Anti-overflow control system

A control system and anti-overflow technology, which is applied in the direction of anti-overflow, etc., can solve the problems of increasing the workload of users to clean the stove, the boiling soup is very easy to overflow the pot, and does not have the anti-overflow function, so as to improve the economic benefits of the enterprise , Avoid the effect of durability and sealing, easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

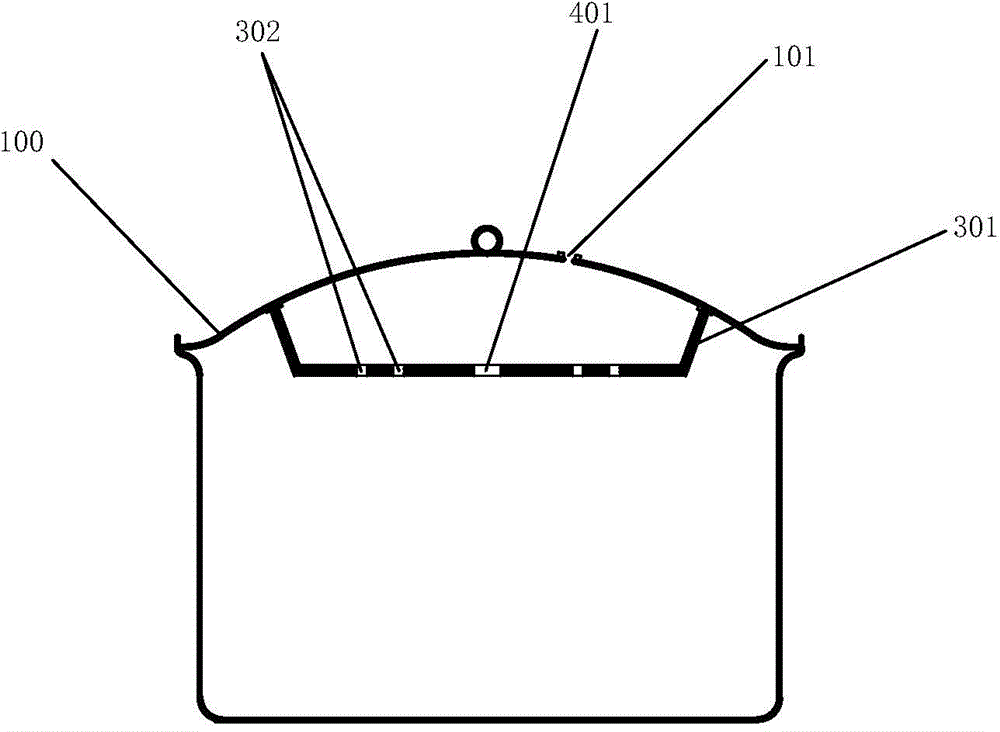

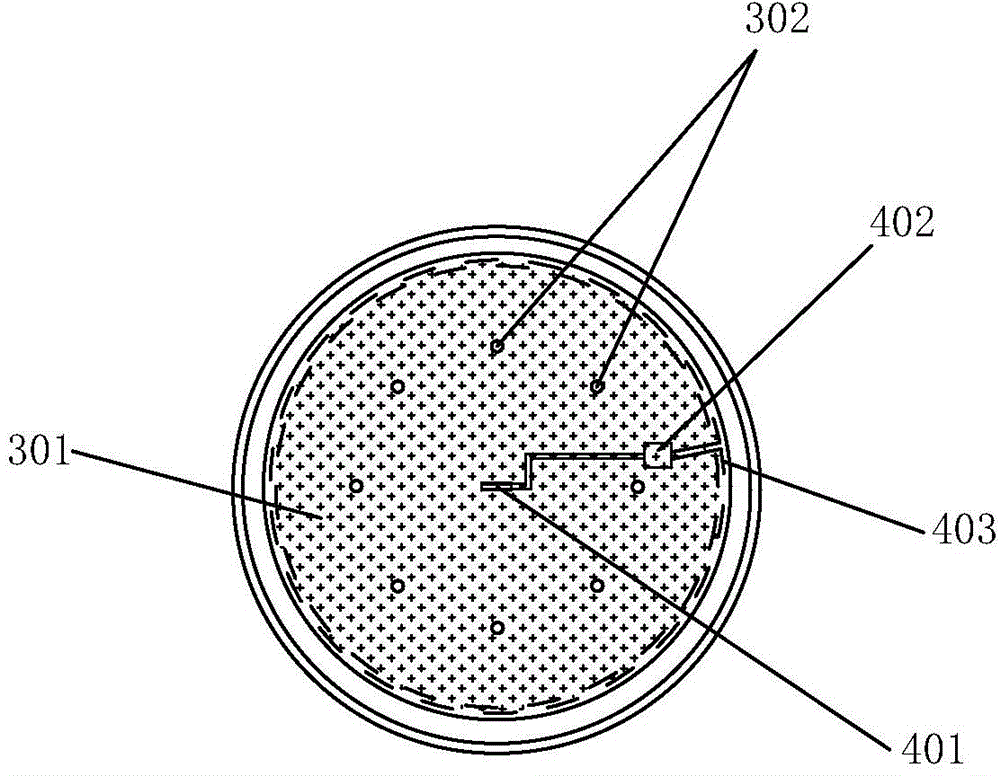

[0029] Such as figure 1 with figure 2 As shown, the anti-overflow detection bracket 301 is a disc-shaped bracket, the bottom surface of the disc-shaped bracket is in the pot body, and the soup in the pot will not overflow to the side of the pot body. When the soup reaches the anti-overflow detection bracket 301, The cooker control device 200 will control the firepower to be turned down, so that the soup in the pot can be prevented from overflowing more effectively.

[0030] The antenna 403 is embedded in the anti-overflow detection bracket 301. Since the entire bracket is inside the pot, the pot cover 100 is made of non-metal, so that the temperature information can be better transmitted to the cooker control device 200, reducing the amount of metal used when transmitting information. interference.

[0031] The anti-overflow holes 302 are more than one, and the anti-overflow holes 302 are evenly distributed on the anti-overflow detection bracket 301. The evenly distributed ...

Embodiment 2

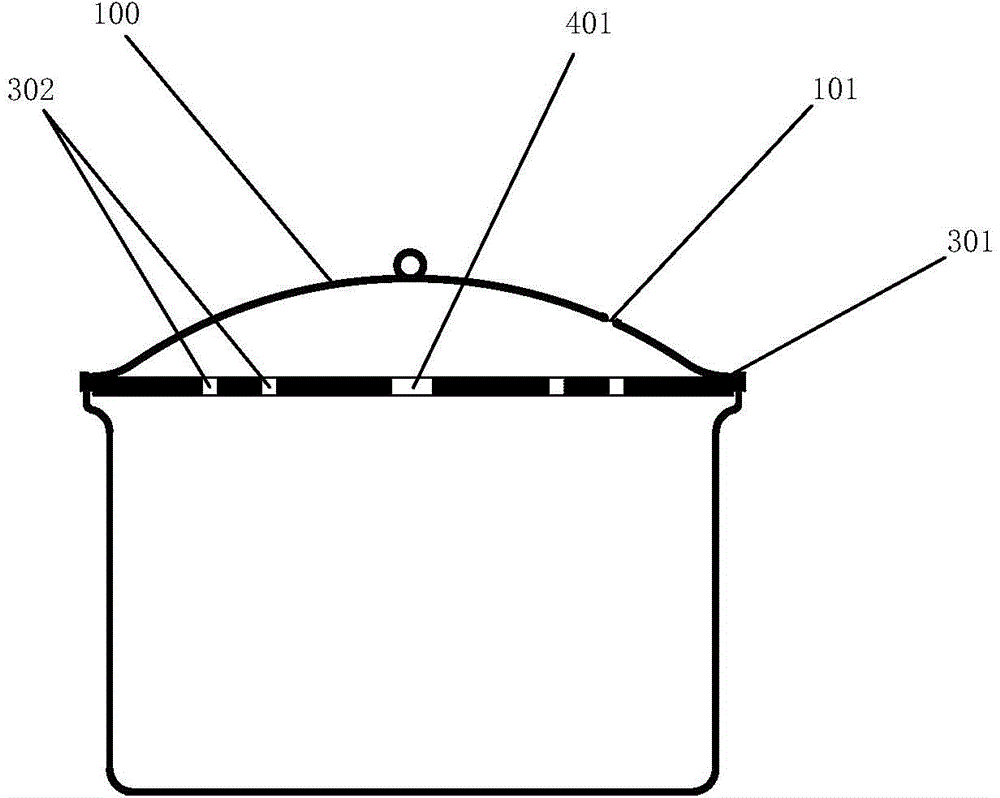

[0036] Such as image 3 with Figure 4 As shown, the anti-overflow detection support 301 is a circular surface-shaped support, the anti-overflow detection support is covered on the pot cover 100, and the antenna 403 is placed on the outer edge of the anti-overflow detection support 301 in a ring shape, which ensures the gain of the antenna 403. The edge of the anti-overflow detection bracket 301 has a certain thickness to reduce the influence of metal on the antenna 403, so that the pot cover can be made of metal; on the one hand, it can be suitable for pots of different materials; on the other hand, one bracket can be used for multiple pots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com