All-plastic heat-conducting insulating type LED fluorescent lamp production method

A technology of heat conduction insulation and heat conduction insulation materials, applied in the field of LED fluorescent lamp lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

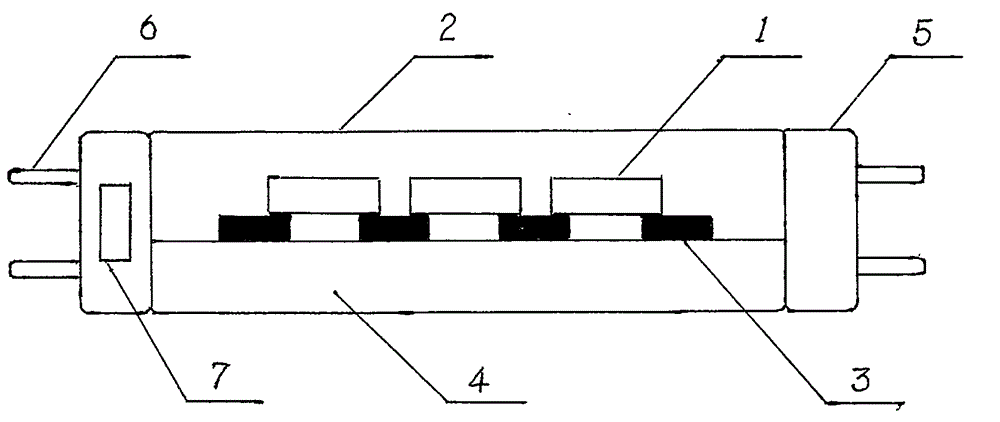

[0006] The present invention as figure 1 shown

[0007] The alternating current is connected to the LED constant current driver 7 through the alternating current contact point 6, and after passing through the constant current driver, it is connected to the circuit 3 of the conductive silver glue through a wire. The LED chip 1 is welded on the positive and negative poles of the conductive silver glue circuit. The heat generated by the LED chip passes through the heat-conducting insulating plastic base 4 to transfer heat and diffuse into the air. 2 is an LED fluorescent lamp lampshade, and 5 is an insulating lamp holder.

[0008] The effective effect of the present invention is: first, the conductive silver glue is printed on the plane of the plastic base of the heat-conducting and insulating LED fluorescent lamp according to the required circuit by screen printing technology, and the alternating current passes through the AC contact point of the LED fluorescent lamp to connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com