A kind of rapid corrosion method of weathering steel plate

A steel plate, fast technology, applied in the direction of metal material coating process, etc., can solve the problems of non-environmental protection, high material surface quality requirements, immature processing technology, etc., and achieve the effect of easy operation, simple equipment, and simple and easy implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

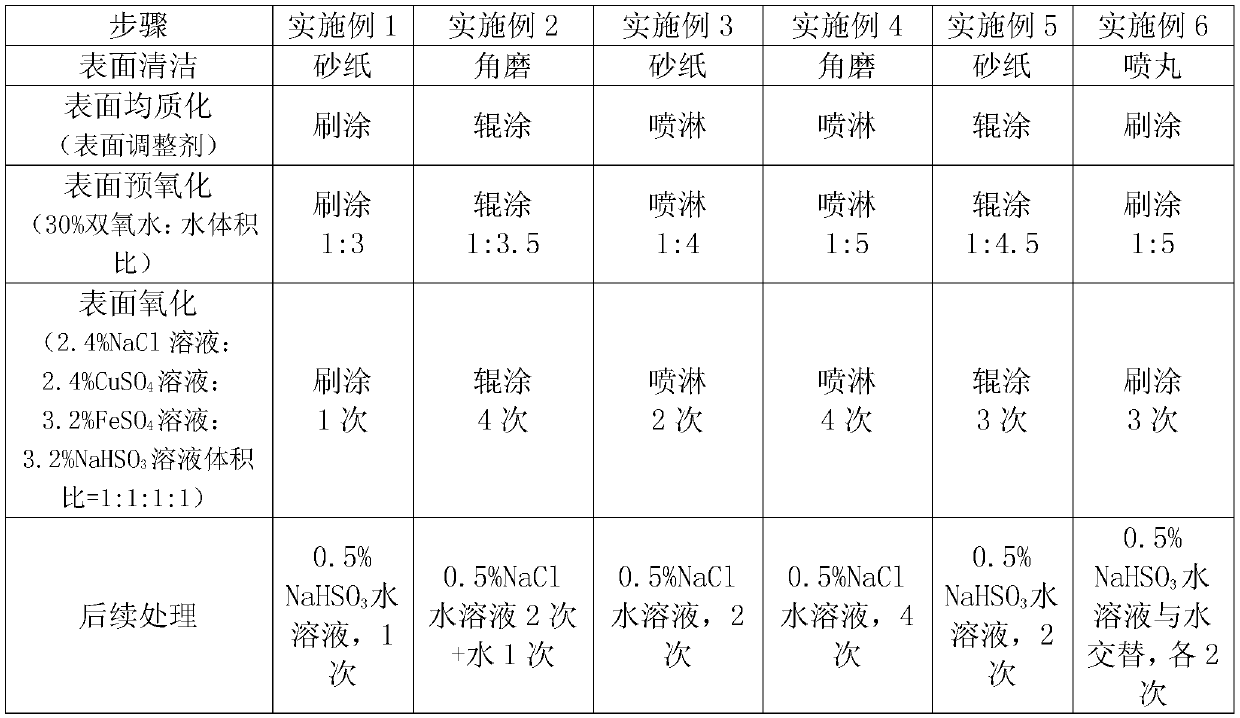

[0025] The technological process of the rapid corrosion method for the weather-resistant steel plate of the present invention is: cleaning of the steel plate surface → homogenization of the steel plate surface → pre-oxidation of the steel plate surface → oxidation of the steel plate surface → subsequent treatment of the steel plate surface. The specific corrosion methods and steps are:

[0026] 1. Clean the surface of the steel plate: Use sandpaper, angle grinder or shot blasting to treat the surface of the steel plate manually or mechanically, so that the surface of the steel plate is free of rust, oil and other adherents.

[0027] 2. Homogenization of steel plate surface: use brush coating, roller coating or spraying method to attach nickel salt solution to the surface of steel plate to make the active points and inactive points on the surface of steel plate uniform, increase the number of active points on the surface of steel plate, and promote The initial formation of subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com