Energy-saving type external-meshing gear pump

A gear pump, external meshing technology, used in pumps, pump components, rotary piston pumps, etc., can solve problems such as high noise, application limitations, poor flow uniformity, etc., to achieve high volumetric and mechanical efficiency, simple structure, and work. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

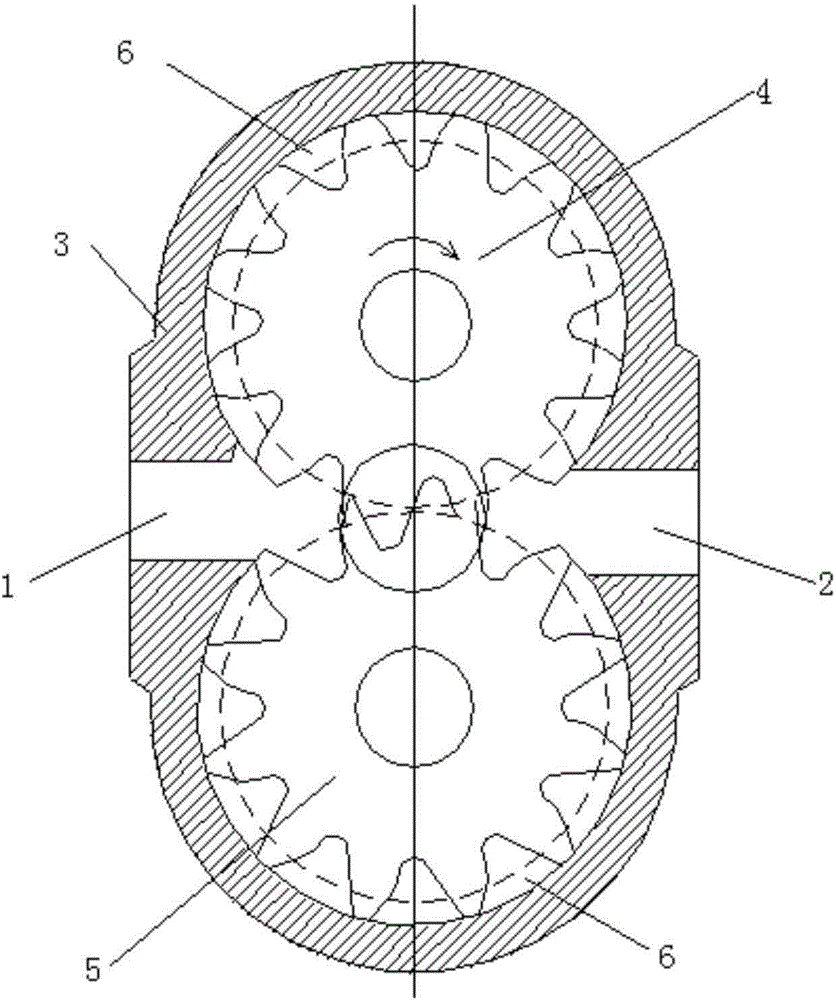

[0016] refer to figure 1 , the specific embodiment adopts the following technical scheme: it includes an oil inlet 1, an oil outlet 2, a pump body 3, a driving gear 4 and a driven gear 5, and the pump body 3 is provided with a driving gear 4 and a driven gear 5, The driving gear 4 meshes with the driven gear 5, and the two ends of the center of the pump body 3 are respectively provided with an oil inlet 1 and an oil outlet 2, and the pump body 3 is sealed by the sealing surfaces at both ends. Oil outlets 2 are provided with flow meters.

[0017] It is worth mentioning that the pump body 3 forms a sealed oil chamber 6 with each interdental groove of the driving gear 4 and the driven gear 5 .

[0018] Moreover, the gear pump uses a DC brushless mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com