Turnover cable pay-off vehicle and application method thereof

A technology of overturning cables and pay-off carts, applied in cable laying equipment and other directions, can solve the problems of single product performance, inability to realize self-loading and unloading of cables on the construction site, etc., and achieve the effect of reducing labor intensity, simple structure, and ensuring safe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

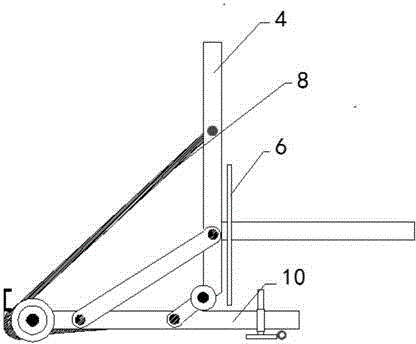

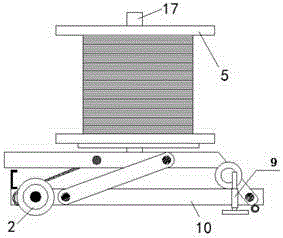

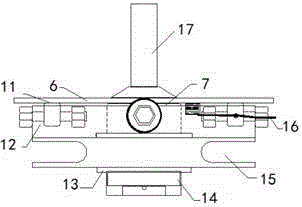

[0024] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the reversible cable pay-off car, the chassis 10 is connected to the hoist formed by the load-bearing wheel 18, the universal wheel 19, the support jack 9, the worm wheel 2, and the worm 1; the reversible frame 4 is connected with a load-bearing bearing 7; the reversible frame 4 passes Flip the support bar to connect the bottom frame 10;

[0025] Worm wheel 2 connects worm screw 1 and the winch traction wire rope 8 that forms can make overturn frame 4 (comprising the turntable mechanism that can move up and down) stand up vertically, because underframe 10 is equipped with load-bearing wheel 18 and universal wheel 19, can put cable car flexibly Push it to the front of the standing cable reel 5, adjust the turntable mechanism that can move up and down, make the central axis of the turntable align with the center hole of the cable reel 5, push the cable car, insert the cable car and the ...

Embodiment 2

[0041] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the reversible cable pay-off vehicle mainly consists of an underframe 10 (including a load-bearing wheel 18, a universal wheel 19, a hoist composed of a support jack 9, a worm wheel 2, and a worm 1, etc.), an overturning frame 4 (including a vertically movable turntable mechanism),

[0042] The winch traction wire rope 8 that worm gear 2, worm screw 1 is formed can make overturn frame 4 (comprising the turntable mechanism that can move up and down) erect vertically, because underframe 10 is equipped with load-bearing wheel 18 and universal wheel, 19 can be used for cable pay-off car Flexibly push to the front of the standing cable reel 5, adjust the up and down movable turntable mechanism so that the central axis of the turntable is aligned with the center hole of the cable reel 5 and push the cable car to insert the cable car and the turntable into the cable reel completely.

[0043...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com