Automatic detection machine for cell packaging

A battery packaging and testing machine technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, measuring electricity and other directions, can solve the problems of large space occupied by equipment, low production efficiency and high production cost, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

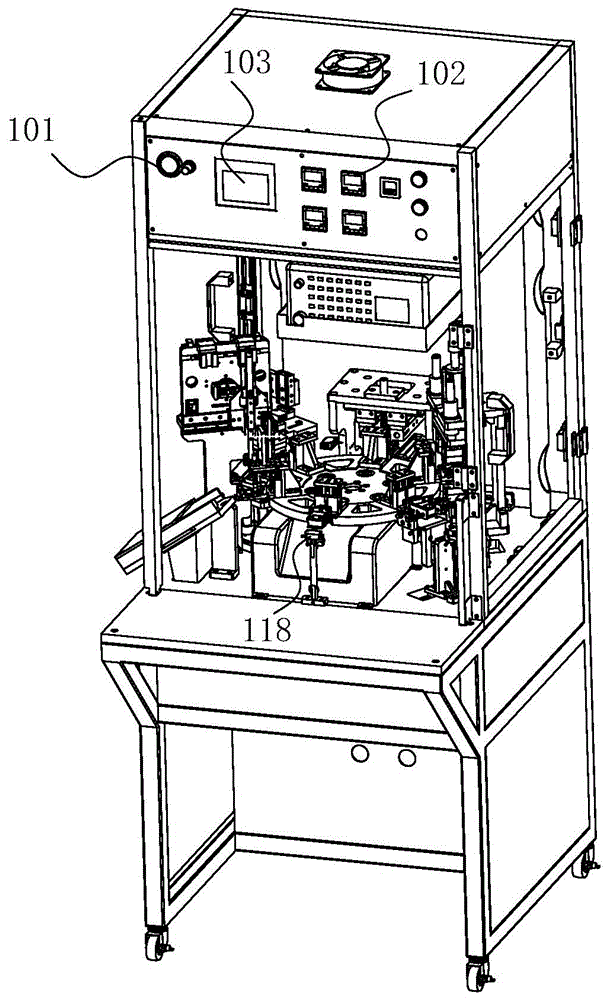

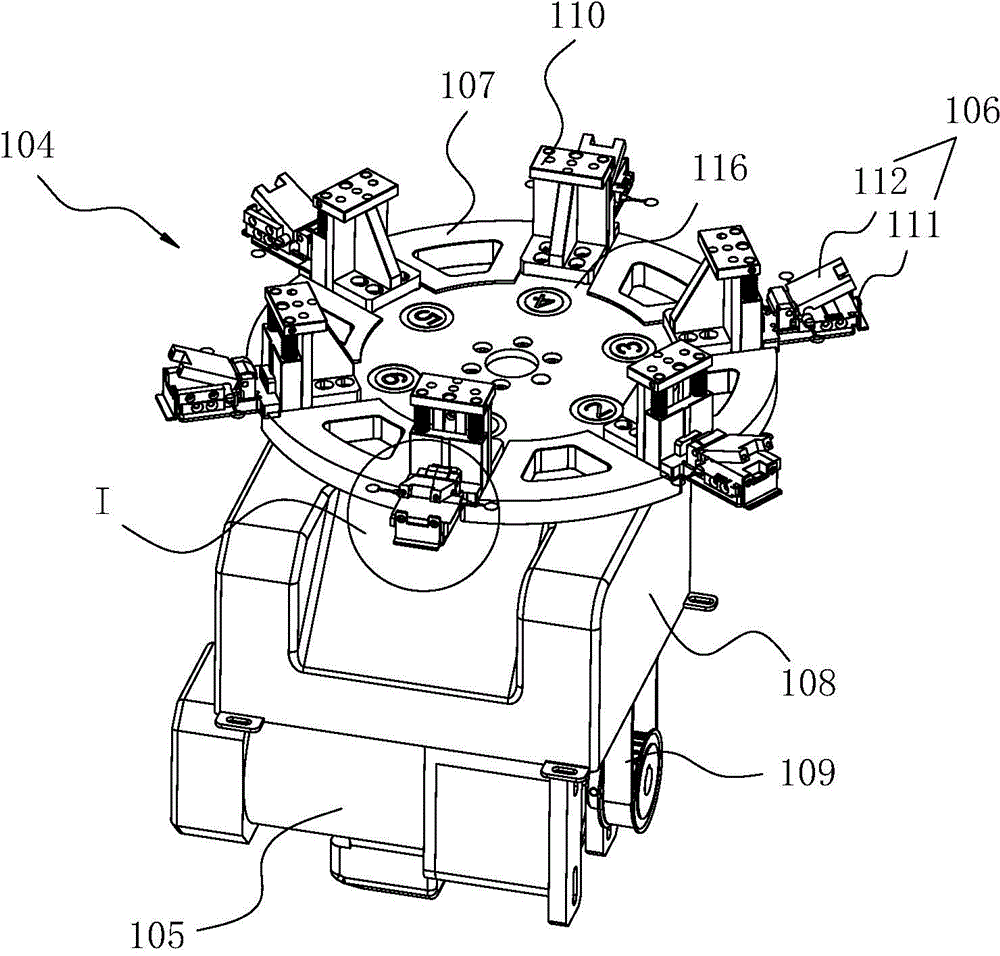

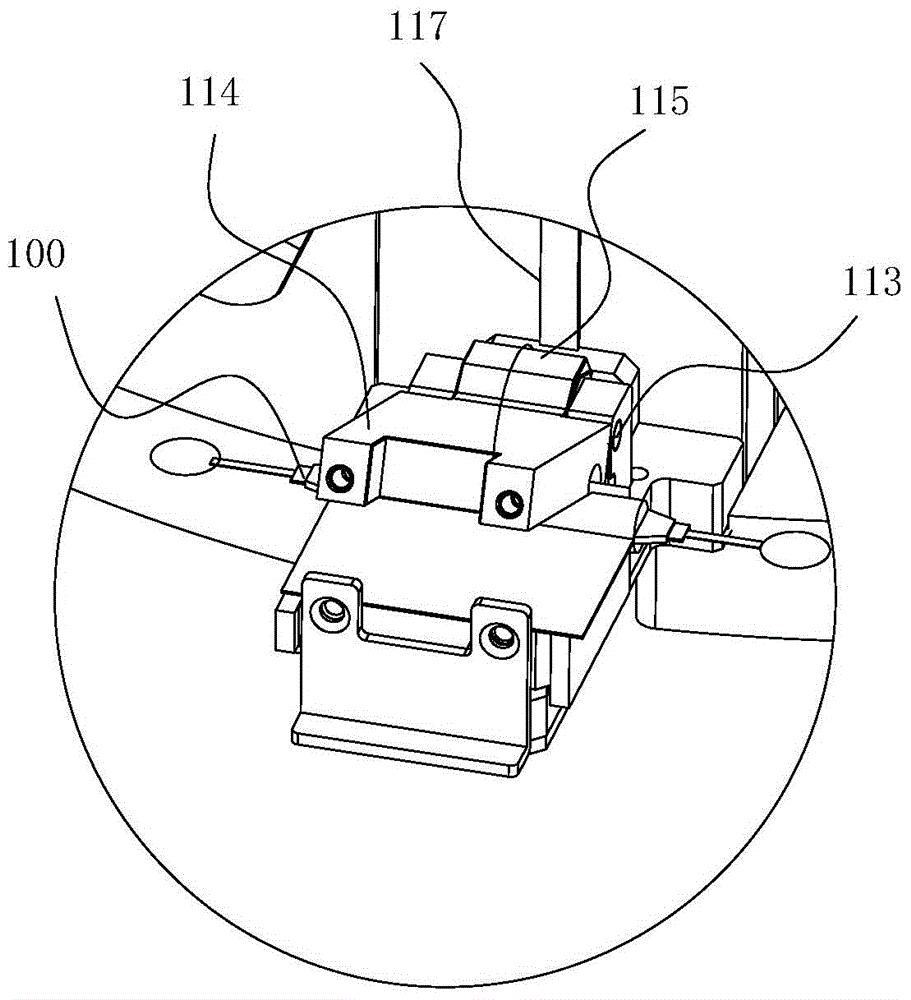

[0035] Such as Figure 1-9 As shown, in this embodiment, an automatic detection machine for battery packaging according to the present invention includes a workbench and a control system arranged above the workbench. The control system includes a packaging pressure regulating device 101 and a packaging temperature regulating device 102. and a display screen 103 for viewing data values. On the workbench and between the workbench and the control system, there is an encapsulation turntable 104. The encapsulation turntable 104 is driven by the turntable drive device and can be installed on the workbench to rotate relative to the workbench. The edge of the encapsulation turntable 104 is evenly arranged with six The encapsulation jig 106, the periphery of the encapsulation turntable 104 corresponds to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com