Manufacturing method of optical waveguide embedded optical printed circuit board

A technology of optical printing and manufacturing method, applied in the direction of optical waveguide, light guide, etc., can solve problems such as loss, and achieve the effect of improving conversion efficiency, reducing process, and easy interconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

[0041] see Figures 1 to 9 , a method for manufacturing an optical waveguide embedded optical printed circuit board, comprising the steps of:

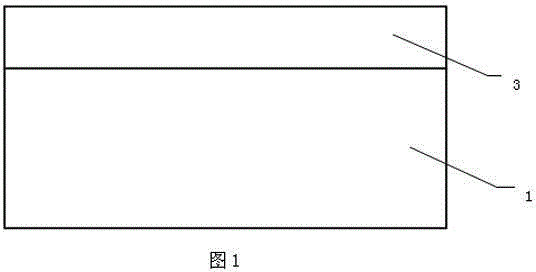

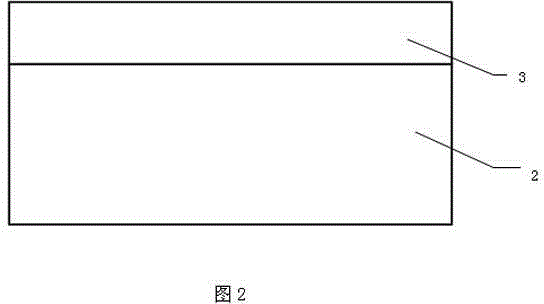

[0042] S1. Thin film coating: the surface of the first plate (1) and the second plate (2) are coated with a layer of low optical refractive index material (3), and the surface coating can be spin coating or coil coating and silk screen coating, the thickness of the coated low optical refractive index material (3) is thicker than the depth of the first groove (5) in step S2 and the depth of the second groove (7) in step S4 . The size of the first pit (5) is the same as that of the second pit (7).

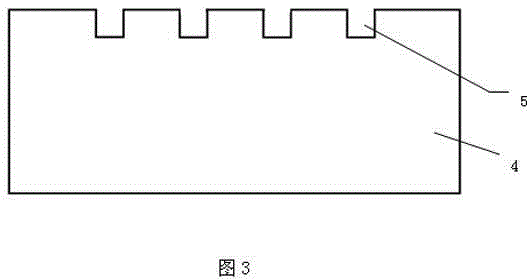

[0043] S2. Manufacture of the main body: the material of the main body (4) is manufactured by traditional photolithography technology or injection molding method. There are first pits (5) of different shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com