An open water pump and its application

An open type, water pump technology, applied in the field of water pumps, can solve the problems of increasing the power consumption of the water pump, reducing the water drawing efficiency of the water pump, affecting the cleaning effect of the washing machine, etc., to improve the water drawing efficiency, convenient disassembly and manufacture, and improve the balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

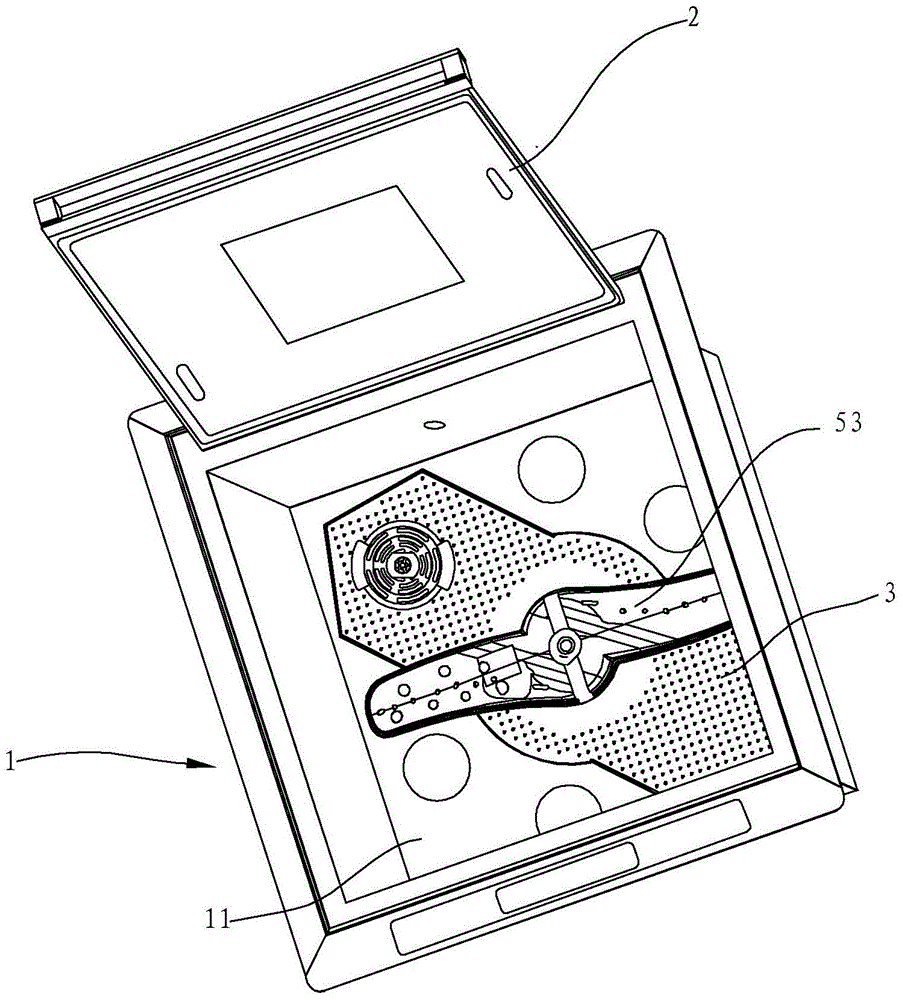

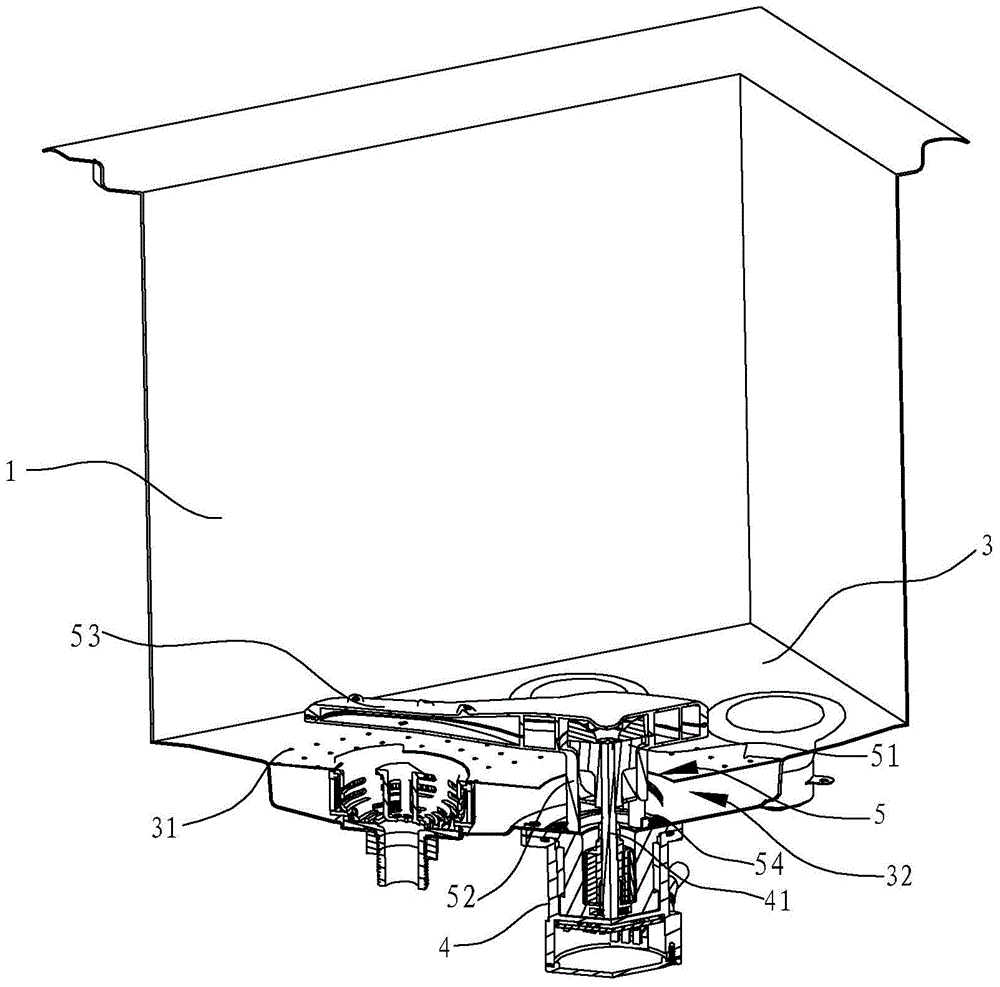

[0025] see Figure 1 ~ Figure 4 , a sink type washing machine, can be used for washing dishes, vegetables, fruits, etc., comprising a sink body 1, and a cover plate 2 rotatably connected to the top of the sink body 1, the sink body 1 can be an ordinary household sink, sink The main body 1 and the cover plate 2 form a washing space for accommodating and washing the above-mentioned dishes, vegetables, fruits and the like.

[0026] The bottom plate 11 of the sink body 1 is concave at least in the central part, and above the concave part of the bottom plate 11, there are drain plates 3 having the same shape as the concave part at intervals, and a plurality of drain plates 3 are provided on the drain plate 3 for draining water. The hole 31 , the space between the drain plate 3 and the concave part of the bottom plate 11 forms a drain area 32 , and the drain plate 3 is flush with other parts of the bottom plate 11 . The outside of the tank body 1, the bottom of the base plate 11 is...

Embodiment 2

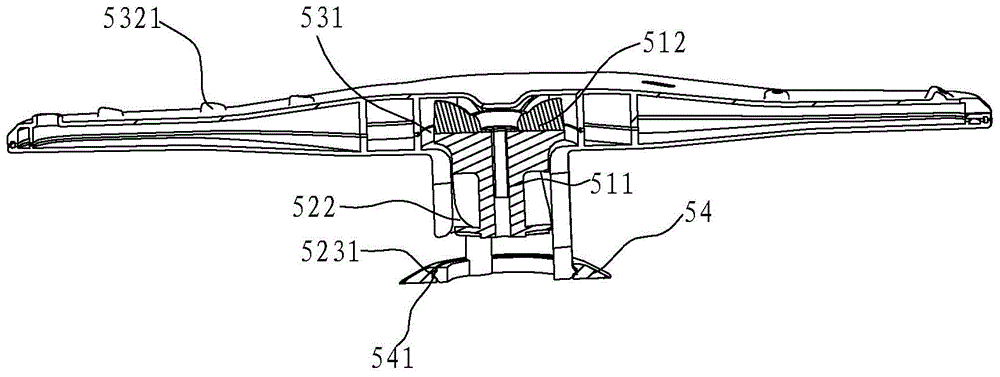

[0036] see Figure 5 and Figure 6 , in this embodiment, the difference from the first embodiment above is that the lower cover body 533 of the rotating spray arm 53 is detachably connected to the guide bracket 52, such as through threaded connection, such as the top outer periphery of the guide bracket 52 An external thread 524 is provided, and an internal thread 5331 is provided at a corresponding position on the lower cover body 533 of the rotating spray arm 53, so that the rotating spray arm 53 can rotate synchronously with the guide bracket 52, and the installation, disassembly and manufacture are all very easy. convenient. If the direction of rotation of the rotating spray arm 53 is clockwise (viewed from the top of the tank body 1), right-handed threaded connection is used; Threaded connection, thus can prevent loosening between the rotating spray arm 53 and the guide bracket 52 .

[0037] The lower cover body 533 of the rotating spray arm 53 and the guide bracket 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com