Position measuring method for pole-mounted transformer

A pole-mounted transformer and measurement method technology, applied to measuring devices, mechanical measuring devices, instruments, etc., can solve problems such as inaccurate measurement results, high risk factors, and unchanged use and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

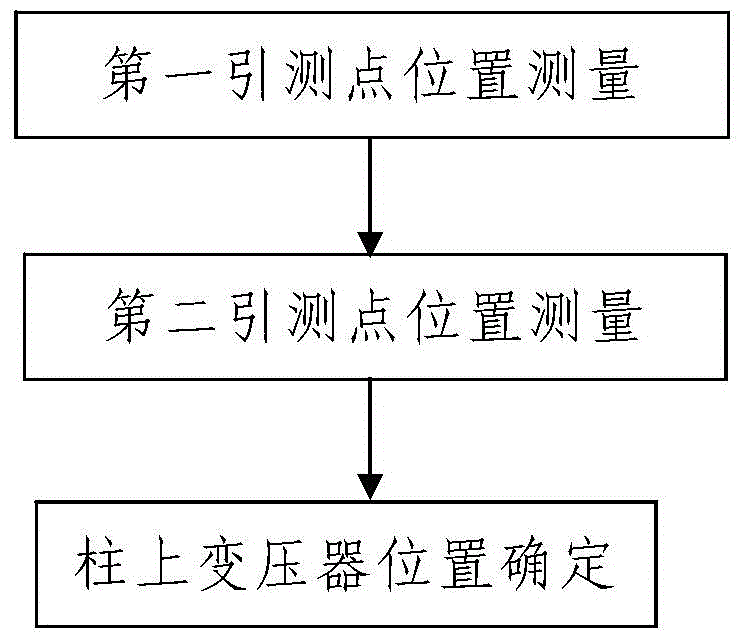

[0049] Such as figure 1 A method for measuring the position of a pole-mounted transformer includes the following steps:

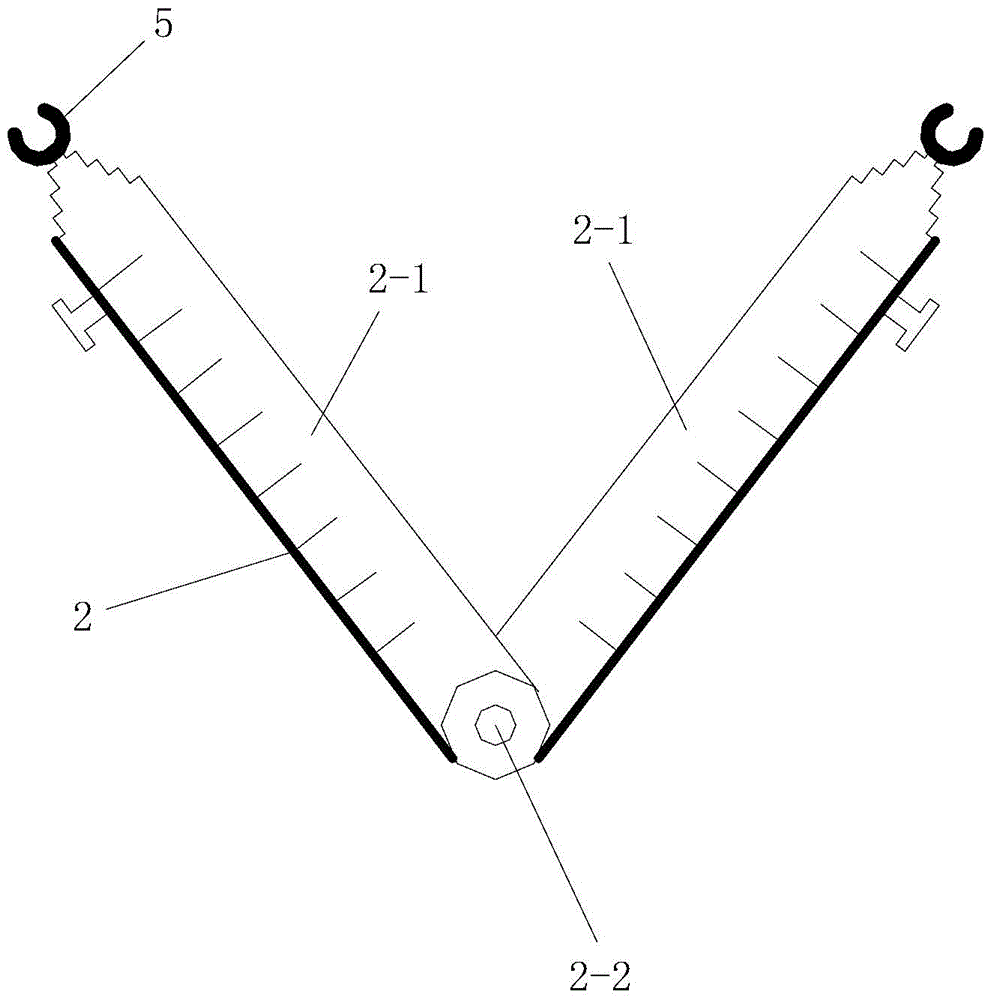

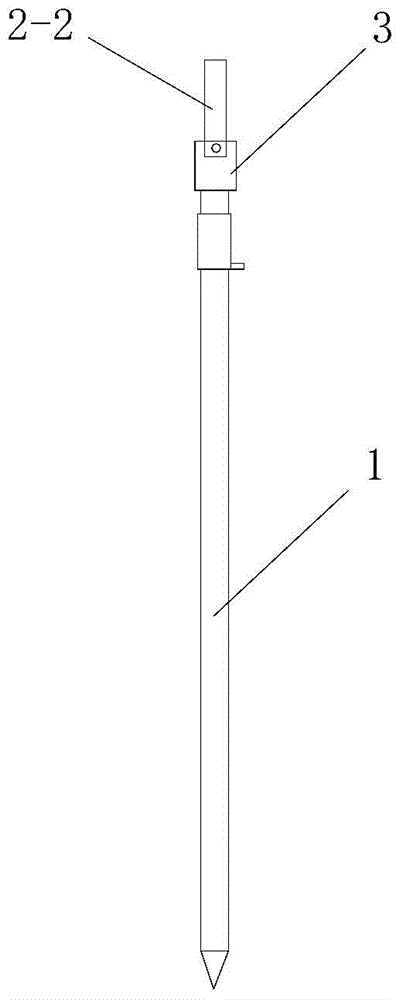

[0050] Step 1. Measurement of the position of the first lead measuring point: use the auxiliary measuring device to measure the position of the first lead measuring point below the side of the transformer on the measured column; figure 2 , image 3 As shown, the auxiliary measuring device includes a V-shaped measuring ruler 2 and a centering rod 1 installed under the rear part of the V-shaped measuring ruler 2 and capable of swinging back and forth on a vertical plane. The V-shaped measuring ruler 2 includes left and right Two measuring rulers 2-1, the structure and size of the two measuring rulers 2-1 are the same and the two are symmetrically arranged left and right, and the rear ends of the two measuring rulers 2-1 are connected in a hinged manner And the rear ends of the two are installed on the hinge shaft 2-2, and the rear ends of the two measuring...

Embodiment 2

[0088] In this embodiment, different from Embodiment 1, the V-shaped measuring ruler 2 described in step 201 and the V-shaped measuring ruler 2 described in step 101 are all located on the same side of the transformer on the measured column; The second testing point and the first testing point in step 102 are located on the same side of the point C to be tested, and L B > L A . In this way, the actual measurement is very simple. After the first point to be measured is determined in step 1, the V-shaped measuring ruler 2 used in step 1 is stretched horizontally to the outside, and the second lead measurement point is determined accordingly.

[0089]In this embodiment, when determining the position of the transformer on the pole in step 3, the two-dimensional coordinates (x A ,y A ) and the two-dimensional coordinates (x B ,y B ), and according to the formula Δx = x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com