A wide beam scanning exposure method

A technology of scanning exposure and wide beam, applied in the field of scanning exposure, can solve problems such as roughness error, achieve the effect of overcoming seam problem and eliminating phase error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

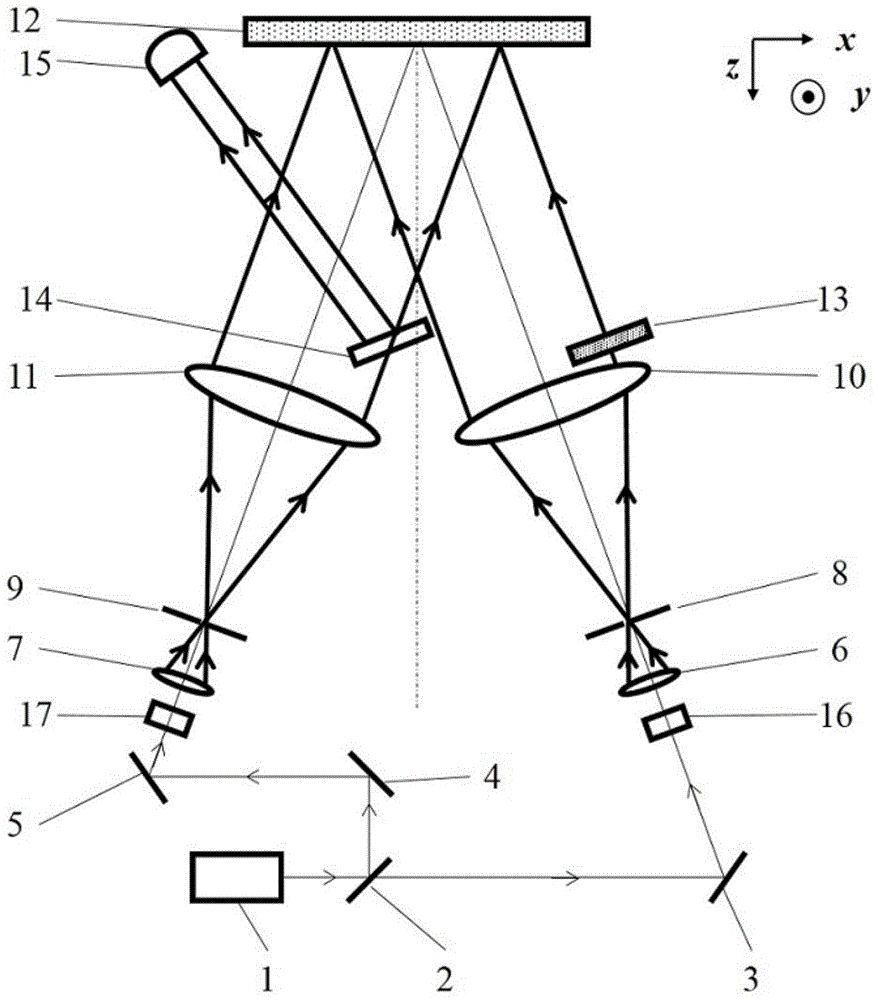

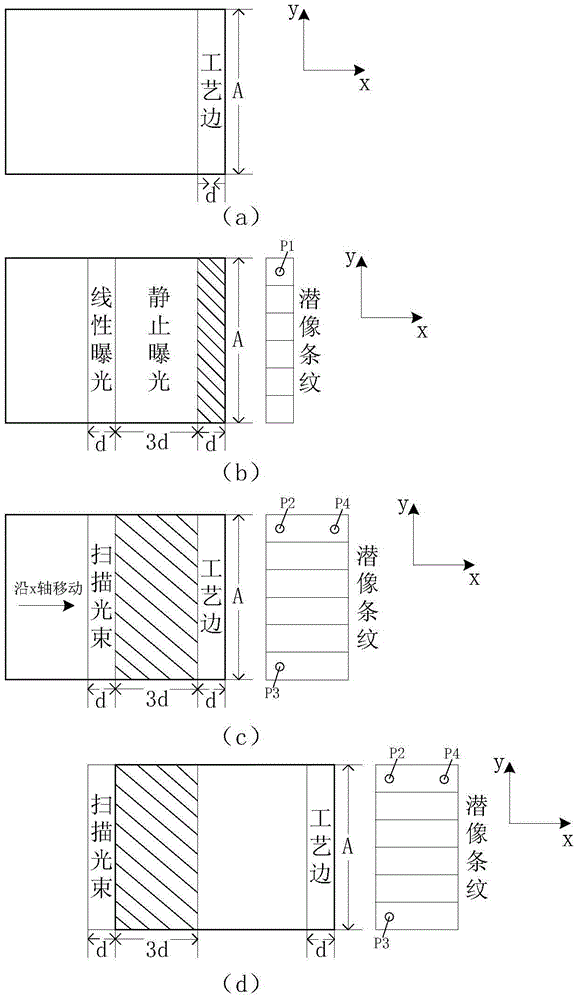

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0014] The working principle of the wide-beam scanning exposure method of the present invention is: on the basis of locking the phase and attitude of the exposure beam relative to the substrate, use a collimator lens aperture of 1 / 10 to 1 / 5 wide beam to scan and expose along the grating vector. The beam width can be adjusted according to actual needs. The narrow beam quality is good, but the exposure time is long; the wide beam quality is relatively poor, but the exposure time is short. During the exposure process, the interference field and the substrate are required to move strictly at the same speed and direction (the entire interference field does not move, but the phase of the interference field is shifting), otherwise the interference fringes recorded in the photoresist coated on the surface of the substrate will be smoothed out. When the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com