Complex space curved surface thin plate forming die face designing method taking springback compensation

A springback compensation and design method technology, applied in calculation, special data processing applications, instruments, etc., can solve problems such as many discrete points, a lot of time for fitting and repair, failure of springback compensation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] A design method for complex space curved thin plate forming die surface considering springback compensation, the basic process is as follows figure 1 As shown, the specific implementation process of the method is illustrated by taking the helical blade of a concrete mixer truck as an example. The established stamping model is as figure 2 As shown, the uppermost curved surface represents the upper die, the one with two guide pillars represents the lower die, and the middle one represents the blank. The parameter settings in ABAQUS are shown in Table 1.

[0068] (1) Simulate the ideal product shape h L For the stamping process of the die surface, the joint stress of the thin plate before springback is obtained F L , and its stress cloud diagram is as follows image 3 shown;

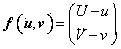

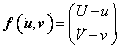

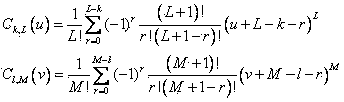

[0069] (2) if Figure 4 As shown, using the nodal stress matrix F L multiply diagonal matrix α n owned- α n F L As the prestress is loaded on the sheet node, calculate the sheet in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com