Testing device for filtering performance test of high humidity dust-containing smoke

A filter performance testing and testing device technology, applied in measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve the problems of high viscosity, weak adaptability, difficult to clean, etc., to achieve the effect of simple operation and stable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

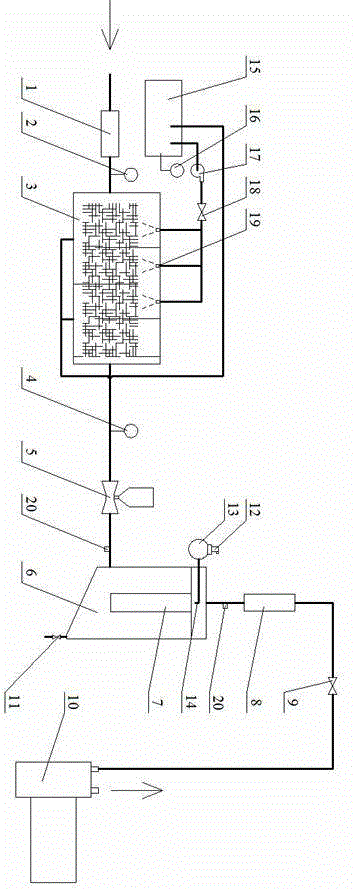

[0013] Such as figure 1 As shown, it is a schematic diagram of the system connection of the test device used for the filtration performance test of high-humidity dusty flue gas. The test device for testing the filtration performance of high-humidity dust-laden flue gas includes three parts: a flue gas generating and filtering system, a soot cleaning and injection system, and a flue gas humidity control system. The flue gas generation and filtration system includes a flue gas heater 1, a flue gas temperature controller 2, a spray humidifier 3, a flue gas temperature and humidity controller 4, a dust generating device 5, a filtering device 6, a filter material fixing device 7, and a flue gas flow rate Meter 8, flue gas flow control valve 9, blower fan 10 and ash discharge valve 11, all components are connected by stainless steel pipes, the filter material fixing device 7 is fixed inside the filter device 6, and the measuring holes 20 are respectively set at the inlet and outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com