Water nozzle for high-speed cam grinder

A technology of high-speed cams and faucets, applied in grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc., can solve the problem of short contact arc length between coolant jet and grinding wheel, reduced grinding speed, and difficulty in adapting to concave surfaces Problems such as cams, to achieve significant cooling effect, improve quality, and prevent burns or cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

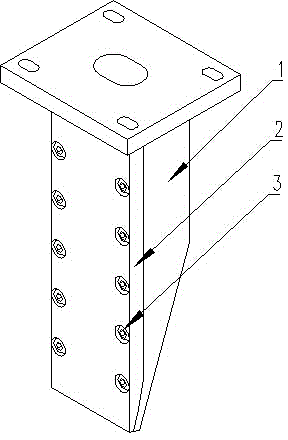

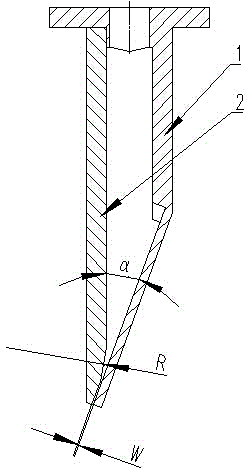

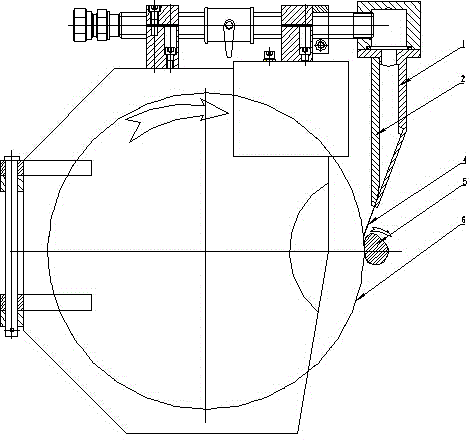

[0011] Further illustrate the present invention in conjunction with accompanying drawing, as shown in the accompanying drawing, the present invention is by faucet body 1, the faucet cover plate 2 that cuts out from faucet body 1, cover plate 2 is fixed on the faucet body 1 with screw 3, The nozzle inclination angle α is 10~30°, and the width W of the nozzle section is 0.8~1.2mm. The water nozzle obliquely sprays the coolant 4 onto the grinding wheel 6 in front of the cam 5 .

[0012] When the present invention is in use, the coolant is sprayed toward the surface of the grinding wheel at an angle of 10-30° to prevent the high-speed airflow driven by the grinding wheel from entering the grinding zone; When the curvature radius of the grinding profile is very large, especially for the concave cam, the position of the grinding point can be changed greatly; the coolant ejection speed is generally much lower than the grinding wheel linear velocity, and a layer of lower-velocity cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com