Environmental-friendly synthetic paper production method based on two-way stretching process

A technology of biaxial stretching and production method, which is applied in the field of synthetic environmental protection paper production process and its production device, can solve the problems of low transverse strength, thick paper product, low production capacity, etc., so as to ensure the quality of finished products, ensure effective improvement, and simplify control effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

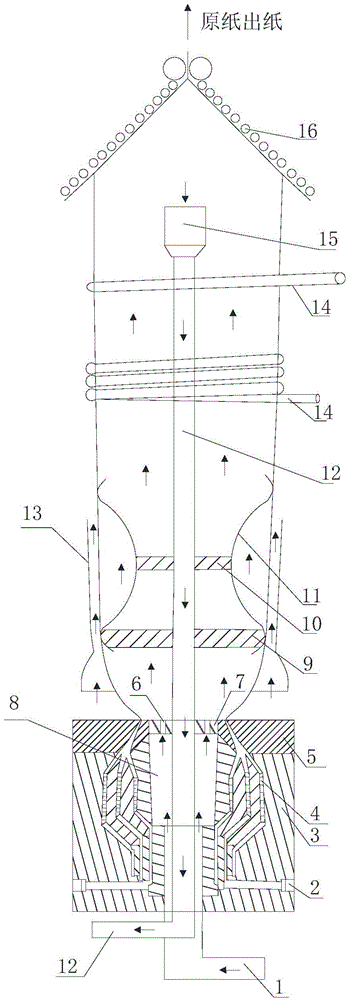

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0054] Such as figure 1 Shown, the synthetic environment-friendly paper production method based on biaxial stretching process of the present invention, comprises mixed particle granulation operation and papermaking operation, is characterized in that:

[0055] The granulation process of the above-mentioned mixed particles comprises the following steps: by mass parts, respectively weigh 75-85 parts of calcium carbonate powder with a particle size of 600-1200 mesh, 15-25 parts of resin, 1-2.5 parts of coupling agent, lubricant Add 2-3.5 parts and 1-2.5 parts of desiccant to a temperature-controlled mixer, control the temperature at 40-65°C, and stir for 10 minutes until evenly mixed;

[0056] Put the uniformly mixed material into the twin-screw granulator, extrude with honey, heat cut and air-cooled, and complete the granulation of the mixed particles; among them,

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com