Omnidirectional LED bulb lamp

A technology of LED bulb lamps and LED lamp beads, which is applied in the direction of lampshades, cooling/heating devices of lighting devices, lighting and heating equipment, etc., and can solve problems such as high light decay, affecting lamp life, and high heat generation of LED bulb lamps. , to achieve the effect of solving large heat generation, avoiding high light decay of LEDs, and realizing full-angle light distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

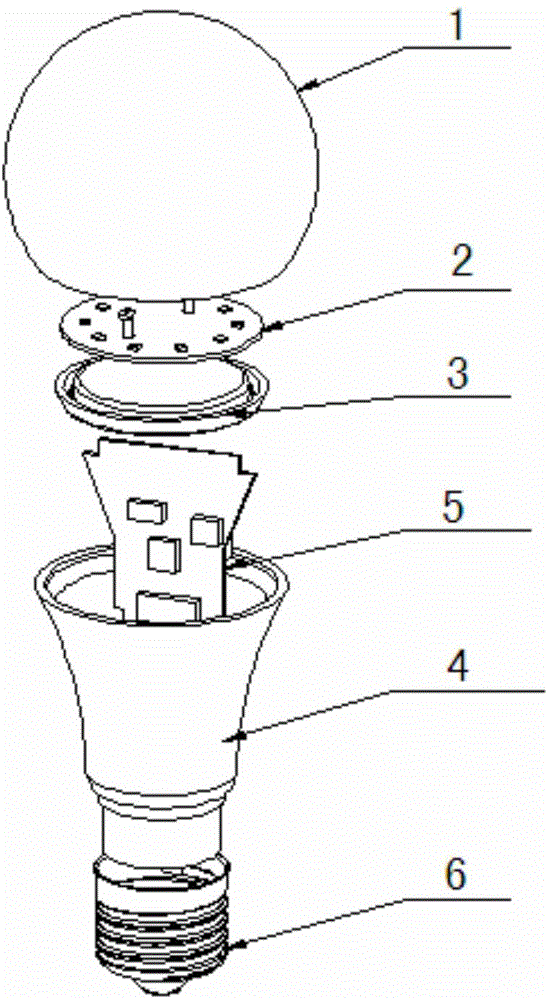

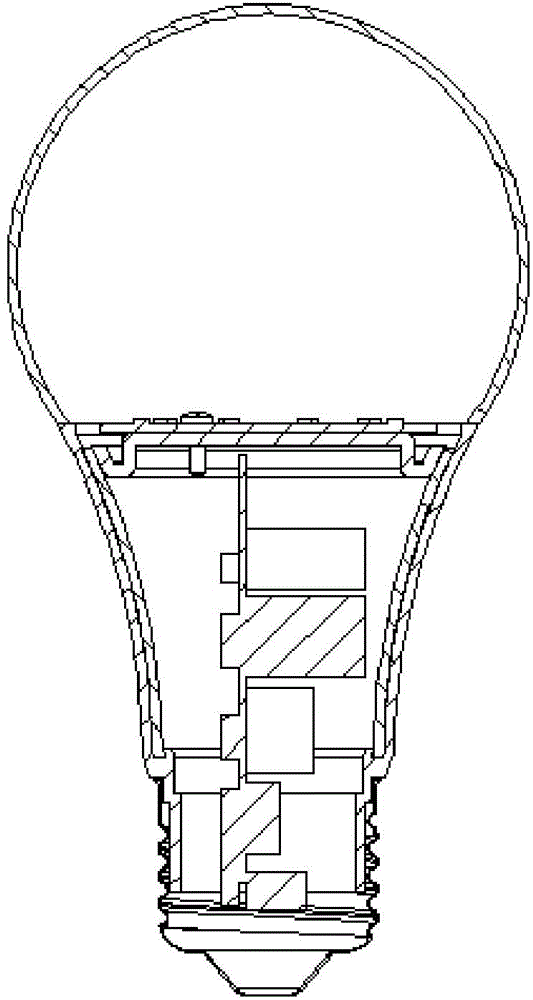

[0020] Such as figure 1 As shown, a full-angle LED bulb lamp includes a bulb shell 1, LED lamp beads, an aluminum substrate 2, an aluminum gland 3, a lamp body 4, a driving PCB board 5 and a lamp holder 6;

[0021] Specifically, such as figure 1 As shown, the material of the bulb 1 is a high-diffusion resin and is fixedly connected to the lamp body 4 through a buckle structure; The angle is greater than 150°; the aluminum substrate 2 is fixed with the aluminum gland 3 by screws; the aluminum gland 3 is pressed and fixed with the lamp body 4; the PCB board 5 is fixed in the lamp body 4 through a card slot; the lamp cap 6 is connected with the lamp through a spiral structure Body 4 is fixedly connected.

[0022] In the above-mentioned embodiments, the high-diffusion resin is used as the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com