Conductive paste and method for manufacturing same

A manufacturing method and technology of conductive paste, applied in the direction of cable/conductor manufacturing, circuit, conductive material dispersed in non-conductive inorganic materials, etc., can solve the problems of disconnection of electrode network wire, reduction of conversion efficiency of solar cells, increase of resistance, etc. achieve high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Herein, the present invention will be described in detail with respect to specific embodiments and viewpoints of the present invention. Such descriptions are for explaining the structure or step flow of the present invention, and are used for illustration rather than for limiting the claims of the present invention. Therefore, in addition to the specific and preferred embodiments in the description, the present invention can also be widely used in other different embodiments.

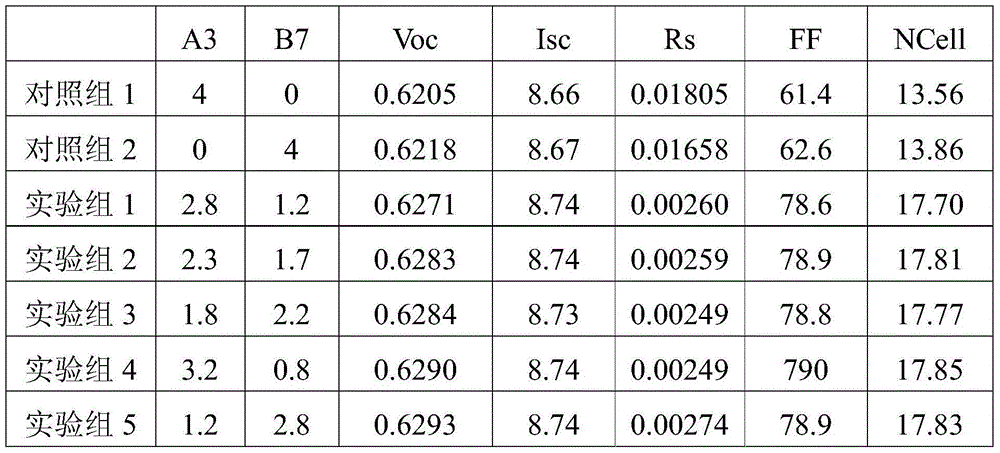

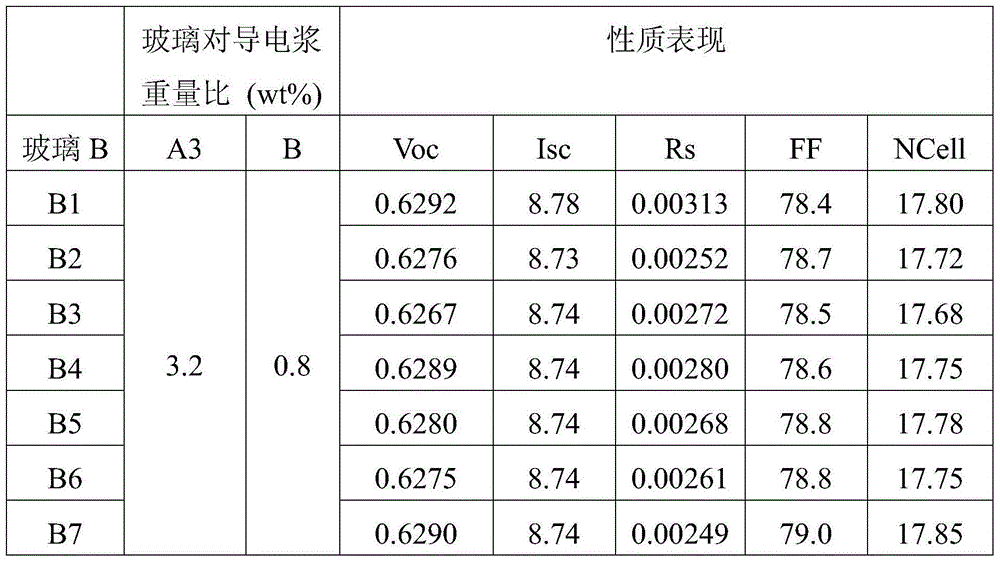

[0019] The present invention provides a conductive paste that can improve the conversion efficiency of solar cells. In an embodiment, it can be used to form the front electrode (ie, the light-receiving surface) of the solar cell substrate. The conductive paste proposed by the invention can be sintered at a low sintering temperature, so that the finished solar cell has high conversion efficiency. Hereinafter, an example is used to describe the implementation of the present invention, but the appli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com