Detection method for defects of compound insulator, equipment and system

A technology for composite insulators and defects, applied in the field of electric power, can solve problems that affect the accuracy of detection results, no detection, abnormal temperature rise of composite insulators, etc., and achieve the advantages of improving convenience and application range, improving accuracy, and strong penetrating ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

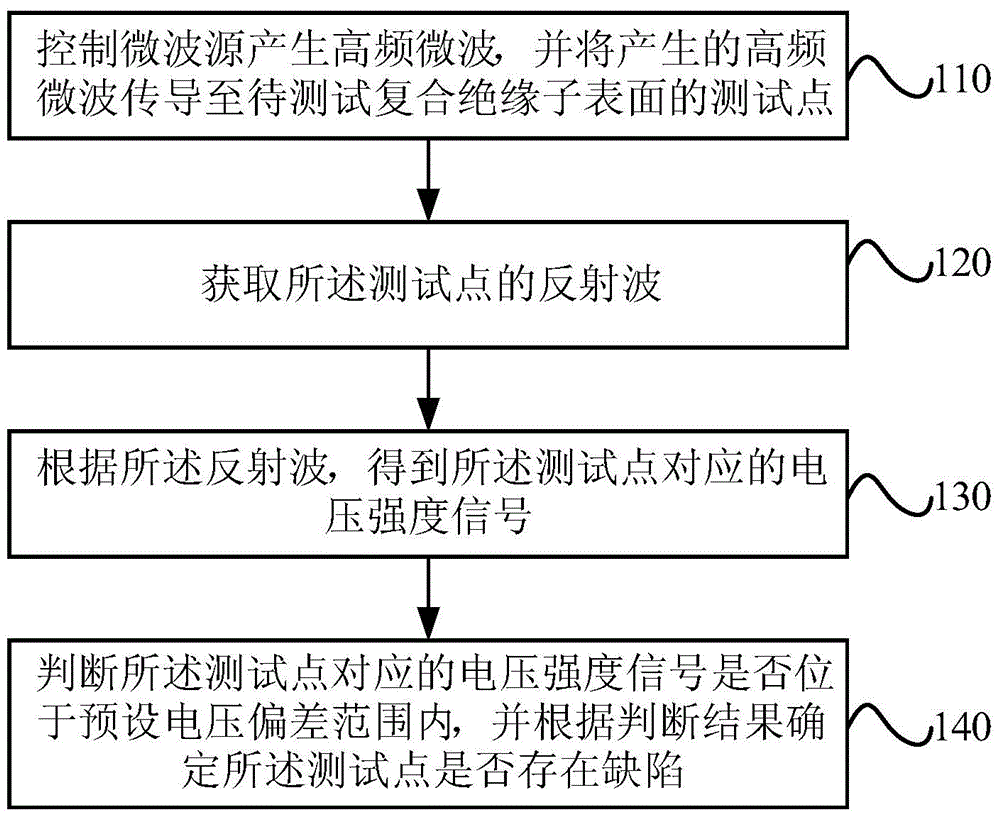

[0032] see Figure 1a , is a flow chart of a method for detecting defects of a composite insulator provided in Embodiment 1 of the present invention.

[0033] The method includes: step 110 - step 140 .

[0034] Step 110, controlling the microwave source to generate high-frequency microwaves, and transmitting the generated high-frequency microwaves to test points on the surface of the composite insulator to be tested.

[0035] In this step, the frequency of the high-frequency microwaves generated by the microwave source may be above 10 GHz. The detection accuracy of composite insulator defects is positively correlated with the frequency of high-frequency microwaves emitted by microwave sources, that is, the higher the frequency of high-frequency microwaves emitted by microwave sources, the higher the detection accuracy of composite insulator defects; The lower the frequency of the microwave, the lower the detection accuracy of the defects of the composite insulator.

[0036] ...

example 1

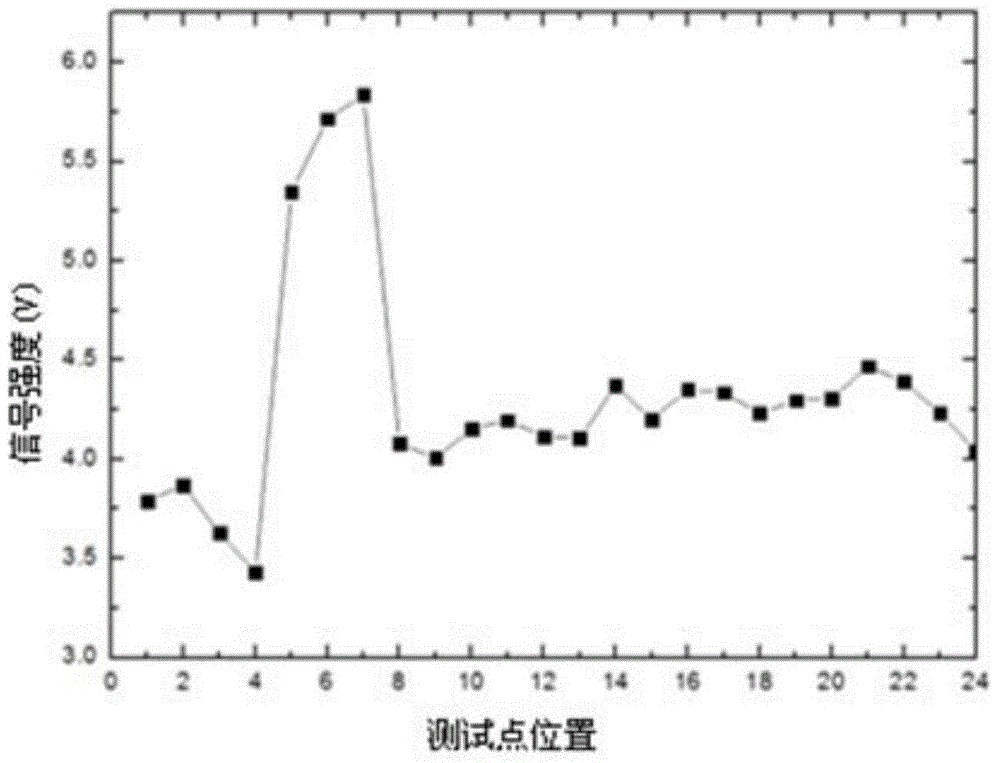

[0056] In this example, a series of pore defects with a diameter of 1 mm were artificially manufactured in the composite insulator to be tested, and 24 test points were detected along a circumferential surface of the composite insulator to be tested. The microwave source was controlled to generate high-frequency microwaves with a frequency of 24 GHz, and Conduct the generated high-frequency microwaves to 24 test points on the surface of the composite insulator to be tested; obtain the reflected waves of each test point, and obtain the corresponding voltage intensity signal of each test point, such as Figure 1c As shown, where the abscissa is the position of the test point, and the ordinate is the voltage intensity signal of the reflected wave corresponding to each test point, it can be seen that the voltage intensity signal of the reflected wave at the non-defect position is distributed within the range of 4.0V±0.6V, The average value of the voltage intensity signal of the ref...

example 2

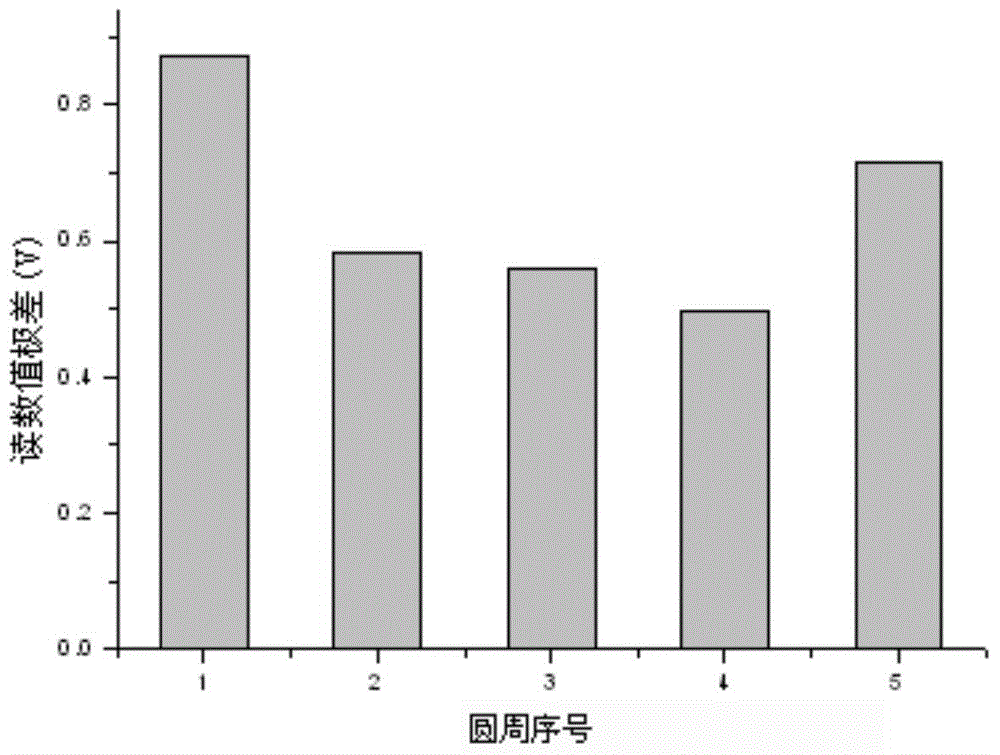

[0059] In this example, the composite insulator to be tested is a composite insulator taken from the N46 tower of Lingshen Line B, and 24 test points are detected along a circumferential surface of the composite insulator to be tested, and the microwave source is controlled to generate high-frequency microwaves with a frequency of 24GHz. And conduct the generated high-frequency microwaves to 24 test points on the surface of the composite insulator to be tested; obtain the reflected waves of each test point, and obtain the corresponding voltage intensity signal of each test point, such as Figure 1d As shown, where the abscissa is the position of the test point, and the ordinate is the voltage intensity signal of the reflected wave corresponding to each test point, it can be seen that the voltage intensity signal of the reflected wave at most positions is distributed within the range of 6.9V±0.5V, Therefore, the average value of the voltage intensity signal of the reflected wave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com