Accident decay heat discharge system for non-symmetric distribution of large pool type sodium-cooled fast reactors

A waste heat removal system and sodium-cooled fast reactor technology, which are applied in cooling devices, reactors, and greenhouse gas reduction, etc., can solve the problems of not taking into account the function of waste heat removal in economical operation, and high reactor operating costs, so as to alleviate the accident process and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

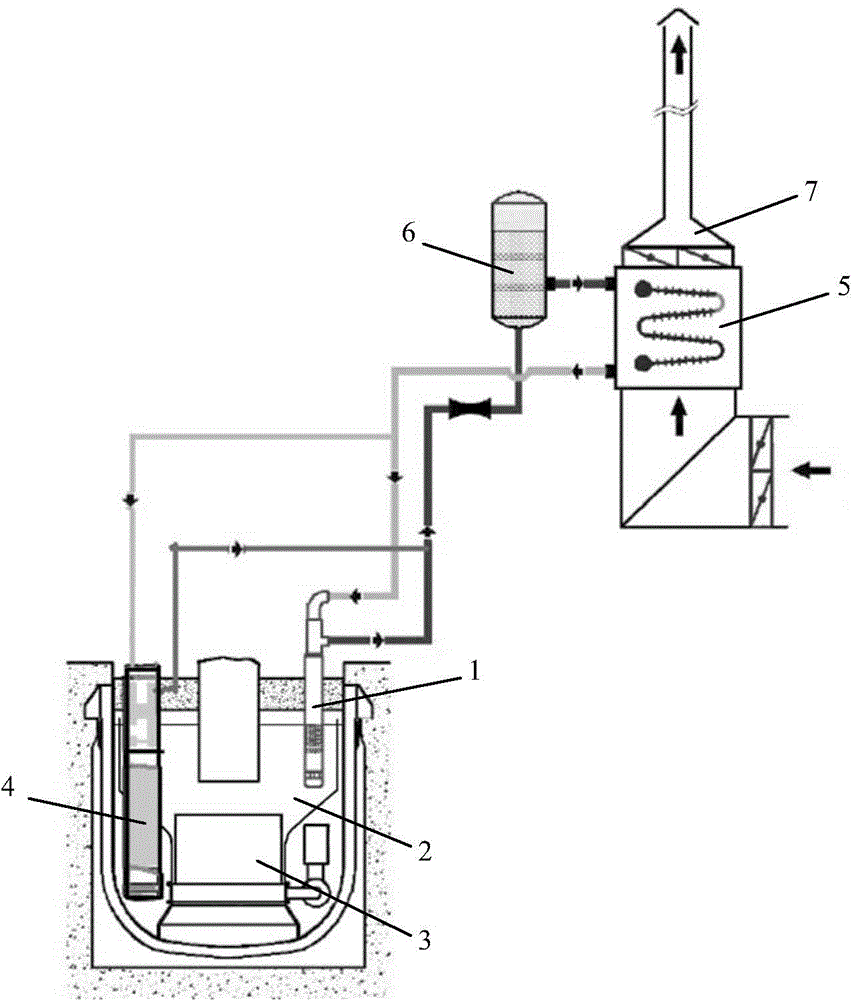

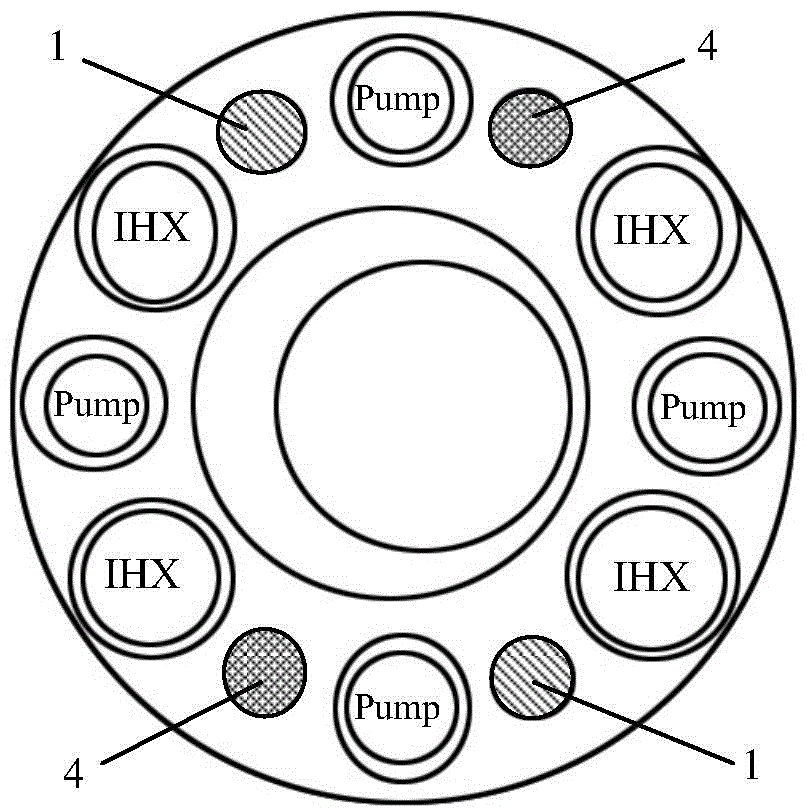

[0019] The accident waste heat removal system provided by the present invention is arranged in the primary loop system of the fast reactor. The waste heat removal system mainly consists of an independent heat exchanger located in the hot sodium pool, a through heat exchanger located between the cold and hot sodium pools, intermediate loop pipes and It consists of a sodium-air heat exchanger located outside the stack body. Such as figure 1 As shown, the independent heat exchanger 1 and the through heat exchanger 4 are respectively connected to the sodium-air heat exchanger 5 arranged outside the reactor through pipelines, and the position of the sodium-air heat exchanger 5 is higher than that of the independent heat exchanger. The front end of the sodium inlet of the sodium-air heat exchanger 5 is provided with a sodium buffer tank 6, and the outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com