Serrated air outlet air knife structure for glass cleaning/drying machine

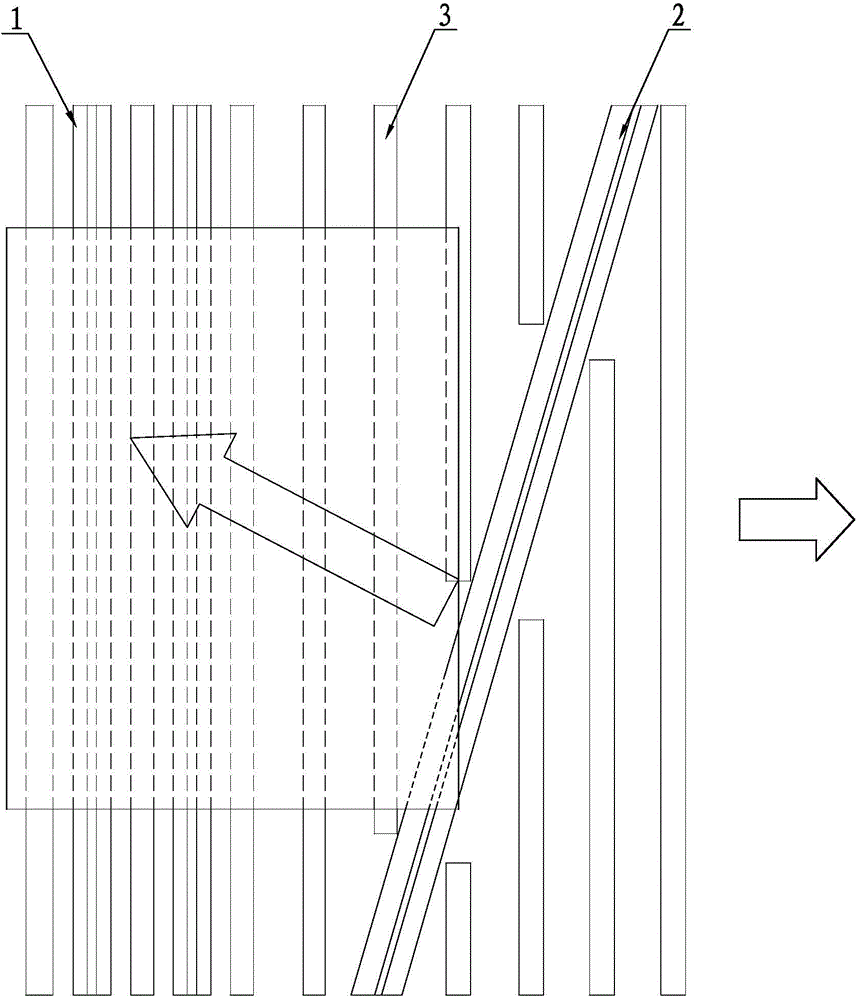

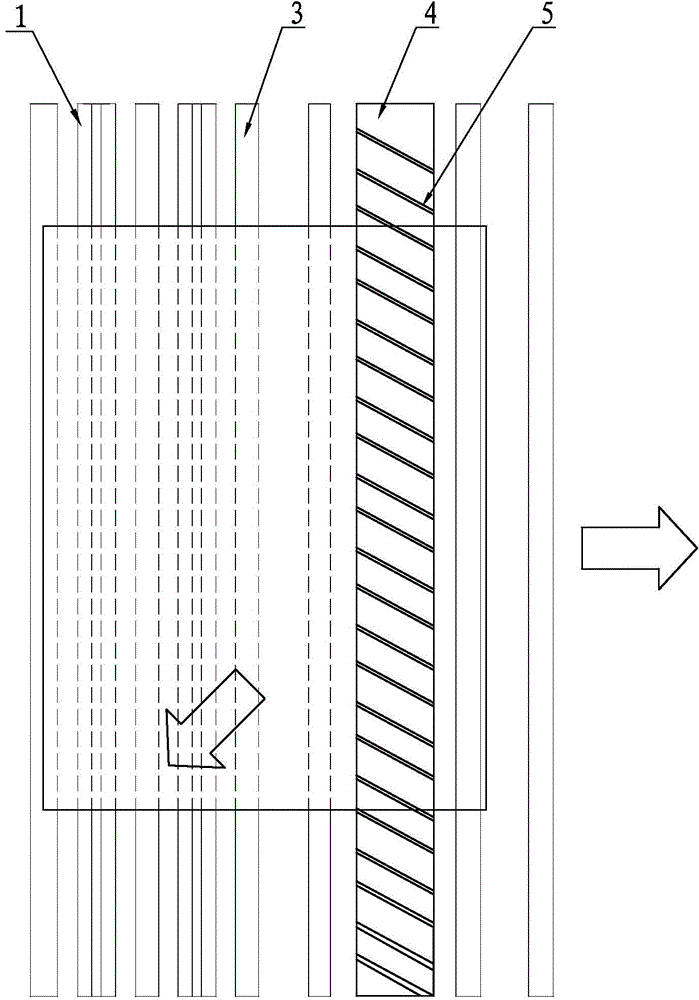

A glass cleaning and air outlet technology, applied in dryers, drying gas arrangement, drying, etc., can solve the problems of affecting the drying effect, incorrect air outlet angle, and increased energy consumption of air knives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

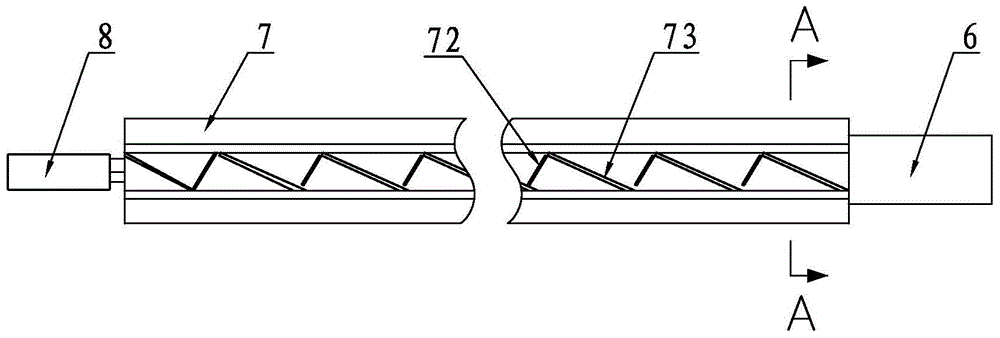

[0027] A sawtooth air outlet air knife structure for a glass washing and drying machine, comprising an air inlet pipe 6, a sawtooth air outlet air knife body 7 and a fixed shaft 8 at the tail of the air knife, an air inlet pipe 6, a sawtooth air outlet air knife body 7 and a wind The fixed shaft 8 at the tail of the knife is coaxially connected, and the air inlet pipe 6 is fixedly installed on the air inlet end of the sawtooth air outlet air knife body 7, and communicates with the inner chamber 71 of the sawtooth air outlet air knife body 7, and the fixed shaft at the end of the air knife 8 is fixedly installed on the corresponding end of the air inlet end of the zigzag air outlet air knife body 7, and the zigzag air outlet air knife body 7 is fixedly installed between two adjacent rubber rollers 3 and parallel to the rubber rollers 3, and the zigzag air outlet air The top surface of the cutter body 7 is inclined along the length extension direction and has a plurality of zigza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com