Ground smoke channel air returning furnace

A technology of return air furnace and floor smoke, which is used in household furnaces/stoves, lighting and heating equipment, solid heating fuels, etc., can solve problems such as large use space, flue burns, occupation, etc. Clean and beautiful, the effect of increasing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

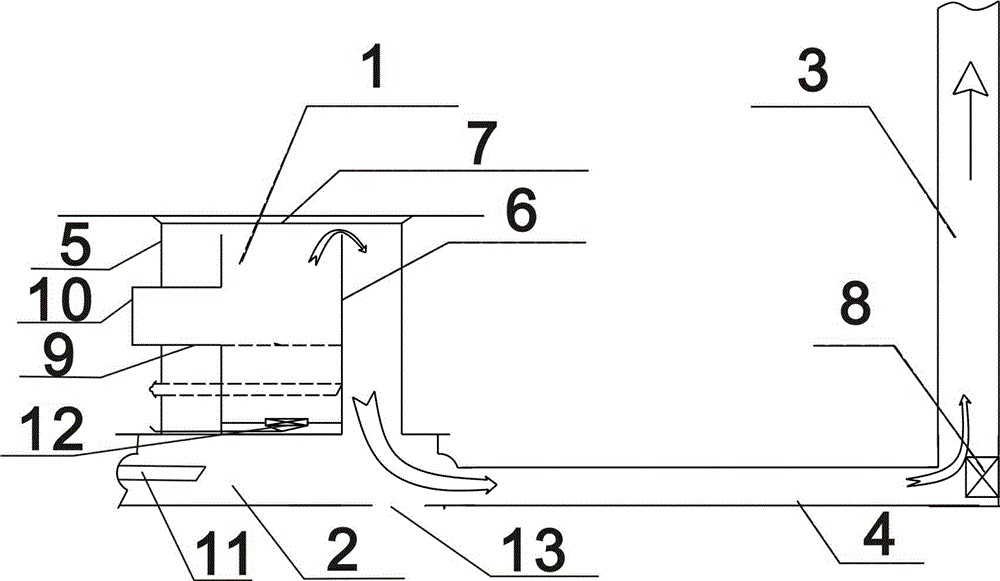

[0014] A ground flue return air furnace, including a furnace body 1, a foot box 2, and a smoke pipe, wherein the smoke pipe includes a straight smoke pipe 3 and a horizontal smoke pipe 4, wherein the foot box 2 and the furnace body 1 are connected through an interlayer tempering channel , the straight smoke pipe 3 is connected with the foot box 2 through the horizontal smoke pipe 4. At the corner of the straight smoke pipe 3 and the horizontal smoke pipe 4, an ash removal and ignition device 8 is arranged. The horizontal smoke pipe 4 is arranged close to the ground or buried underground, and its shape is cylindrical, semi-cylindrical or cube-like.

[0015] The tempering passage is an interlayer formed by the outer cylinder 5 and the inner tank 6 .

[0016] A fire-proof cover 7 is arranged on the furnace surface of the furnace body 1 .

[0017] The bottom plate of the foot box 2 is provided with a dust removal port 13 .

[0018] The inner tank 6 is also provided with a furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com