Conductive concrete grounding part employing branch pipe and manufacturing device for conductive concrete grounding part

A technology of conductive concrete and grounding components, which is applied in the manufacture of contacts, protective grounding/shielding devices for connecting components, and materials for connecting contacts, etc., which can solve the problems of reduced manufacturing efficiency, inability to obtain grounding effects, and failure to develop mass production. , to enhance the sturdiness and prolong the life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

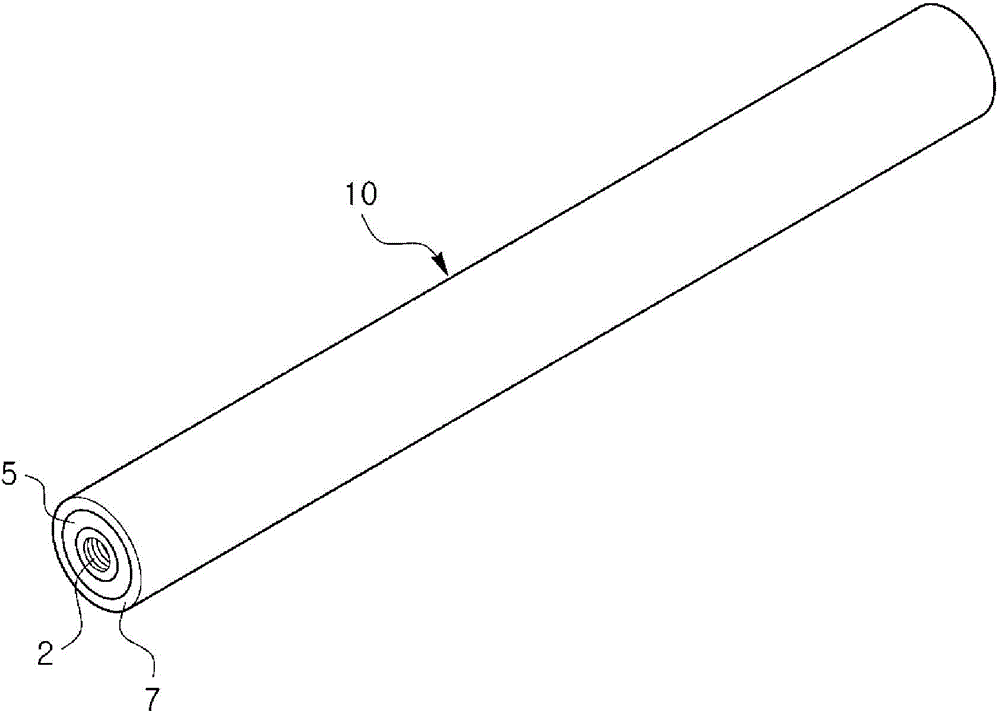

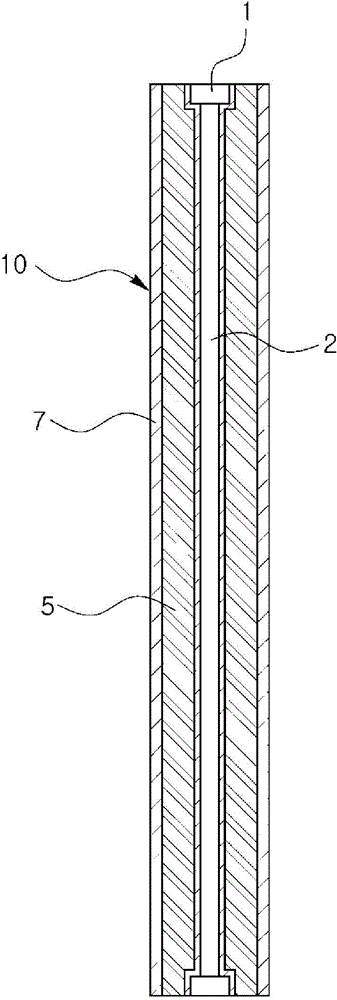

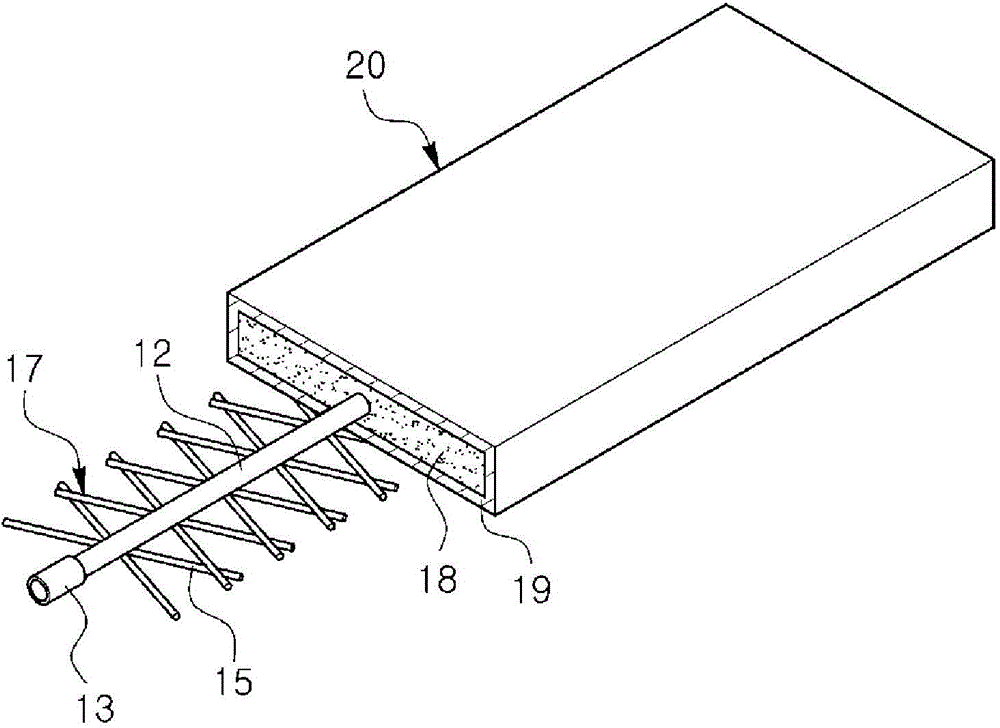

[0033] figure 1 It is a cross-sectional view illustrating the constitutional state of the cylindrical ground member forming the present invention, figure 2 To form a longitudinal sectional view of a cylindrical ground member, image 3 A partially cut sectional view illustrating a structural state forming a flat plate-shaped ground member, Figure 4 It is a longitudinal cross-sectional view of the ground member formed into a flat plate shape.

[0034] Such as figure 1 and figure 2 As shown, the grounding member of the present invention is roughly divided into cylindrical shape and flat plate shape.

[0035] First, if figure 1 As shown, the cylindrical grounding part 10 is composed of a hollow pipe 2, a conductive concrete 5 and a branch pipe 7, wherein the conductive concrete 5 is coated on the outer surface of the hollow pipe 2 with a uniform thickness; The branch pipe 7 is coated on the outer surface of the conductive concrete 5 .

[0036] The hollow tube 2 is made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com