Preparation process of gradient coating on surface of automobile hub

A surface gradient and automobile wheel technology, which is applied in the direction of pressure inorganic powder coating, rolling resistance optimization, road transportation emission reduction, etc., can solve the problem of low coating density, reduce pores in the coating, and improve adhesion , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

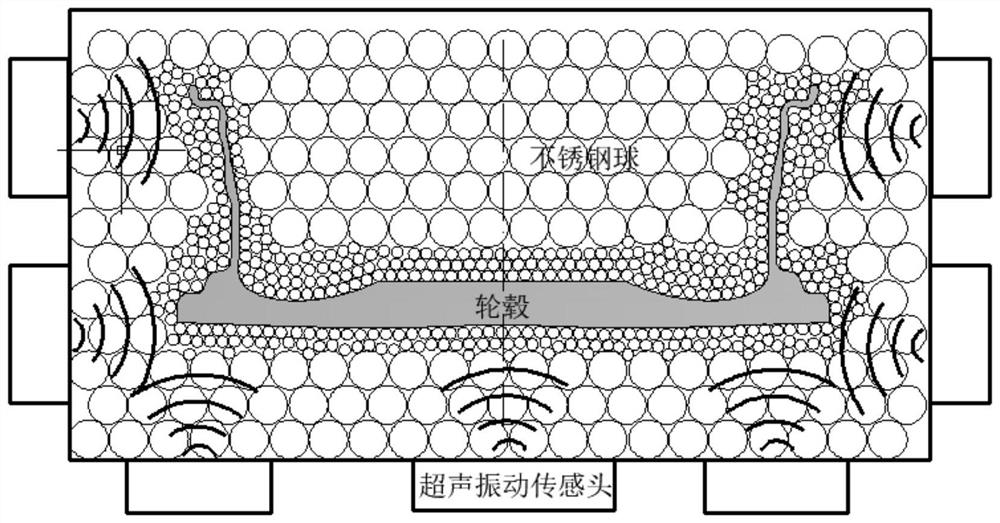

[0037] A preparation process of a gradient coating on the surface of an automobile wheel hub, comprising the following steps:

[0038] 1) Three materials required for the preparation of gradient coatings: Al x FeNiSiTi high entropy alloy powder, Al x FeNiSiTi high entropy alloy powder + 5vol.% SiC mixed powder and Al x FeNiSiTi high-entropy alloy powder + 10vol.% SiC mixed powder; Al x The range of x in FeNiSiTi high entropy alloy powder is 0.2~1.0, Al x The diameter of FeNiSiTi high-entropy alloy powder particles is 300-1000 mesh, and the particle diameter of SiC is 300-1500 mesh; the volume fraction of SiC in the gradient coating mixed material is 1-10 vol.%, and the thickness of each material in the gradient coating 20~50μm;

[0039] 2) Using cold spray technology, the Al x FeNiSiTi high-entropy alloy powder is uniformly sprayed on the surface of the aluminum alloy wheel hub;

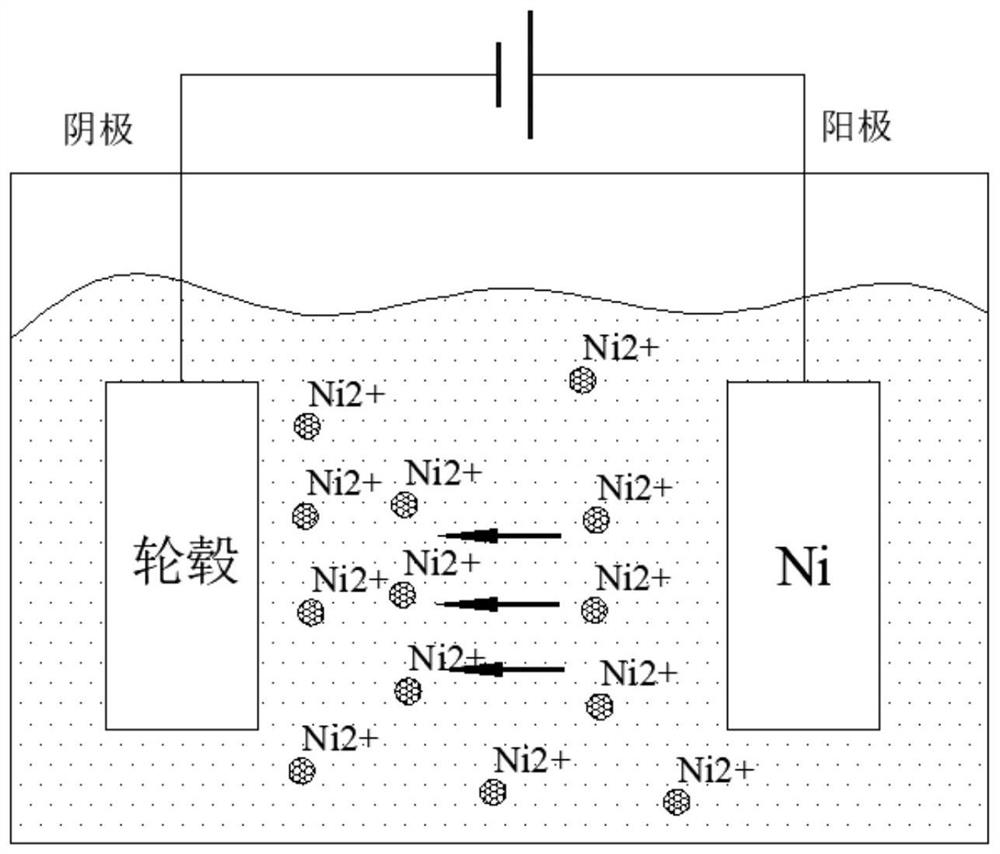

[0040] 3) The composite electrodeposition process is adopted, the hub is the cathode, and the...

Embodiment 1

[0046] A process method for preparing a high-hardness corrosion-resistant wheel hub coating, comprising the following steps:

[0047] 1) In a vacuum atmosphere, configure three coating materials: Al x FeNiSiTi high entropy alloy powder; Al x FeNiSiTi high-entropy alloy powder + 10vol.% SiC mixed powder; Al x FeNiSiTi high-entropy alloy powder + 10 vol.% SiC mixed powder (respectively denoted as material-1 / 2 / 3).

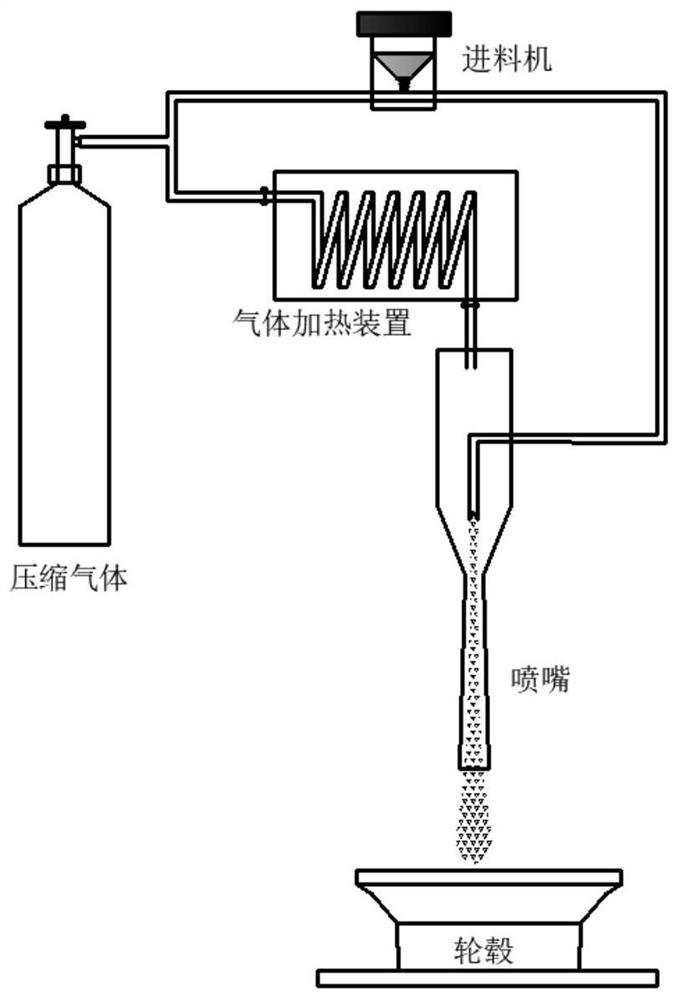

[0048] 2) as figure 1 As shown in the figure, the material-1 is uniformly sprayed on the surface of the aluminum alloy wheel hub by the cold spraying technology. The working gas of the cold spraying system is nitrogen, the air pressure is 1.2MPa, the spraying temperature is 300℃, the spraying distance is 12mm, and the moving speed is 10mm / s . After spraying, a coating with a thickness of 30 μm was obtained, which was loose and had many pores.

[0049] 3) as figure 2 As shown, the composite electrodeposition process is adopted, the hub sprayed with material-1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com