Spiral bit capable of conveniently drilling into soil of deep scarification cultivation machine

A technology of auger bit and cultivator, which is applied to agricultural machinery and implements, applications, plows, etc. It can solve the problems of high resistance to entry into the soil, short service life, and low practicability, so as to prolong the service life, avoid wear and tear, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

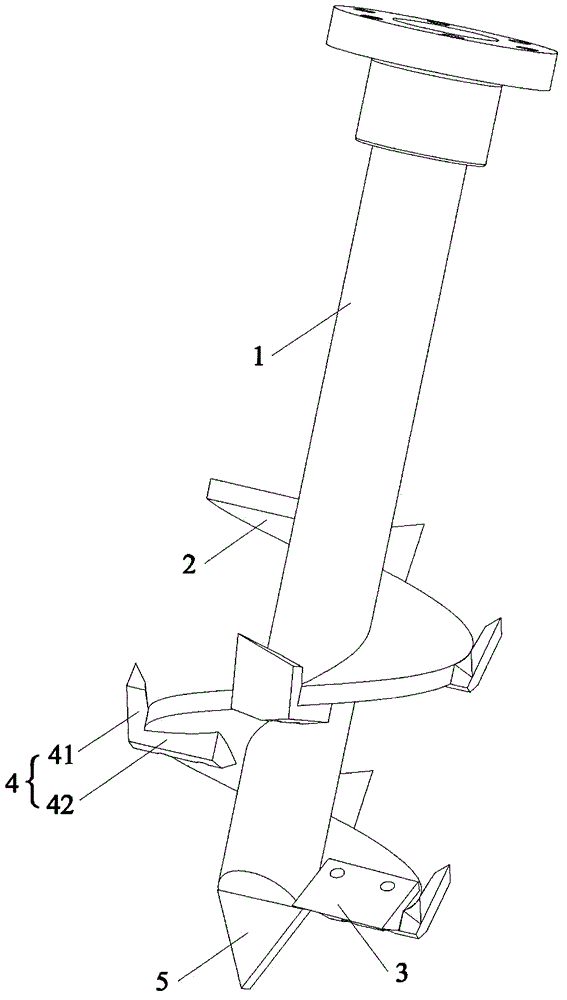

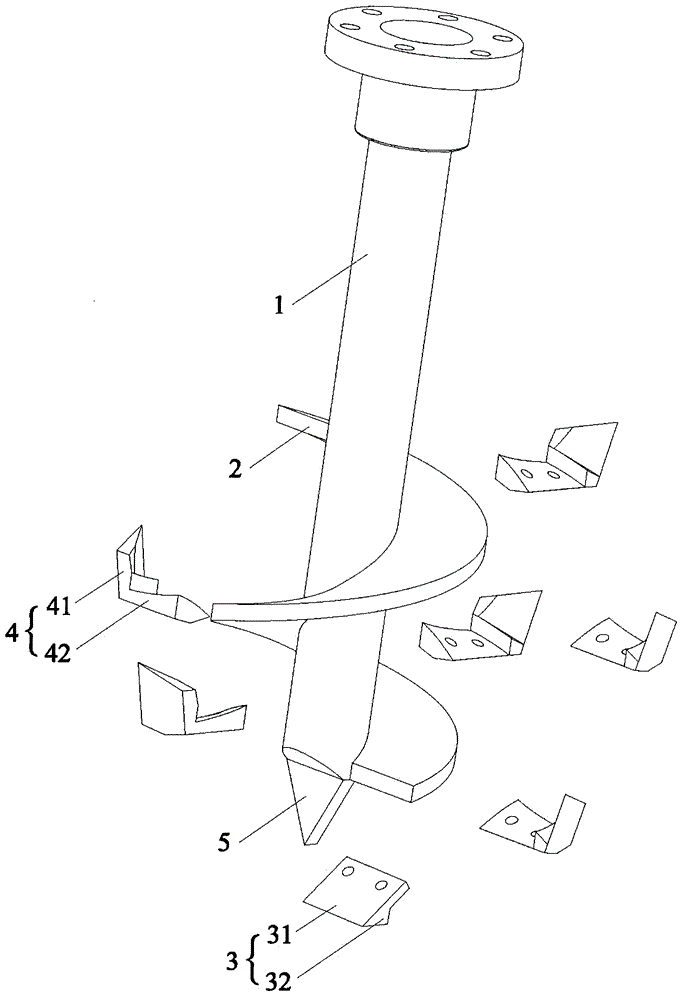

[0023] Such as figure 1 , figure 2 As shown, the direction of this embodiment is figure 1 The placement direction of the auger bit of the subsoil tillage machine that is easy to enter the soil shown in the present embodiment is an auger bit of the subsoil tillage machine that is easy to enter the soil. It includes a drill rod 1, a spiral blade 2, and a spiral blade 2 around Located at the lower part of the drill pipe 1, it also includes a soil-entering blade 3, which is arranged at the tail of the spiral blade 2 and located on the lower surface of the spiral blade 2. The invention has a simple structure. During farming operations, the drill rod 1 moves forward with the subsoiling tiller while rotating. Because the bottom surface of the tail of the spiral blade 2 is provided with a soil inserting blade 3, it is convenient for the drill rod 1 to enter the soil while rotating. It can effectively prevent the spiral blade 2 from being worn out, prolong the service life of the spira...

Embodiment 2

[0032] The difference between this embodiment and the first embodiment is that: in this embodiment, the diameter of the spiral blade 2 gradually changes from large to small along the direction of the drill rod 1 toward the bottom end of the drill rod 1. This embodiment breaks through the traditional spiral blades 2 with the same upper and lower diameters, and adopts the spiral blades 2 with the upper and lower diameters, which not only enhances the soil penetration rate of the spiral drill bit of the present invention, but also makes the soil on the surface of the ground smash relatively The deep soil is crushed finely and meets agronomic requirements.

[0033] The other structure of this embodiment is the same as that of the first embodiment, and will not be repeated here.

Embodiment 3

[0035] The difference between this embodiment and the first embodiment is that: in this embodiment, the cross section of the drill rod 1 is polygonal. The polygon can be triangle, quadrilateral, pentagon or hexagon, etc. The drill rod 1 is polygonal, so that when the drill rod 1 rotates, the angle of the polygon is equivalent to the cutter, which has the function of cutting soil, so the subsoil tiller When walking forward, the polygonal drill rod 1 can move forward while loosening the soil, further improving the farming efficiency. The polygon is not limited to a triangle, a quadrilateral, a pentagon or a hexagon, as long as the drill rod 1 is rotated to facilitate soil cutting.

[0036] The other structure of this embodiment is the same as that of the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com