Vibration absorber, method of reducing disturbing vibration, and photolithography machine

A vibration damper and vibration isolator technology, which is applied in the field of photolithography machines, can solve the problems of reducing the vibration damping effect and the vibration damper cannot be isolated, and achieve the effects of improving the vibration damping effect, reducing production costs, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

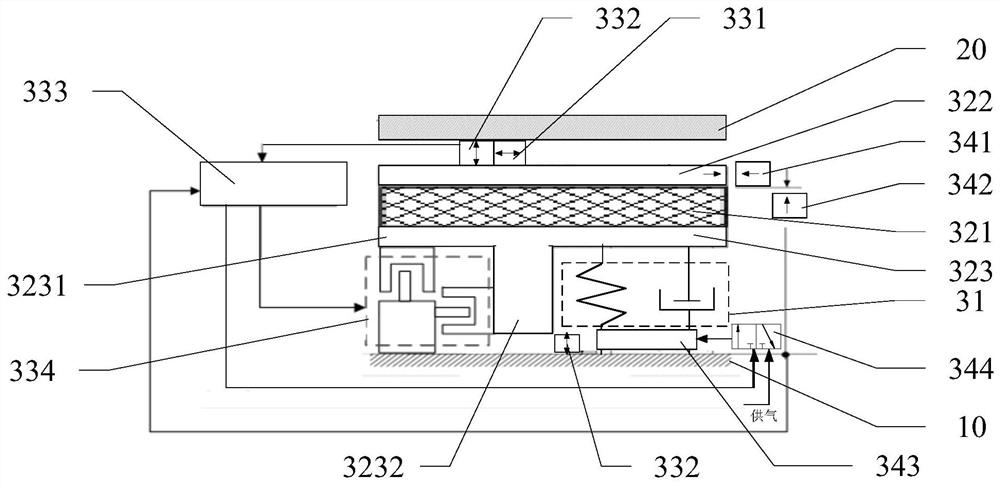

[0033] See figure 2 , a photolithography machine, including a base 10, a machine load 20, and a shock absorber arranged between the base 10 and the machine load 20, the shock absorber makes the base 10 and the An elastic connection is formed between the machine loads 20 to reduce the transmission of vibrations.

[0034] The vibration absorber includes a series connection of a vibration isolator and a damper, the vibration isolator is connected to the base 10 , and the damper is connected to the machine load 20 . In this embodiment, the vibration isolator is an air spring 31, and the vibration transmission rate formula of the air spring 31 is:

[0035]

[0036] Among them, M is the load mass, C 1 is the air spring damper, K 1 is the stiffness of the air spring, and s is a complex variable (complex field).

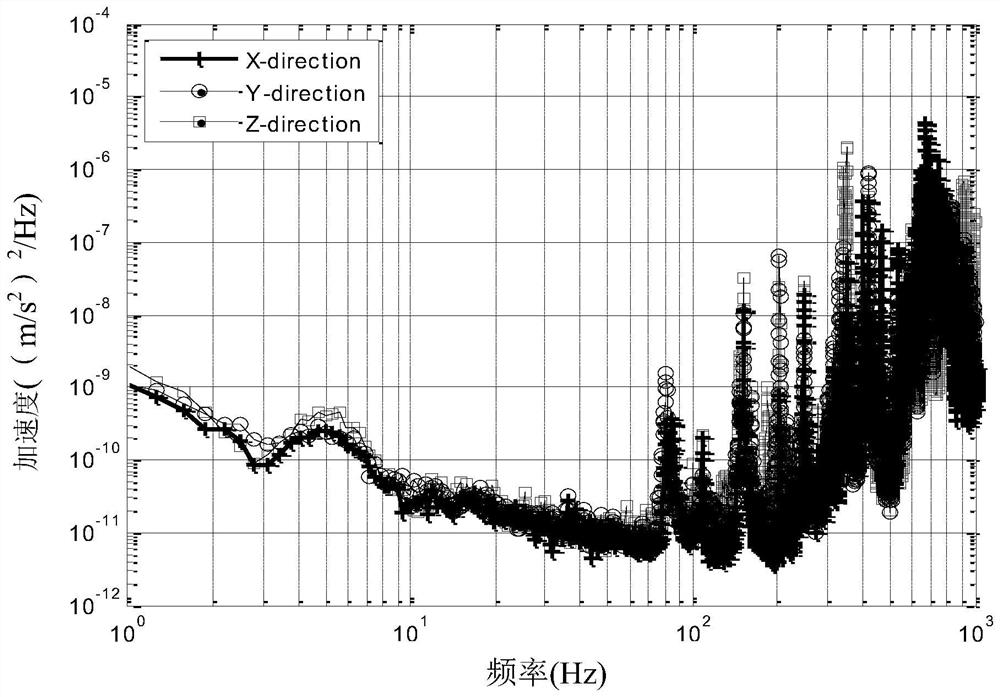

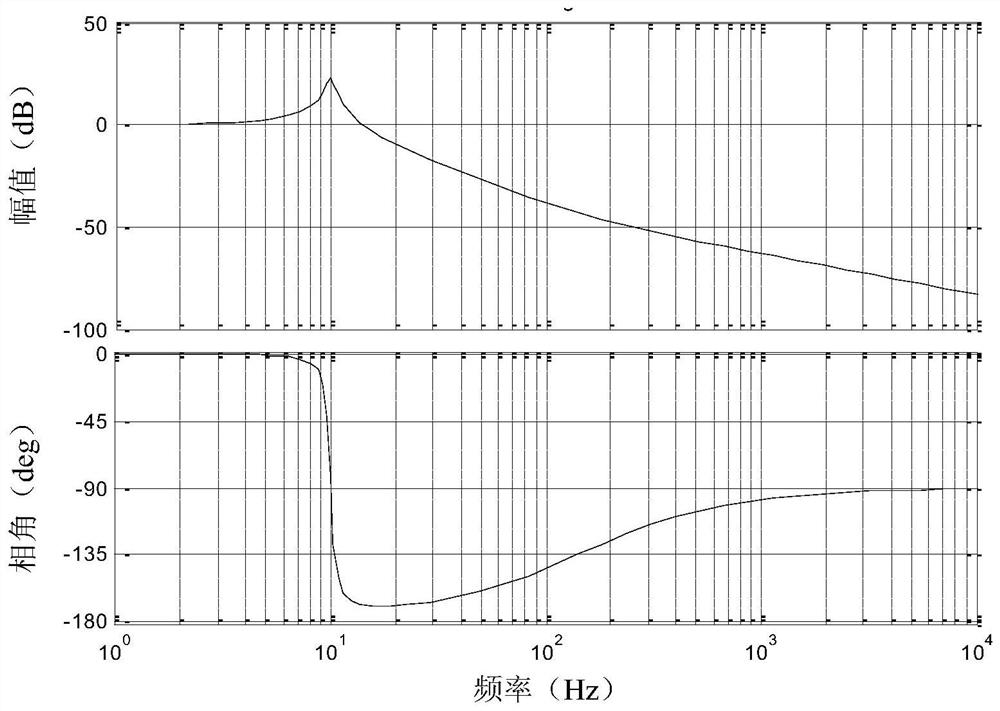

[0037] The vibration transmission rate curve of the air spring 31 is shown in image 3 , represented by a Bode diagram, which consists of two diagrams: one is the a...

Embodiment 2

[0052] See Image 6 The difference between the second embodiment and the first embodiment is that the vibration isolator is a steel spring 35, one end of the steel spring 35 is connected to the base 10, and the other end is connected to the damper, and the control valve is the The controller 343 adjusts the elongation of the steel spring 35 through the controller 343 . The vibration is transmitted to the shock absorber through the base 10. Firstly, the steel spring 35 performs vibration isolation on the incoming vibration. The steel spring 35 has a self-vibration phenomenon, and it is easy to transmit the intermediate frequency vibration of 6-100 Hz. The steel spring 35 has a small critical damping ratio and poor vibration isolation capability near the resonance frequency. Therefore, the rubber spring 321 is connected in series with the steel spring 35 to effectively isolate the vibration that the steel spring 35 cannot isolate. At the same time, when vibrations are generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com