Device and method for testing friction force of cylinder liner and piston assembly

A technology of piston assembly and testing device, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as lack of deviation between measured values and actual values, and reduce the influence of tightening pressure on test results. Eliminate the interference of test results and the effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

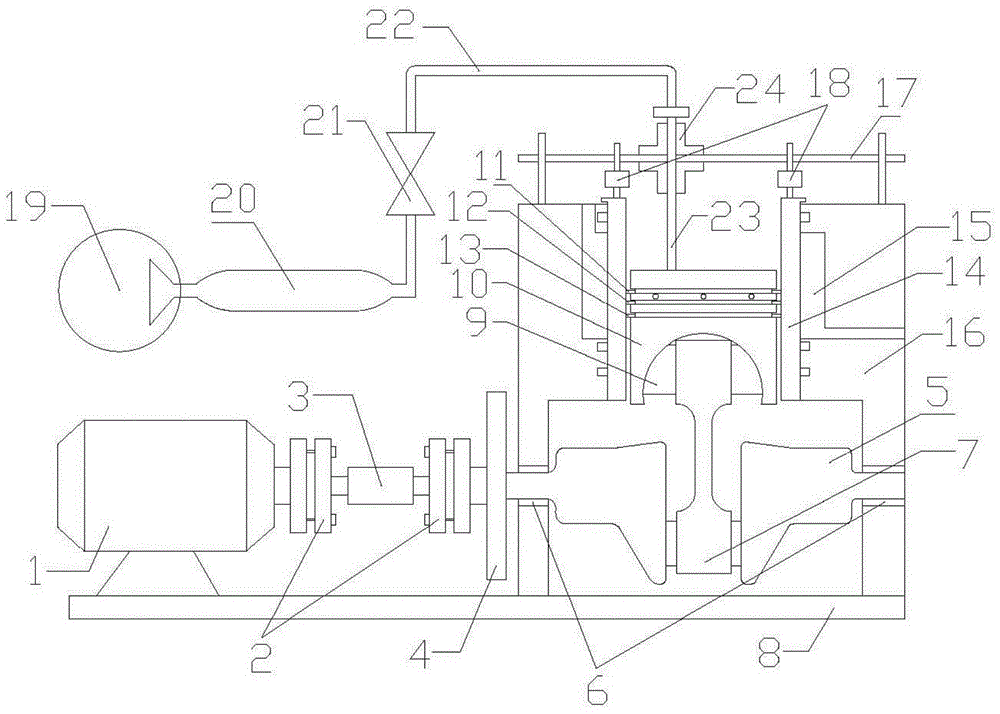

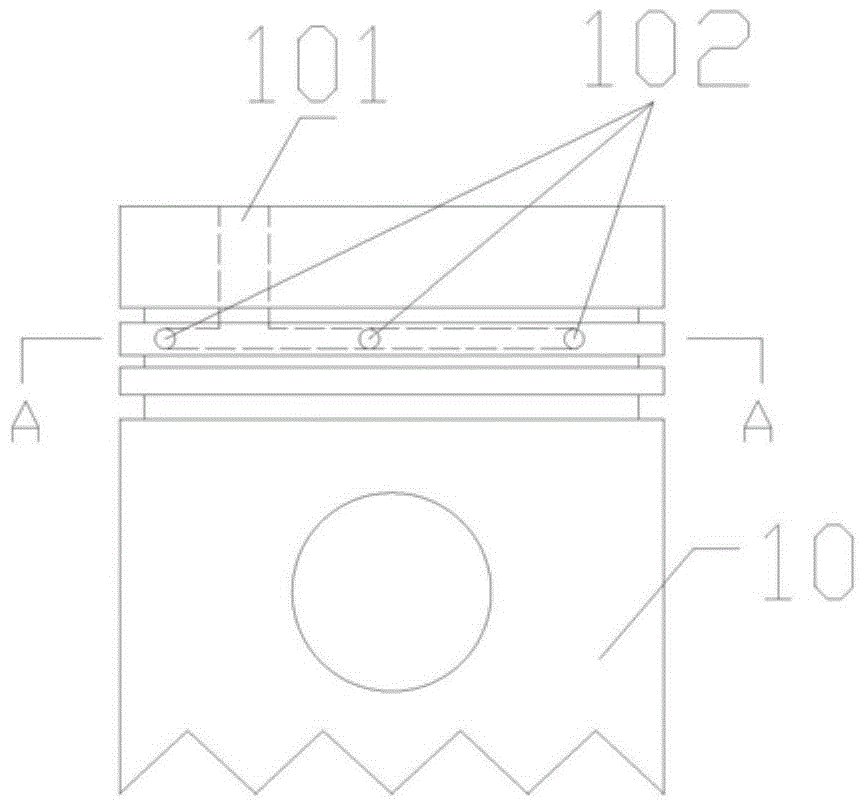

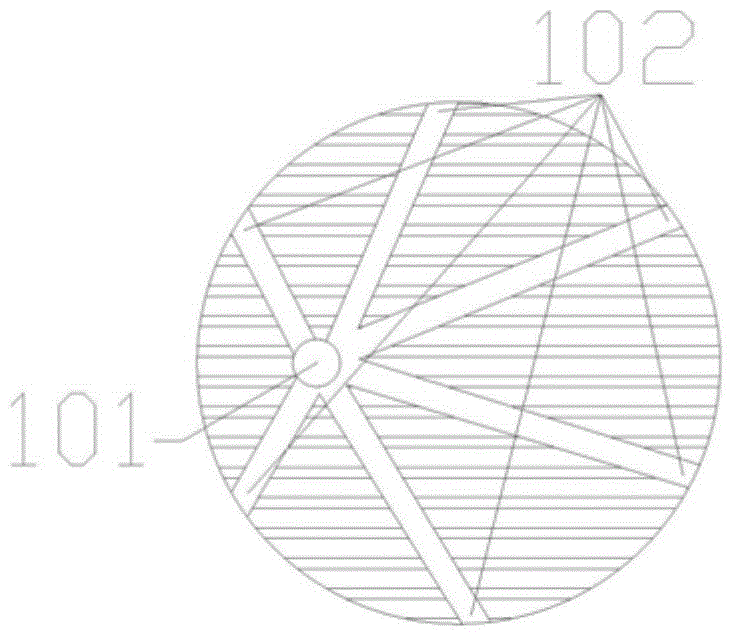

[0024] A test device for the friction force of a cylinder liner and a piston assembly, the device includes a motor 1, a coupling 2, a torque sensor 3, a flywheel disc 4, a crankshaft 5, a bearing 6, a connecting rod 7, a support platform 8, and a piston pin 9 , piston 10, air intake hole 101, air outlet hole 102, first air ring 11, second air ring 12, scraper ring 13, cylinder liner 14, heating / cooling chamber 15, cylinder block 16, baffle plate 17, Friction sensor 18, air compressor 19, high pressure cylinder 20, pressure reducing valve 21, high pressure hose 22, high pressure hard pipe 23, guide rail 24, described motor 1 and cylinder body 16 are fixed on the support platform 8, described The motor 1 is connected with the crankshaft 5 through the shaft coupling 2, the torque sensor 3, the flywheel disc 4, the crankshaft 5 is fixed on the cylinder block 16 through the bearing 6, one end of the connecting rod 7 is connected with the crankshaft 5, and the connecting rod The oth...

Embodiment 2

[0026] A method utilizing the device described in Embodiment 1 to test the frictional force of the cylinder liner and the piston assembly, said method comprising the steps of:

[0027] Open the heating / cooling chamber 15, and adjust the temperature of the inner wall of the cylinder liner 14 to 70°C;

[0028] ② Turn on the motor 1, the motor 1 drives the crankshaft 5 to rotate, and the crankshaft 5 drives the connecting rod 7 to convert the rotational motion into the reciprocating motion of the piston 10;

[0029] ③ Turn on the air compressor 19, adjust the air pressure to 10MPa, so that the high-pressure gas enters from the air inlet 101 and exits from the air outlet 102, and applies radial pressure to the first air ring 11 and the second air ring 12;

[0030] ④ The friction force between the first air ring 11, the second air ring 12, the piston 10 and the cylinder liner 14 is transmitted to the friction force sensor 18 through the cylinder liner 14 for measurement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com