working machine

A power machine, sliding vane technology, applied in rotary piston engines, mechanical equipment, engine components, etc., can solve the problems of unbearable high temperature and low isentropic expansion efficiency, and achieve high expansion isentropic efficiency and isentropic expansion. The effect of high efficiency and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

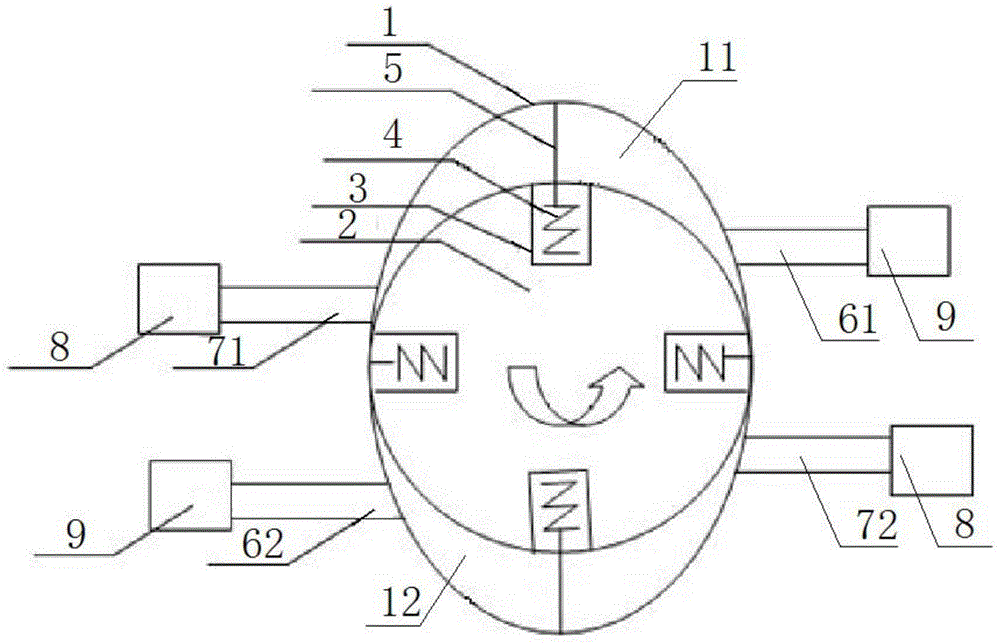

[0027] Rotate the rotating shaft 2 counterclockwise, the volume increases, and the gas enters the upper working chamber 11 from the high-temperature and high-pressure gas boundary 9 through the upper air inlet pipe 61 until the sliding plate 5 rotates to a position coincident with the long axis of the housing 1, the first air intake The stroke ends; the rotating shaft 2 continues to rotate counterclockwise, the volume decreases, and the gas is output from the upper working chamber 11 to the environment 8 through the upper exhaust pipe 71 until the sliding plate 5 rotates to a position coincident with the line where the short axis of the housing 1 is located. The sliding plate 5 is completely pressed into the card slot 3, and the first exhaust stroke ends; the rotating shaft 2 continues to rotate counterclockwise, and the volume increases, and the gas enters the lower working chamber 12 from the high-temperature and high-pressure gas boundary 9 through the lower intake pipe 62 un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com