Laser direct writing method based on large-area multi-step binary optical element

A binary optical element, laser direct writing technology, applied in microlithography exposure equipment, diffraction grating, photolithography process exposure device and other directions, can solve the problem of high precision, large area, multi-step binary optical exposure efficiency has no advantages problems, to achieve the effects of precise control of exposure metering, improved lithography efficiency, and reduced error probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the specific embodiments shown in the drawings. However, these embodiments do not limit the present invention, and the structural, method, or functional changes made by those skilled in the art based on these embodiments are all included in the protection scope of the present invention.

[0039] The invention discloses a laser direct writing method based on a large area multi-step binary optical element, including:

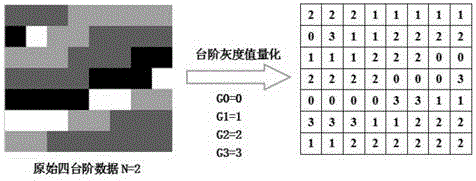

[0040] S1, will 2 N The second step data file is processed into gray value starting from G0=0 to G2 N -1=2 N -1 gray-scale BMP image ending, where 0 represents a step that is not etched, 2 N -1 means the step with the deepest etching depth;

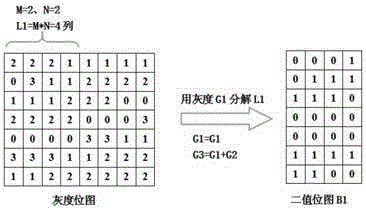

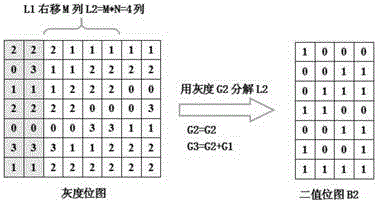

[0041] S2, the cumulative formula of exposure measurement P=P1+P2+…+Pn, Pn=2 n-1 *P1(n N Exposure measurement required for sub-step exposure, and divide the gray-scale BMP image into a number of binary BMP bitmap queues B1 to Bm with L=M*N columns;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com