Honing head

A honing head and honing technology, applied in the direction of honing tools, etc., to achieve the effect of slowing mutual impact, preventing relative displacement and ensuring synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

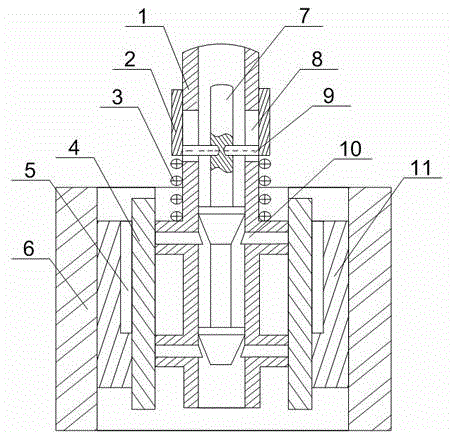

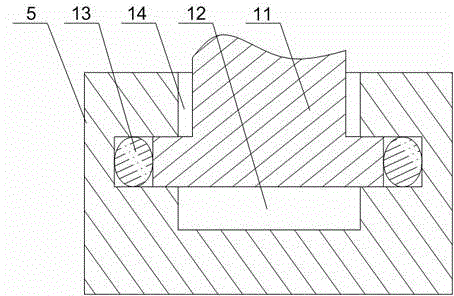

[0023] like figure 1 and figure 2 As shown, this embodiment includes a hollow honing body 1 and a plurality of spacers 4, a plurality of transition holes are opened on both sides of the honing body 1, and an adjustment pin 10 is fixed on one side of the spacer 4, and the adjustment The pin 10 cooperates with the gap 14 of the transition hole, and a fixing seat 5 is installed on the other side of the cushion block 4, and a groove 12 is provided on the fixing seat 5, and blind holes are respectively arranged on the two side walls of the groove 12, and the cross section is The main body of the horizontal part of the T-shaped oil stone 11 is placed in the groove 12 and the two ends of its horizontal part are placed in the blind hole. There is a gap 14 between the vertical part of the oil stone 11 and the groove 12, and in the blind hole There is a rubber strip 13 between the horizontal part of the whetstone 11; the inside of the honing body 1 is slidably provided with an adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com