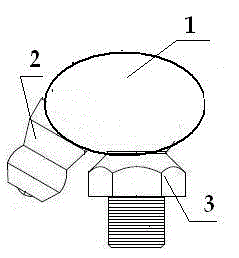

Novel acute-angle grease nipple structure

A grease nipple and acute angle technology, which is applied in the field of new sharp angle grease nipple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The adjusting slider 10 is located in the upper sleeve 6 of the valve core above the moving slider 3 , and the lower plane of the adjusting slider 10 realizes the closing and sealing of the cold water inlet by pressing the cold water sealing ring 5 embedded in the upper plane of the moving slider 3 . There is a temperature-sensing element 4 inside the moving slider 3, and the heat-sensitive wax installed inside the temperature-sensing element 4 can expand and contract with the rise and fall of temperature, and the expansion and contraction of the heat-sensitive wax pushes the push rod inside the temperature-sensing element to move up and down . The outer middle section of the adjustment slider 10 is equipped with an outer hexagonal structure, and the interior of the valve core upper sleeve 6 is equipped with an inner hexagonal structure. The adjustment slider 10 is assembled into the valve core upper sleeve 6. It can move up and down, but cannot rotate relative to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com