Inverted front shock absorber

A front shock absorber and a part of the technology, applied in the field of inverted front shock absorbers, can solve the problems of being difficult to apply to ordinary motorcycles with small and medium displacements, not being widely used, and difficult to break through in key technologies, and achieving lower surface quality requirements, The effect of improving the life and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

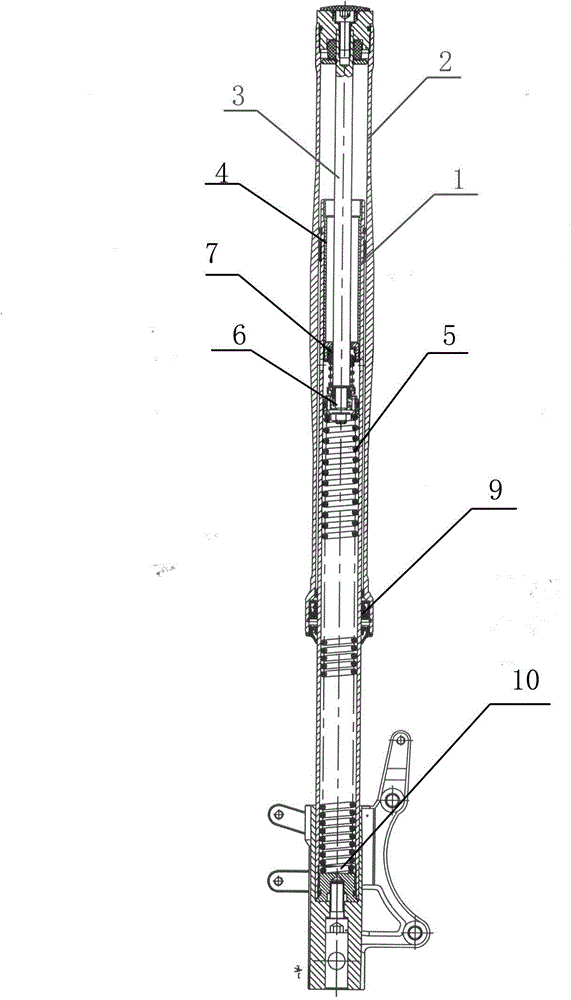

[0008] exist figure 1 Among them, the present invention provides an inverted front shock absorber, which includes a handle tube 1, a shock absorbing sleeve 2 and a piston rod 3, a part of the handle tube 1 is inserted into the shock absorbing sleeve 2, and the inner cavity of the handle tube 1 Set as a working chamber, a part of the piston rod 3 is inserted into the working chamber of the handle tube 1 through the inlet side of the handle tube 1, and a damping tube 4 is arranged in the handle tube 1, and a part of the piston rod 3 is located outside the handle tube 1, The other part of the piston rod 3 is inserted into the damping tube provided in the handle tube 1, one end of the piston rod 3 is located outside the handle tube 1, one end of the piston rod 3 is connected to one end of the shock absorbing sleeve 2, and the other end of the piston rod 3 extends After entering the damping tube 4, the damping tube 4 is stretched out to be opposite to the damping spring 5 provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com